Ultrasonic welding construction method for large-diameter PE natural gas pipelines

A natural gas pipeline, ultrasonic welding technology, applied in the direction of pipeline connection layout, pipe/pipe joints/pipe fittings, tubular objects, etc., can solve the problems of complicated operation process and welding technology, inoperable operation mode, low operation efficiency, etc. The effect of prolonging the construction operation season, improving operation efficiency and increasing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

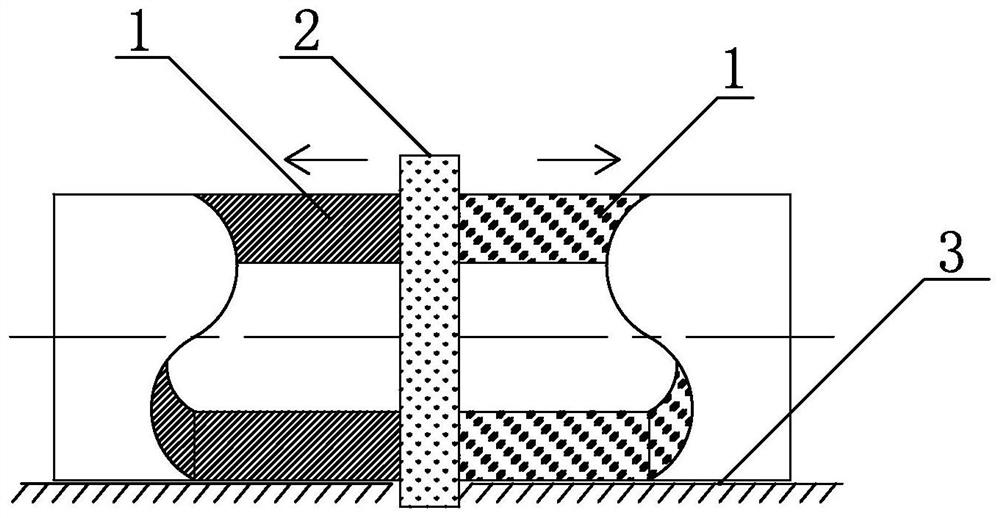

[0052] The large diameter referred to in the present invention refers to the PE natural gas pipeline above DN100, and the ultrasonic welding construction method of the large diameter PE natural gas pipeline of the present invention comprises the following steps:

[0053] S10, perform section cleaning and chamfering operations on the two sections of PE natural gas pipelines 1 that need to be connected;

[0054] S20, immerse the two sections of PE natural gas pipeline 1 in hot water at 95-100°C for 3-5 minutes, so that the two sections of PE natural gas pipeline 1 appear softened, but the PE natural gas pipeline 1 cannot be obviously deformed;

[0055] S30, use a clean water-absorbing material to wipe off the water droplets on the surface of the two-section PE natural gas pipeline 1;

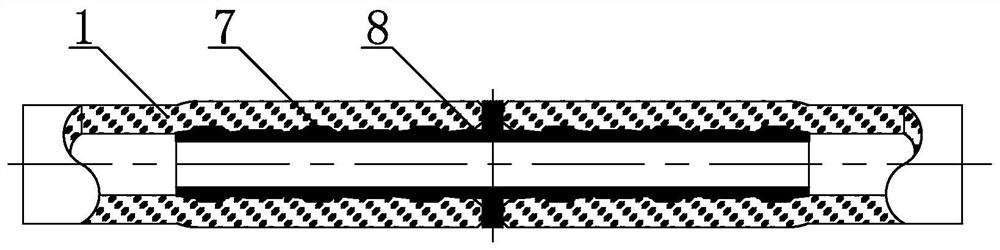

[0056] S40, if the thickness of PE natural gas pipeline 1 is not greater than 6.3mm, such as image 3 As shown, the sealing support 8 is aligned with the inner surfaces of the two PE natural gas ...

