An ultra-thin zero spherical aberration implantable lens for myopia

A lens and lens technology, which is applied in the field of ultra-thin zero-spherical aberration implantable myopia lens design, can solve the problems of sacrificing the size of the effective optical zone, difficulty in further increasing the safety gap between the lens and the natural lens, and thick edges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

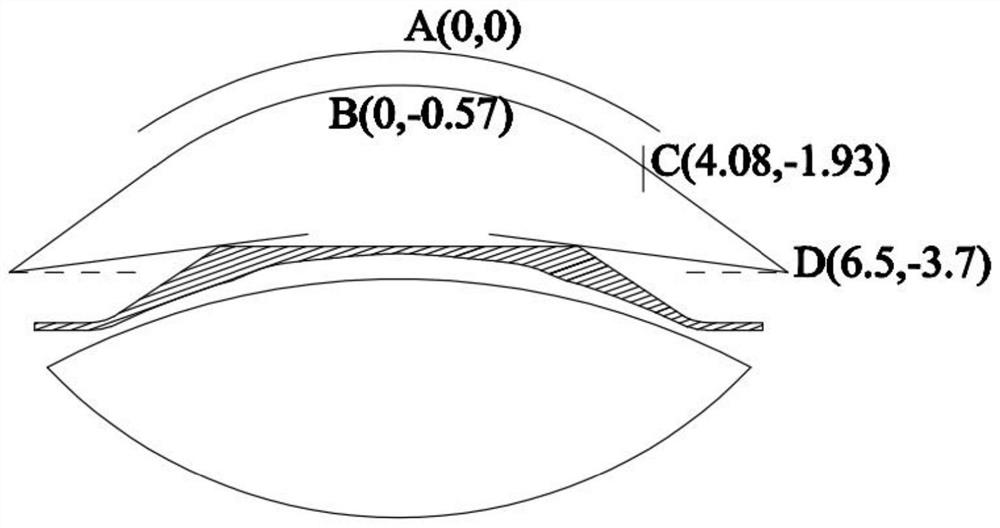

[0029] The design material of Example 1 is hydrophilic polymethacrylate, the refractive index of the material is 1.46, the Abbe number is 45; the design optical power is -12D; the design wavelength λ is 0.546um; the diameter of the optical zone is 6.0mm; The center thickness is 0.11mm.

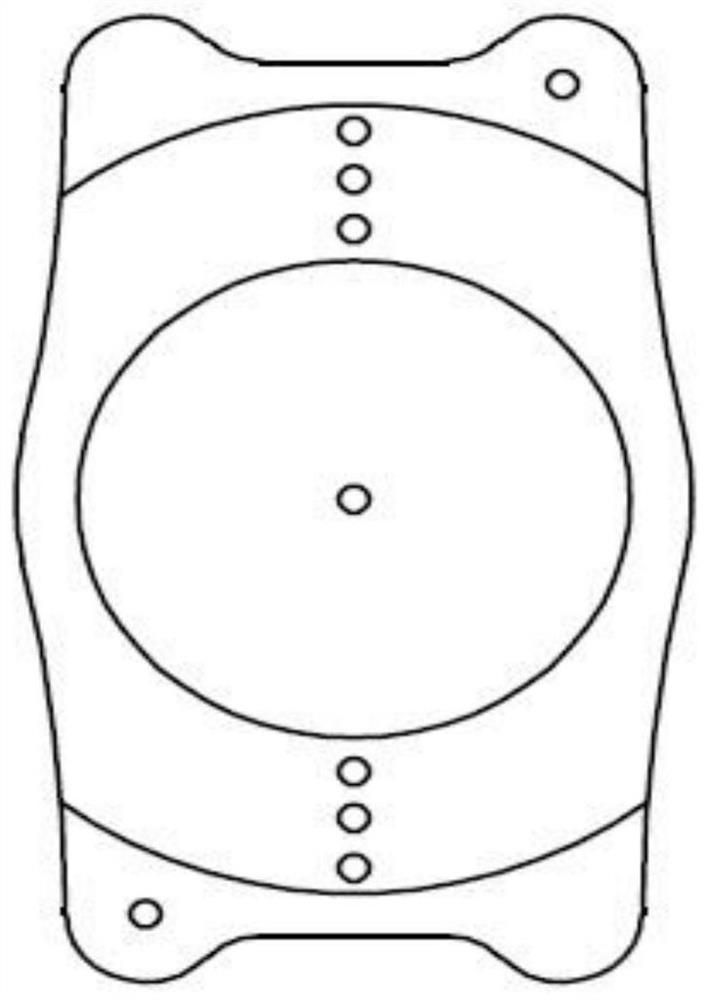

[0030] like figure 1 As shown, in the front view of Embodiment 1, Embodiment 1 includes an optical zone and a plate-shaped support haptic along the edge of the optical zone of the lens, and the optical zone of the lens is a plano-concave circular lens, consisting of two optical surfaces, the front surface ( The surface close to the iris after implantation) is a plane, and the posterior surface (the surface close to the natural lens after implantation) is a rotationally symmetric free-form surface;

[0031] The method for determining the free-form surface: taking the vertex of the optical surface as the origin O, and taking the optical axis as the coordinate Z axis, an arbitrary space rectang...

Embodiment 2

[0055] The design material of Example 2 is hydrophilic polymethacrylate, the refractive index of the material is 1.46, the Abbe number is 45; the design optical power is -18D; the design wavelength λ is 0.546um; the diameter of the optical zone is 5.5mm; The center thickness is 0.11mm.

[0056] like figure 1 As shown, in the front view of Embodiment 2, Embodiment 2 includes an optical zone and a plate-shaped support haptic along the edge of the optical zone of the lens, and the optical zone of the lens is a plano-concave circular lens, consisting of two optical surfaces, the front surface ( The surface close to the iris after implantation) is a plane, and the posterior surface (the surface close to the natural lens after implantation) is a rotationally symmetric free-form surface;

[0057] The method for determining the free-form surface: taking the vertex of the optical surface as the origin O, and taking the optical axis as the coordinate Z axis, an arbitrary space rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com