Wind-resistant and waterproof step steel plate roof structure

A technology of stepped board and steel plate, applied in the direction of roof, roof using flat/curved board, roof covering layer, etc., can solve the problems of inconvenient installation, poor roof aesthetics, etc., and achieve cost saving, appearance and other performance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

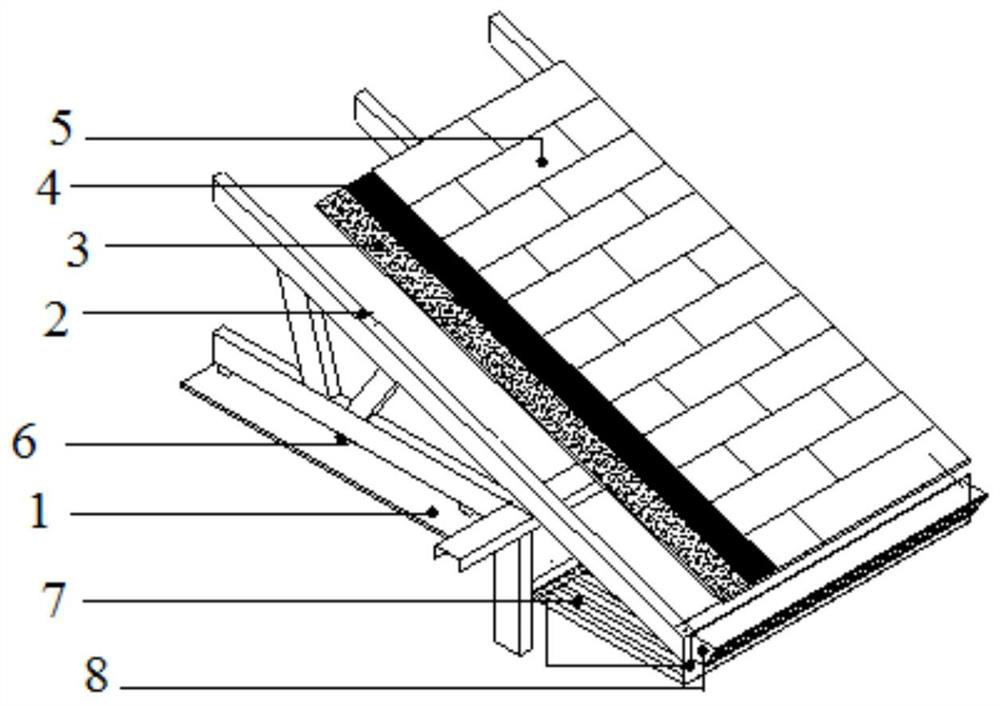

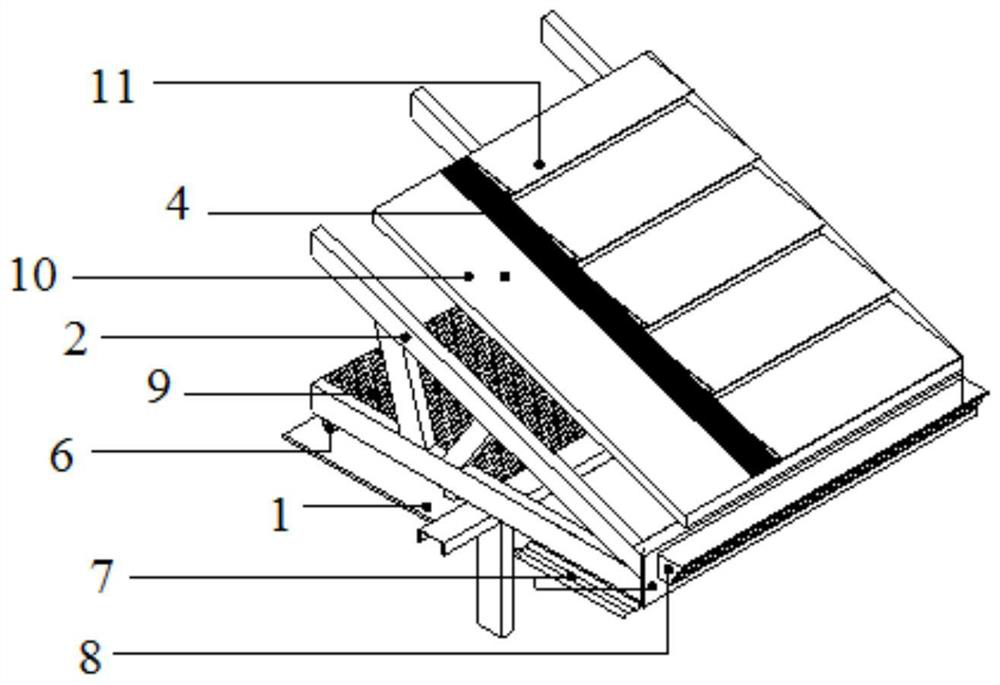

[0027] A wind-resistant and waterproof stepped steel plate roof structure, its structure see figure 2 As shown, it includes a suspended ceiling gypsum board 1, a light steel roof truss 2, and a composite board 10 with a slope laid on the light steel roof truss 2. The composite board 10 is also provided with stepped boards 11 inserted in sequence along the direction of its slope. The upper and lower ends of the step plate 11 respectively form a female end 14 and a male end 13. When the step plate 11 is paved, the male end 13 of the upper step plate 11 presses the female end 14 of the lower step plate 11. , and fastened and plugged with each other, and the buckled and plugged parts of the male buckle end 13 and the female buckle end 14 are also connected to the composite board 10 through a hidden detachable structure.

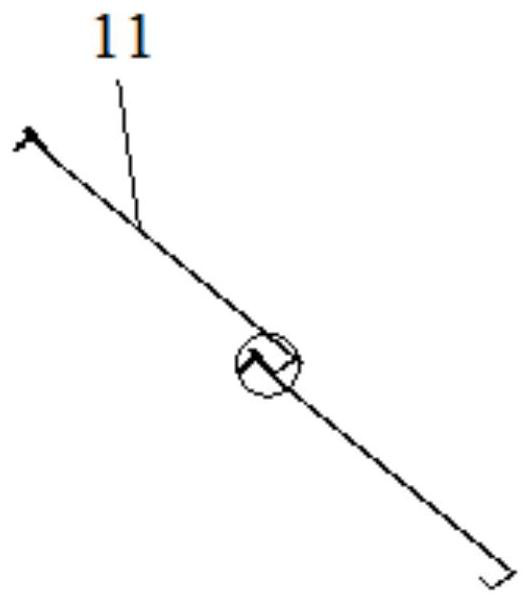

[0028] See image 3 with Figure 4 As shown, the upper end of the stepped plate 11 is bent upwards and then bent inwards to form a U-shaped structure, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com