Embodiment 2

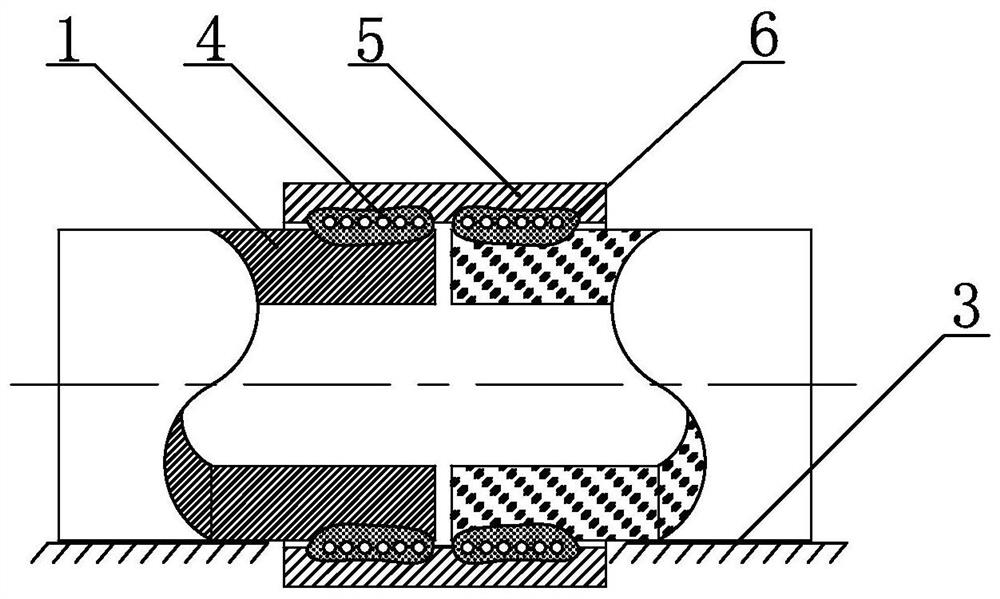

[0067] The difference between this embodiment and Embodiment 1 lies in step S40 and step S50, such as Figure 8 As shown, when the thickness of the PE natural gas pipeline 1 is greater than 6.3 mm, no preprocessing of the PE natural gas pipeline 1 is required in this embodiment.

[0068] Specific steps include:

[0069] S10, perform section cleaning and chamfering operations on the two sections of PE natural gas pipelines 1 that need to be connected;

[0070] S20, immerse the two sections of PE natural gas pipeline 1 in hot water at 95-100°C for 3-5 minutes, so that the two sections of PE natural gas pipeline 1 appear softened, but the PE natural gas pipeline 1 cannot be obviously deformed;

[0071] S30, use a clean water-absorbing material to wipe off the water droplets on the surface of the two-section PE natural gas pipeline 1;

[0072] S40, align the sealing support 8 with the inner surfaces of the two PE natural gas pipelines 1, and quickly push the PE natural gas pipel...

Embodiment 3

[0078] The difference between this embodiment and Embodiment 1 lies in step S50, such as Figure 10 As shown, when the thickness of the PE natural gas pipeline 1 is greater than 6.3mm, the PE natural gas pipeline 1 is preprocessed, and then ultrasonic welding bands 7 are added to the two sections of the pipe wall with different thicknesses.

[0079] Specific steps include:

[0080] S10, perform section cleaning and chamfering operations on the two sections of PE natural gas pipelines 1 that need to be connected;

[0081] S20, immerse the two sections of PE natural gas pipeline 1 in hot water at 95-100°C for 3-5 minutes, so that the two sections of PE natural gas pipeline 1 appear softened, but the PE natural gas pipeline 1 cannot be obviously deformed;

[0082] S30, use a clean water-absorbing material to wipe off the water droplets on the surface of the two-section PE natural gas pipeline 1;

[0083] S40, if the thickness of the PE natural gas pipeline 1 is not greater than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com