A kind of perylene diimide non-fullerene acceptor material and its application

A non-fullerene acceptor and perylene diimide technology, which is applied in the manufacture of electric solid state devices, semiconductor devices, semiconductor/solid state devices, etc., can solve problems such as easy self-polymerization, achieve low production cost, and optimize morphology , Inhibit the effect of charge recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

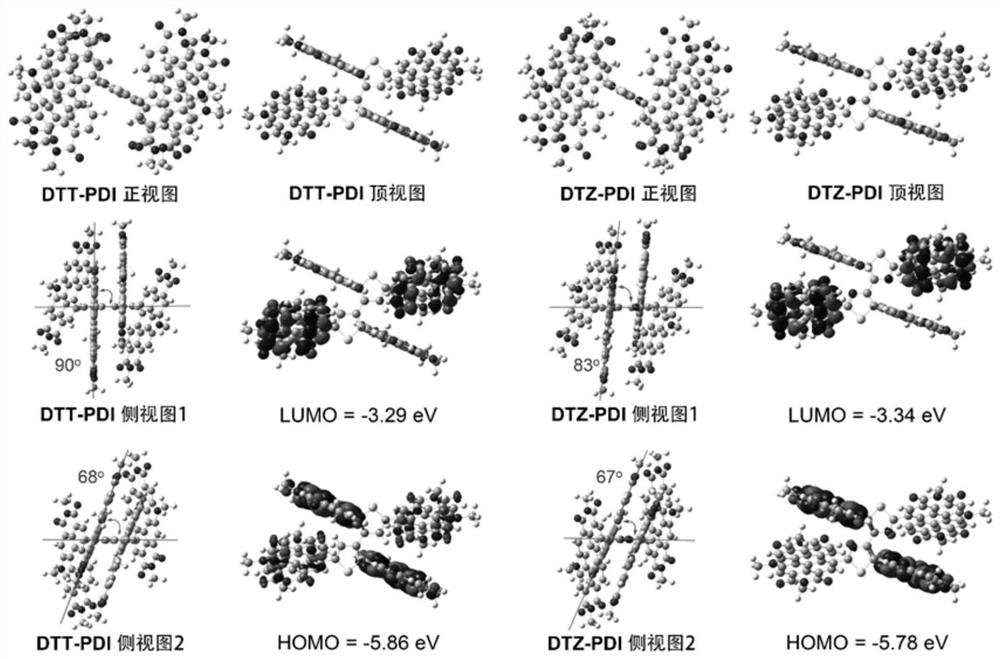

[0024] A kind of perylene diimide non-fullerene acceptor material, its synthetic route is as follows:

[0025]

[0026] The specific synthesis process is as follows: Compound 2 (0.34g, 0.37mmol), intermediate core 1 (0.02g, 0.04mmol) were added to a round bottom flask, and degassed toluene (20mL), 2M potassium carbonate solution (5mL) and ethanol were added (2.5mL) of the mixed solution was repeatedly pumped under an argon atmosphere, then the catalyst tetrakistriphenylphosphine palladium (80mg) was added, and the reaction was protected from light at 120°C for 24 hours; after the reaction was completed, it was cooled to room temperature, Methanol was added to terminate the reaction, the organic solvent was spun out with a rotary evaporator, and the crude product was purified by column chromatography (silica gel; eluent: petroleum ether: dichloromethane = 1:3) to obtain a red solid (0.172 g, yield 30%).

[0027] Proton NMR (400MHz, CDCl3, δ / ppm): 9.11-9.03(t, 6H, ArH), 8.93-...

Embodiment 2

[0031] A kind of perylene diimide non-fullerene acceptor material, its synthetic route is as follows:

[0032]

[0033] The specific synthesis process is as follows: Compound 2 (0.34g, 0.37mmol), intermediate core 3 (0.02g, 0.04mmol) were added to a round bottom flask, degassed toluene (20mL), 2M potassium carbonate solution (5mL) and ethanol (2.5mL) of the mixed solution was repeatedly pumped under an argon atmosphere, and then the catalyst tetrakistriphenylphosphine palladium (80mg) was added to react in the dark at 120°C for 24 hours. After the reaction was completed, it was cooled to room temperature, and methanol was added The reaction was terminated, the solvent was spun out with a rotary evaporator, and the crude product was purified by column chromatography (silica gel; eluent: petroleum ether: dichloromethane = 1:3) to obtain a black-red solid (0.152 g, yield 28%).

[0034] Proton NMR (400MHz, CDCl3, δ / ppm): 9.17-8.89(m, 12H, ArH), 8.69-8.61(m, 2H, ArH), 8.44-8.42(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com