UHPC stone-like building material structure

A technology of building materials and imitation stone, applied in the field of building materials, can solve the problems that cannot be made into large-area slabs, the construction period of slab paving is long, and the imitation stone effect is not real, etc., to achieve strong decorative effect, short construction period and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

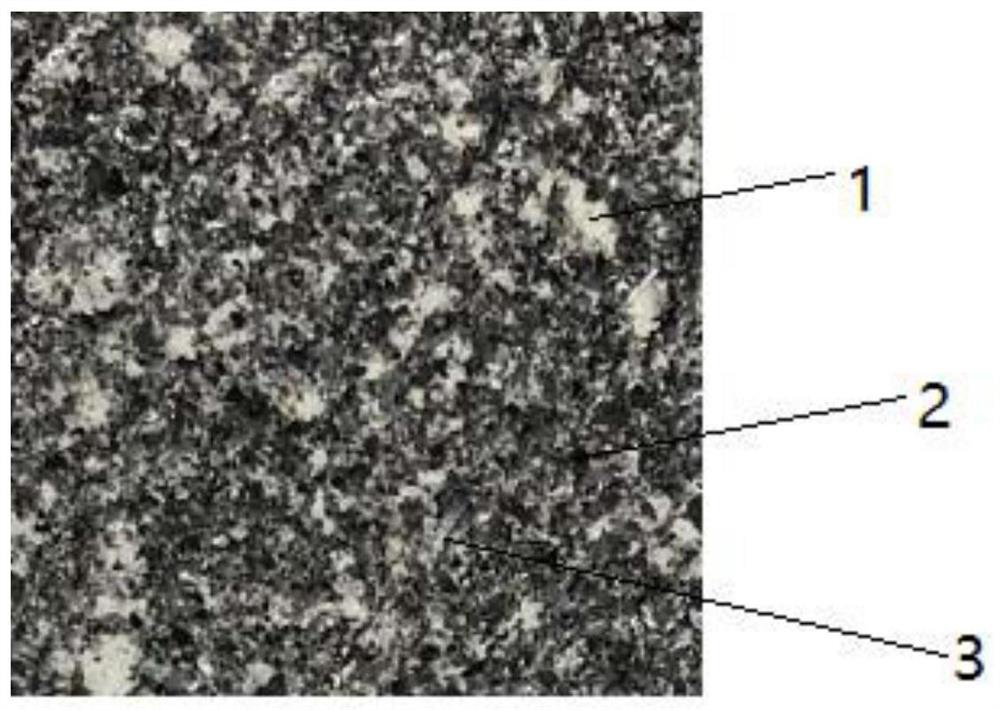

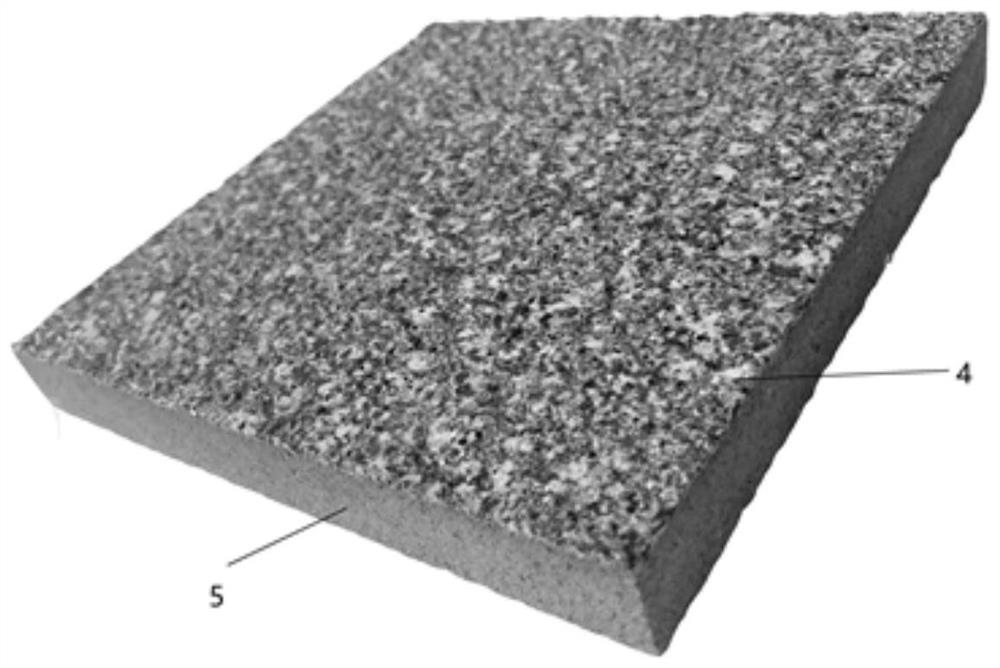

[0044] see figure 1 , 2 , a UHPC imitation stone building material structure, including a surface layer 4 and a base layer 5, the surface layer 4 is located above the base layer 5, the surface layer 4 is formed by spraying and curing the slurry of the first color 1 and the second color 2, and the surface layer 4 There are several bumps of a first color 1 and a second color 2, the bumps are randomly scattered to form an uneven surface.

[0045] The average height difference between the highest point and the lowest point on the surface of the surface layer 4 is 0.3-3mm, and the diameter of the convex spot is 2-30mm, so that the surface layer 4 has a concave-convex feeling and the stone-like effect is realistic.

