Medical composite ceramic material and preparation method thereof

A technology of composite ceramics and ceramic layers, applied in the field of medical ceramic materials, can solve the problems of unsatisfactory natural tooth color distribution characteristics, single color, etc., and achieve the effect of easy operation, simple preparation process and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides a preparation method of a medical composite ceramic material, the preparation method comprising:

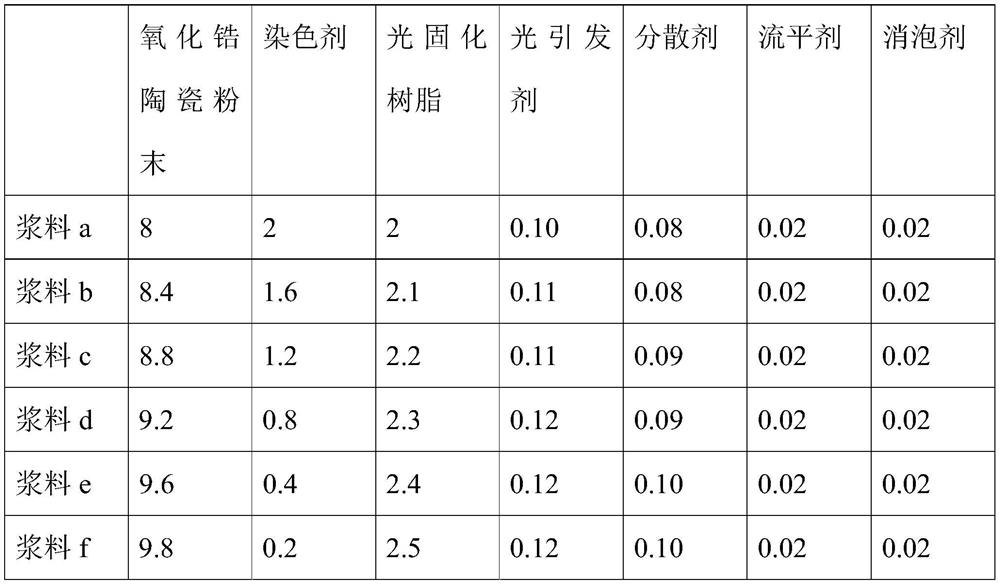

[0074] (1) Prepare 6 parts of slurry with equal mass, which are respectively recorded as slurry a, slurry b, slurry c, slurry d, slurry e and slurry f, and the colors of slurry a to f are from dark to light. Each slurry includes zirconia ceramic powder, dyeing agent, photocurable resin, photoinitiator, dispersant, leveling agent and defoamer, and the quality of each component in each slurry is shown in the following table:

[0075]

[0076] Among them, the particle size of the zirconia ceramic powder is 500nm, the porosity of the zirconia ceramic powder is 25%, and the dyeing agent is Fe 2 o 3 , the photocuring resin is epoxy acrylate, the photoinitiator is 1-hydroxycyclohexyl phenyl ketone, the dispersant is polyacrylic acid derivatives, the leveling agent is polyacrylate, and the defoaming agent is polyether modified polydimethylsiloxane met...

Embodiment 2

[0083] This embodiment provides a preparation method of a medical composite ceramic material, the preparation method comprising:

