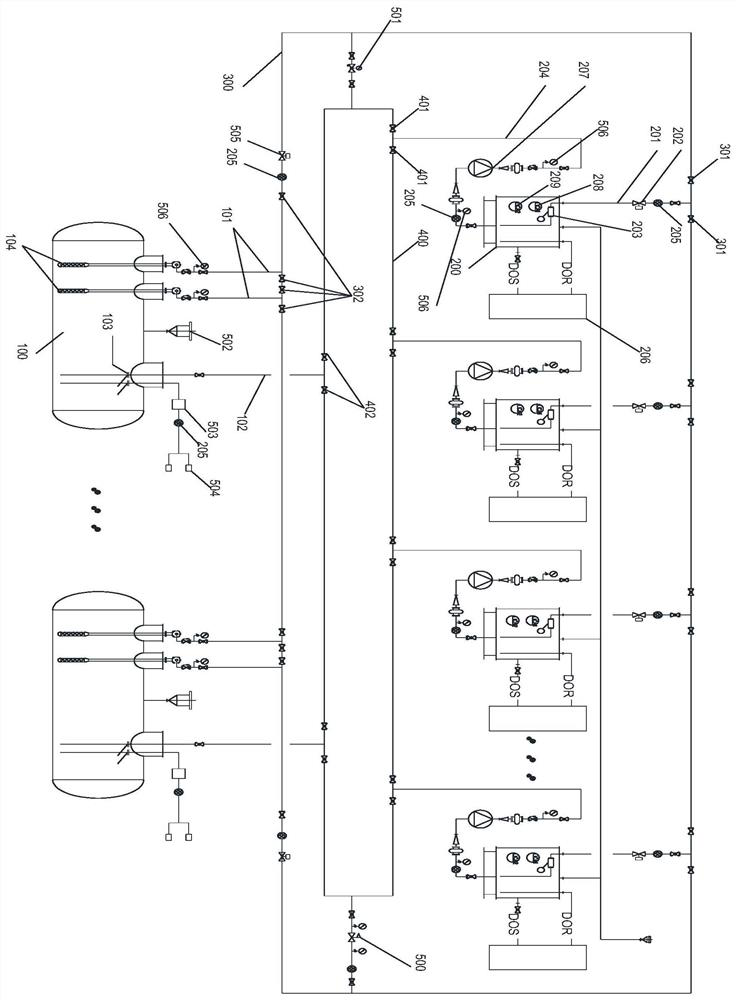

Data Center Diesel Supply System

A diesel supply system, data center technology, applied in packaging, combustion engines, liquid distribution, transportation or transfer devices, etc., can solve problems such as fuel tank overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

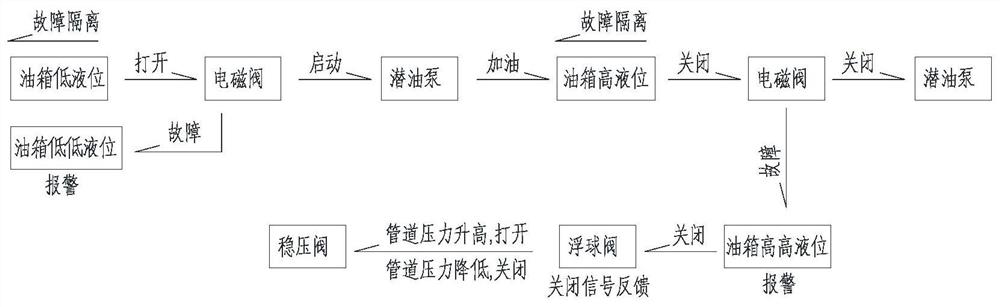

[0055] like figure 2 As shown, the fueling control process of the data center diesel supply system is as follows:

[0056]When the fuel tank is at a low level, the control unit controls the solenoid valve corresponding to the fuel tank to open, starts the submersible pump, and refuels the fuel tank. , the control unit controls the alarm unit to give an alarm. When the fuel tank is filled to the point where the liquid level of the fuel tank is at a high level, the control unit controls the corresponding solenoid valve to close. When the valve fails, the solenoid valve cannot be closed, so that when the liquid level of the fuel tank is at a high level, the alarm unit will give an alarm, and at the same time, the float valve will be automatically closed, and a closing signal will be fed back. When the pressure in the pipeline decreases, the regulator valve closes.

Embodiment 2

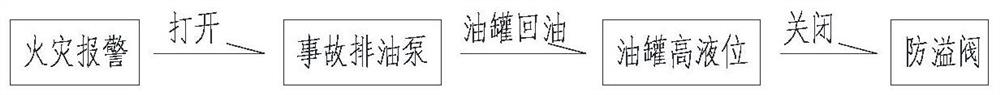

[0058] like image 3 As shown, the fire oil discharge control process of the diesel supply system in the data center is as follows:

[0059] When a fire alarm occurs, the accident oil discharge pump needs to be turned on, so that the diesel oil in the oil tank is returned to the oil tank. If the oil tank is at a high liquid level, the anti-overflow valve should be closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com