[0046] The surface layer 4 also has a number of fused stains 3 formed by the cross fusion of the pastes of the first color 1 and the second color 2. The total area of the fused stains 3 accounts for 30% of the total area of the surface layer, so that the surface L...

Embodiment 2

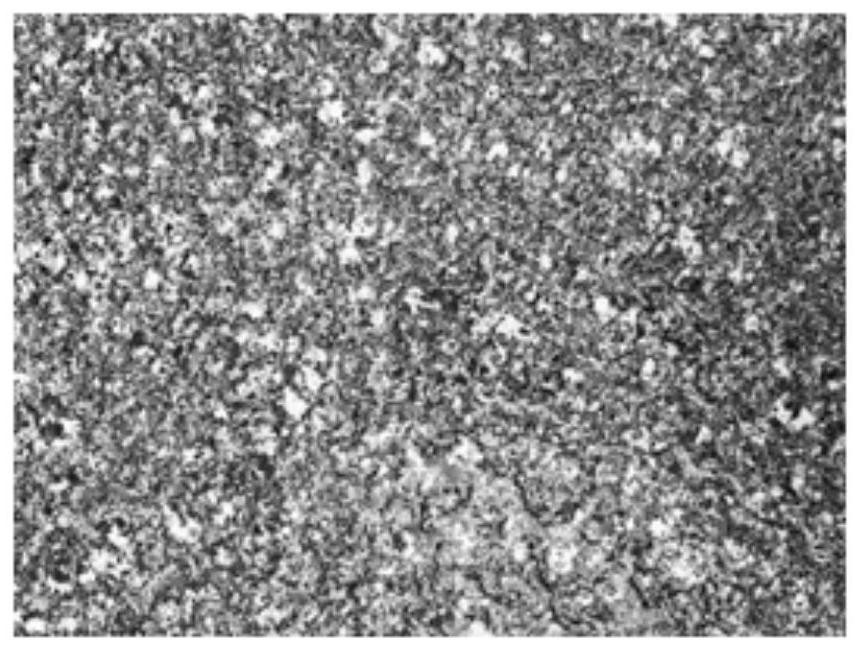

[0069] A UHPC imitation stone building material structure, including a surface layer and a base layer, the surface layer is located above the base layer, and the surface layer is formed by spraying and curing slurry of three colors: the first color, the second color, and the third color. The layer has a number of bumps consistent with the color of the sprayed slurry, and the bumps are randomly scattered to form an uneven surface.

[0070] The average height difference between the highest point and the lowest point on the surface of the surface layer is 0.3-3mm, and the diameter of the convex spot is 2-30mm. The surface layer has a concave-convex feeling, and the stone-like effect is realistic.

[0071] The surface layer also has a number of fused stains formed by the cross fusion of the above three different colored slurries. The total area of the fused stains accounts for 30% of the total area of the surface layer, so that the surface layer presents a stone-like texture. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com