A fuel cell thermal management system and method for a passenger car

A thermal management system and fuel cell technology, applied in the fields of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of slow fuel cell cold start speed, large flow resistance of PTC circuit, cold start failure, etc. The effect of avoiding violent temperature fluctuations, prolonging service life and reducing working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that this embodiment is only used to illustrate the present invention, but is not limited to this embodiment.

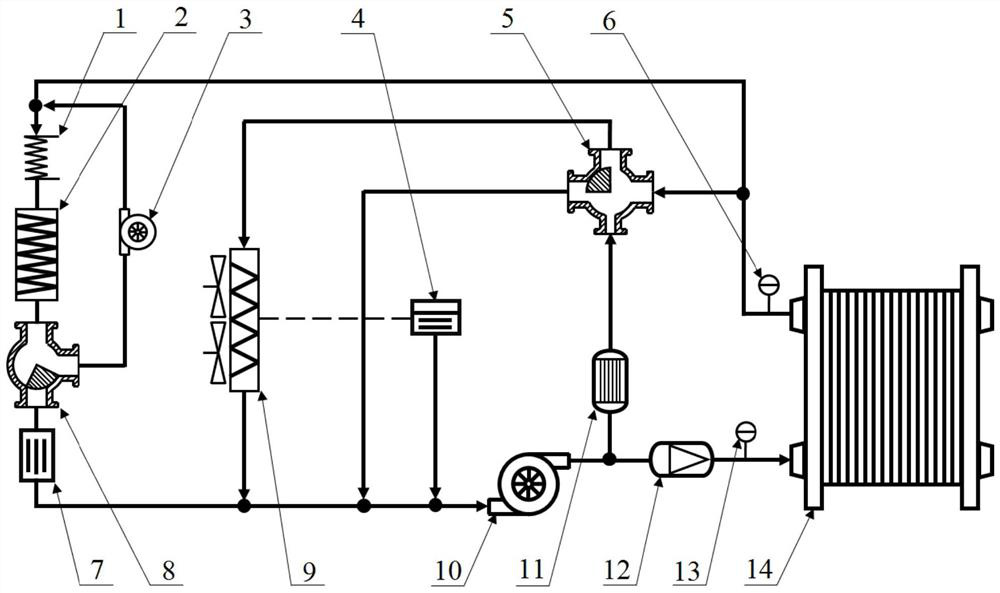

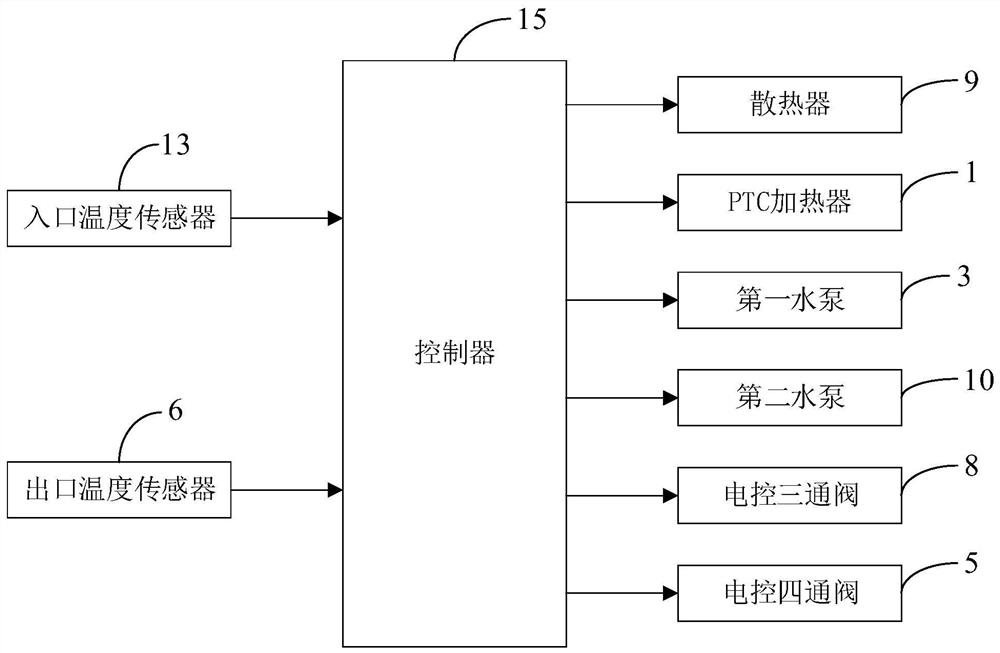

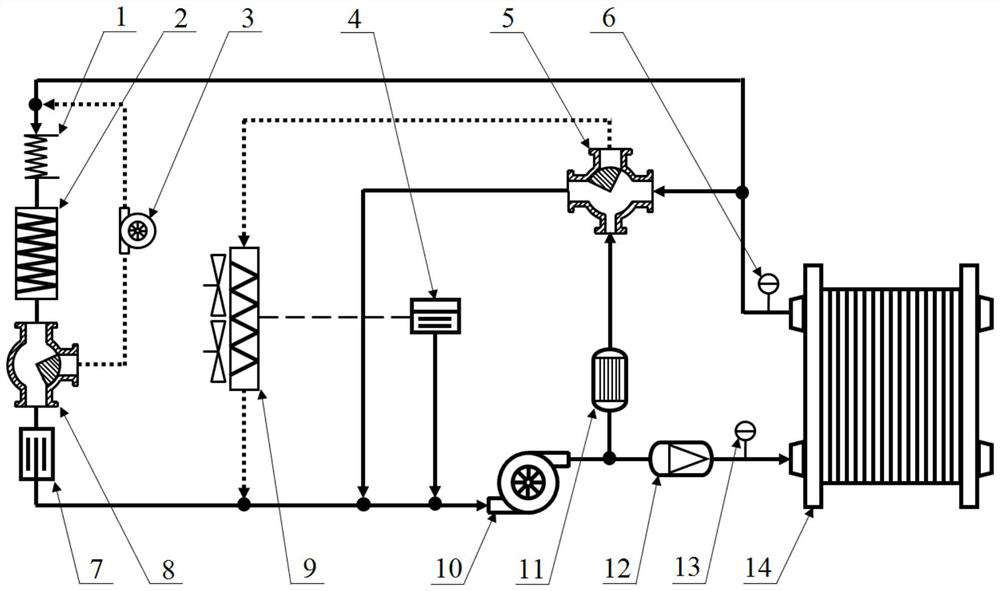

[0027] Such as Figure 1 to Figure 7 The fuel cell thermal management system shown in the passenger car includes a controller 15, a fuel cell 14, an inlet temperature sensor 13, an outlet temperature sensor 6, an electronically controlled four-way valve 5, a PTC heater 1, a warm air core 2, a A water pump 3, an electronically controlled three-way valve 8, a deionizer 7, a radiator 9, a second water pump 10, an intercooler 11, a water tank 4 and a filter 12. The electronically controlled four-way valve 5 has a four-way valve body 50, a four-way valve spool 51, a first normally open inlet 54 of the four-way valve, a second normally open inlet 55 of the four-way valve, and a first controllable outlet 52 of the four-way valve , The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com