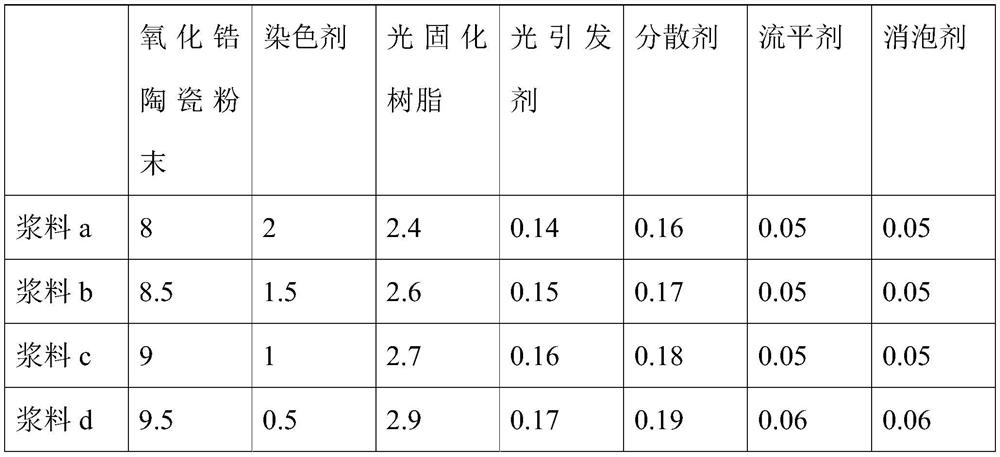

[0084] (1) Prepare four slurries of equal quality, which are respectively recorded as slurry a, slurry b, slurry c and slurry d, and the colors of the slurry a~d range from dark to light. Each slurry includes zirconia ceramic powder, dyeing agent, photocurable resin, photoinitiator, dispersant, leveling agent and defoamer, and the quality of each component in each slurry is shown in the following table:

[0085]

[0086] The particle size of the zirconia ceramic powder is 20000nm, the porosity of the zirconia ceramic powder is 27%, and the dyeing agent is Pr 2 o 3 , the light-curing resin is polyurethane acrylate, the photoinitiator is benzoin dimethyl ether, the dispersant includes polycarboxylate, the leveling agent is polyacrylate, and the defoamer is polyether-modified polydimethylsiloxane;

[0087] (2) The raw materials weighed in proport...

Embodiment 3

[0093] This embodiment provides a preparation method of a medical composite ceramic material, the preparation method comprising:

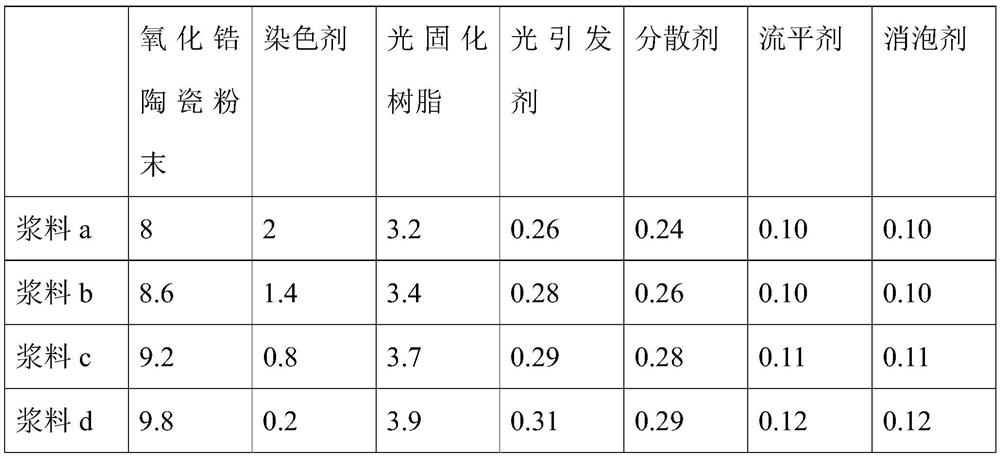

[0094] (1) Prepare 4 slurries of equal mass, which are respectively recorded as slurries a, slurries b, slurries c and slurries d, and the colors of slurries a~d range from dark to light. Each slurry includes zirconia ceramic powder, dyeing agent, photocurable resin, photoinitiator, dispersant, leveling agent and defoamer, and the quality of each component in each slurry is shown in the following table:

[0095]

[0096] The particle size of zirconia ceramic powder is 30000nm, the porosity of zirconia ceramic powder is 30%, and the dyeing agent is Er 2 o 3 The photocurable resin is polyester acrylate, the photoinitiator is benzophenone, the dispersant is polyvinylpyrrolidone, the leveling agent is polyacrylate, and the defoaming agent is polyether modified polydimethylsiloxane;

[0097] (2) The raw materials weighed in proportion are ready for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com