Drum-type automatic insect breeding machine

A drum-type, automatic technology, applied in the field of insect breeding, can solve the problems of adverse effects on workers' health, low efficiency and high cost, and achieve the effects of improving practicability and convenience, increasing work efficiency and reducing adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

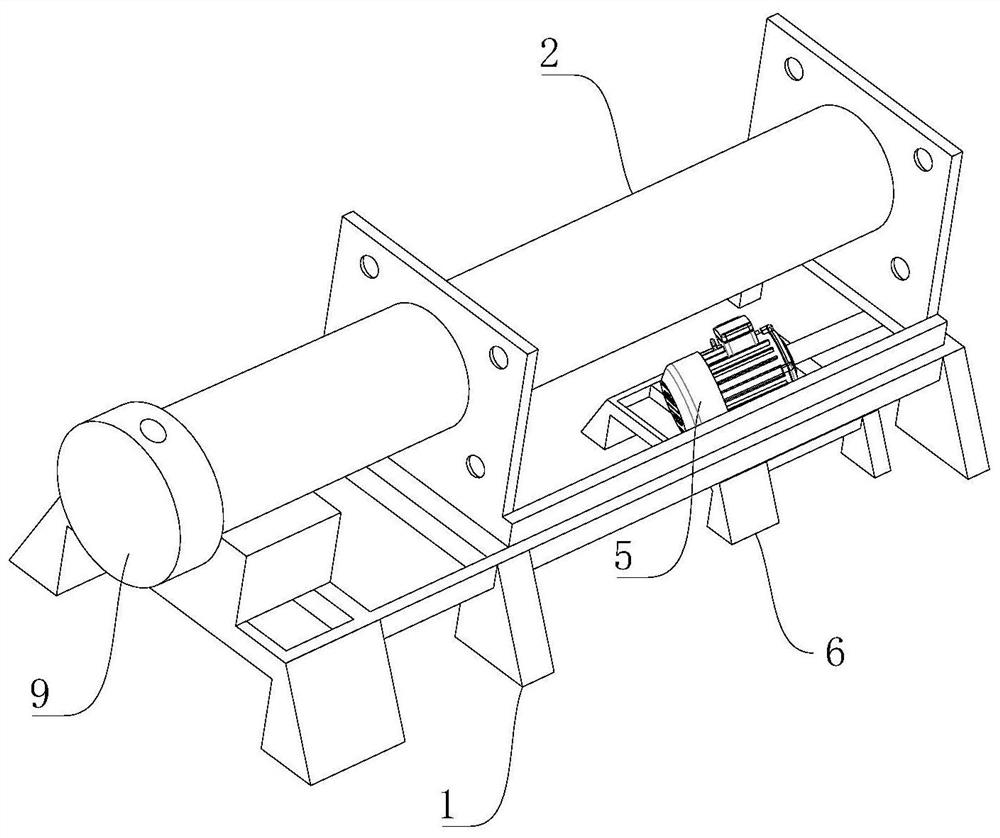

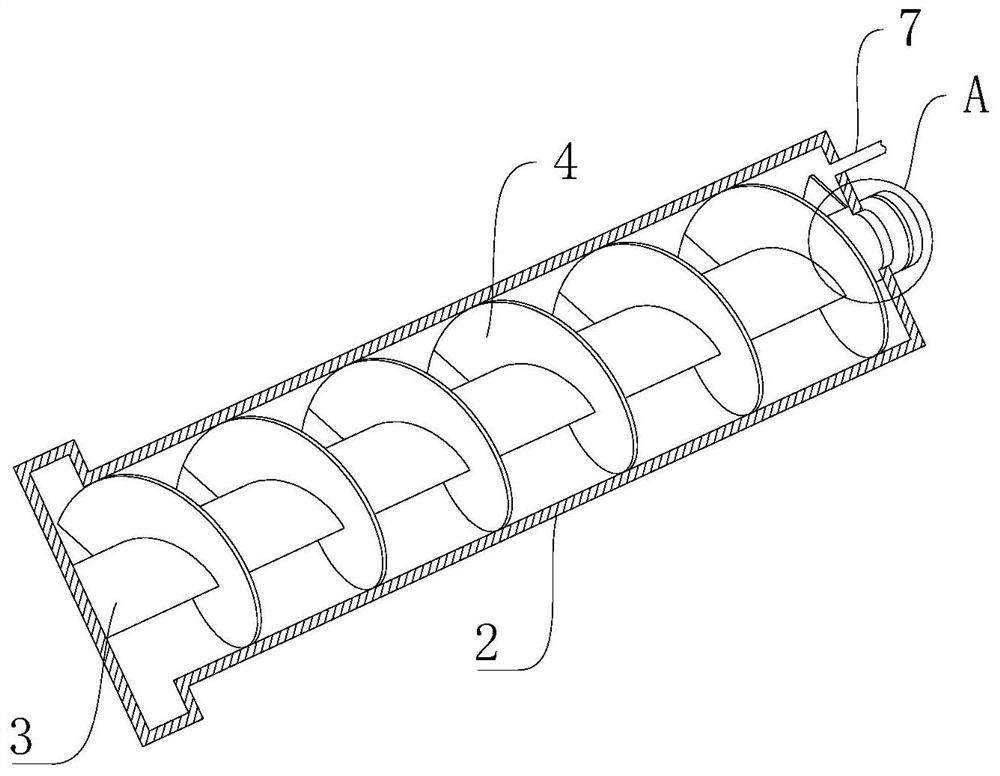

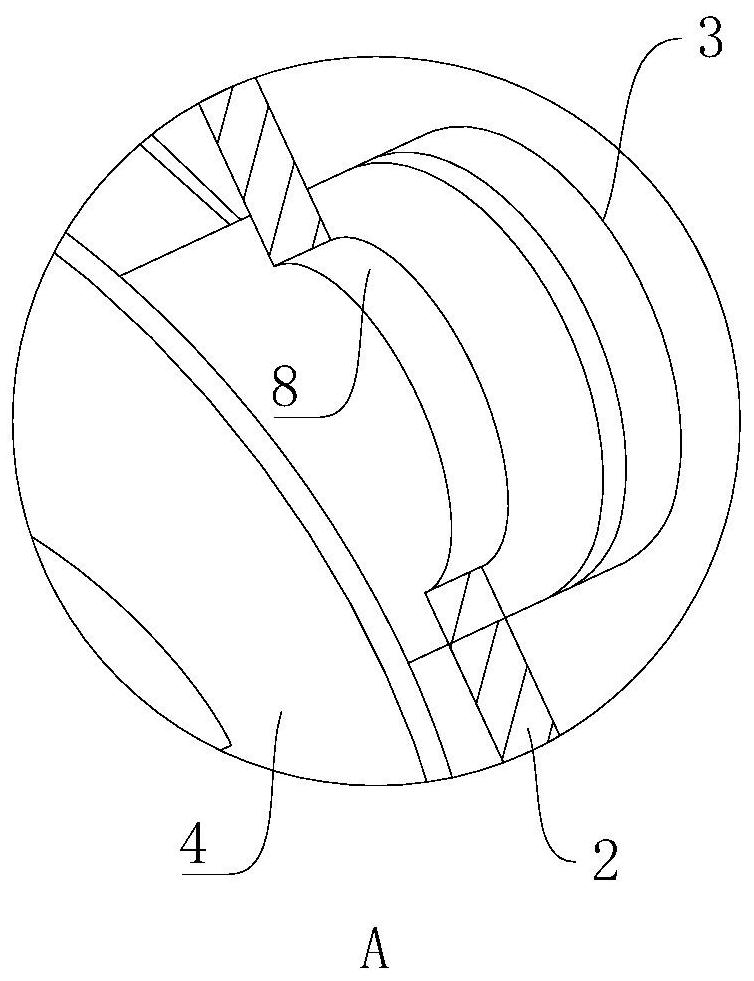

[0037] Please refer to Figure 1-Figure 3 , the present embodiment provides a drum-type automatic insect breeding machine, which includes a mounting base 1 and a breeding box 2 located above the mounting base 1. The inside of the breeding box 2 is hollow and has a columnar structure, that is, the horizontal width of the inner space of the breeding box 2 The cross-section is circular; in the breeding box 2, there are aquaculture components extending along its length direction, one end of the aquaculture component is rotationally connected with the inner wall of the aquaculture box 2, and the other end extends out of the aquaculture box 2 to connect with the driving mechanism, and the driving mechanism is used to drive The breeding assembly rotates; one end of the breeding box 2 is also provided with a feed port and a discharge port.

[0038] When in use, the insects cultivated can be attached to the inner wall of the breeding box 2 and the outer wall of the breeding component, ...

Embodiment 2

[0051] Please refer to Figure 1-Figure 4 , in this embodiment, the above-mentioned also includes a processor, the processor is connected to the motor 5, and the operation of the motor 5 is controlled by the processor; the processor is also connected with a touch screen and an electric valve; the electric valve is located at the port of the feed port to control the feeding; the touch screen is used to operate, set and control the opening and closing states of the motor 5, the fan and the electric valve, as well as the duration and time of opening. Through the control of the processor and the operation and setting of the touch screen, the electric valve can be opened regularly to add food, and when the electric valve is opened, the motor 5 rotates accordingly, and the food is transported to the breeding box 2 Everywhere in the interior; and the opening of the fan can also be controlled by the setting of the touch screen when it is turned on, how long it is, and when it is turne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com