Automatic detection device for trenchless reaming hole bottom slurry pressure and drill bit torque

An automatic detection device and non-excavation technology, which is applied to the automatic control system of drilling, measurement, earthwork drilling and production, etc. It can solve the problems that the surface sensors and instruments cannot accurately grasp the real working conditions in the hole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

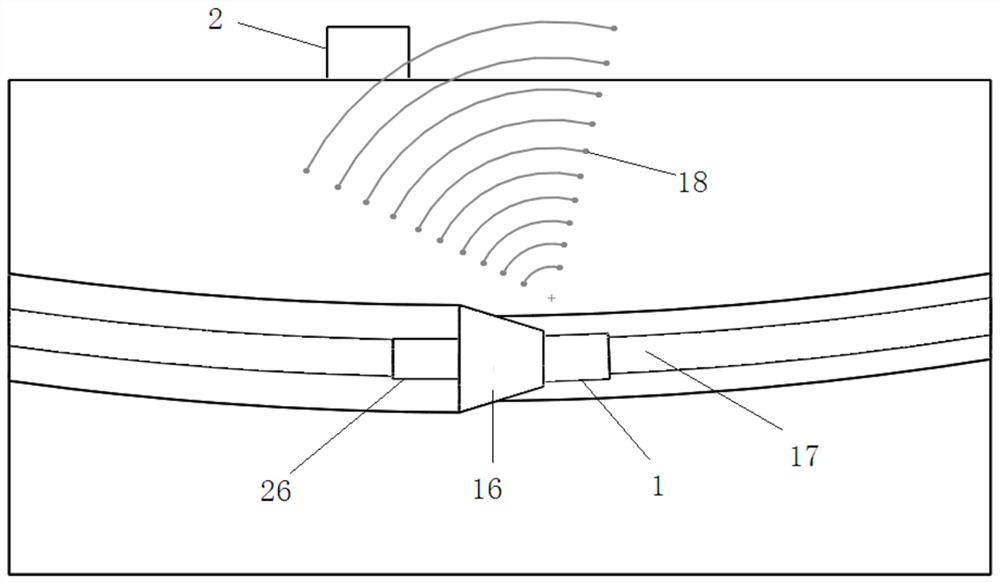

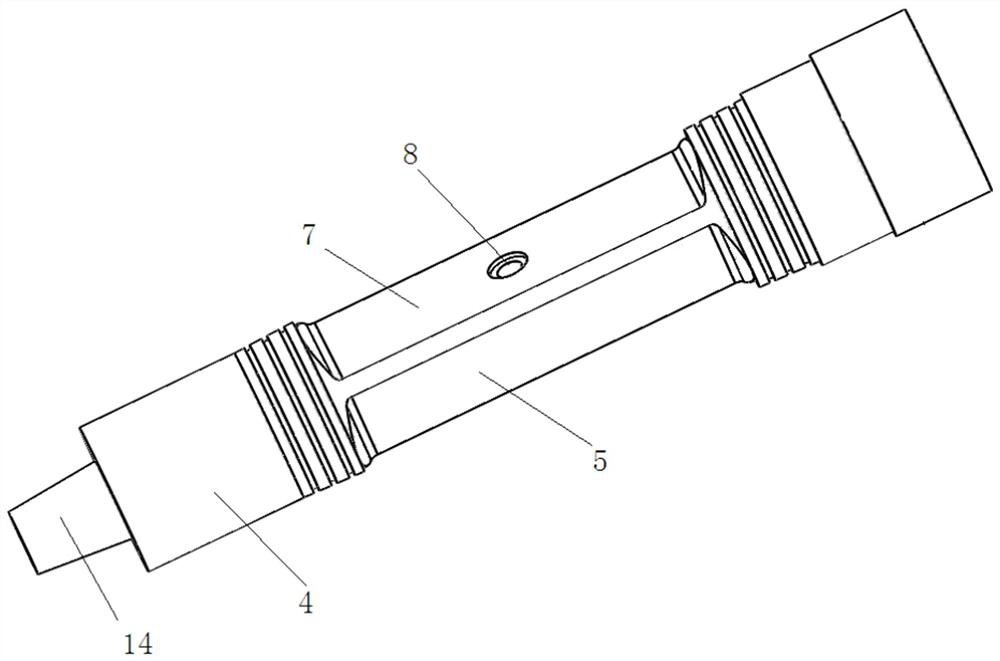

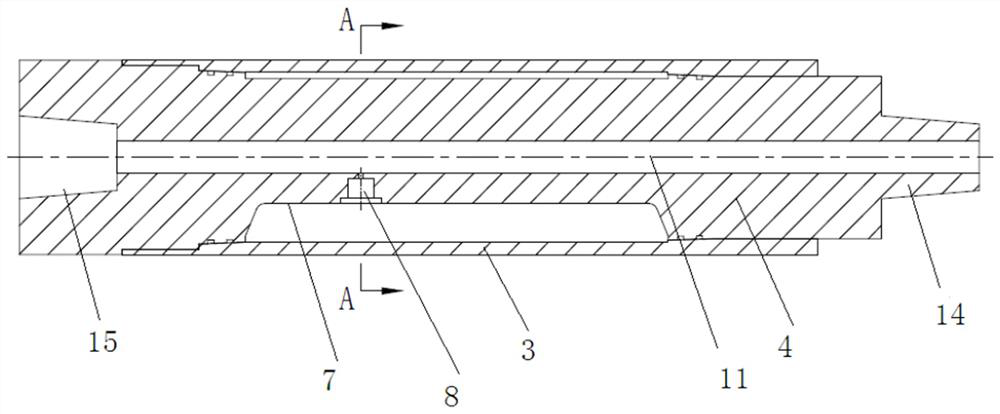

[0012] In the figure, an automatic detection device for the mud pressure at the bottom of a trenchless reaming hole and the torque of a drill bit is characterized in that it is composed of an underground sub-section 1 and surface receiving and processing equipment 2, the underground sub-section is a cylinder 3 structure, and the cylinder 3 inside is a cylinder 4, the two ends of the cylinder are attached to the inner wall of the cylinder, and the middle part of the cylinder is a triangular pyramid 5, and an arc surface 6 is milled on the two corners of the triangular pyramid, and the There are strain gauges on the surface, and a pressure sensor 8 is installed on the cone surface 7 between the two edges with strain gauges, and a circuit board 9 and a power supply 10 are respectively installed at the gap between the other two cone surfaces and the cylinder. , a through hole 11 is opened on the central axis of the triangular pyramid. The strain gauges pasted on the arc surfaces o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com