Spine motion segment in-vivo loading device

A technology of loading device and driving device, which is applied in sports accessories, gymnastics equipment, medical science, etc., can solve the problems such as the specific process is not clear, and achieve the effect of light weight and compact structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

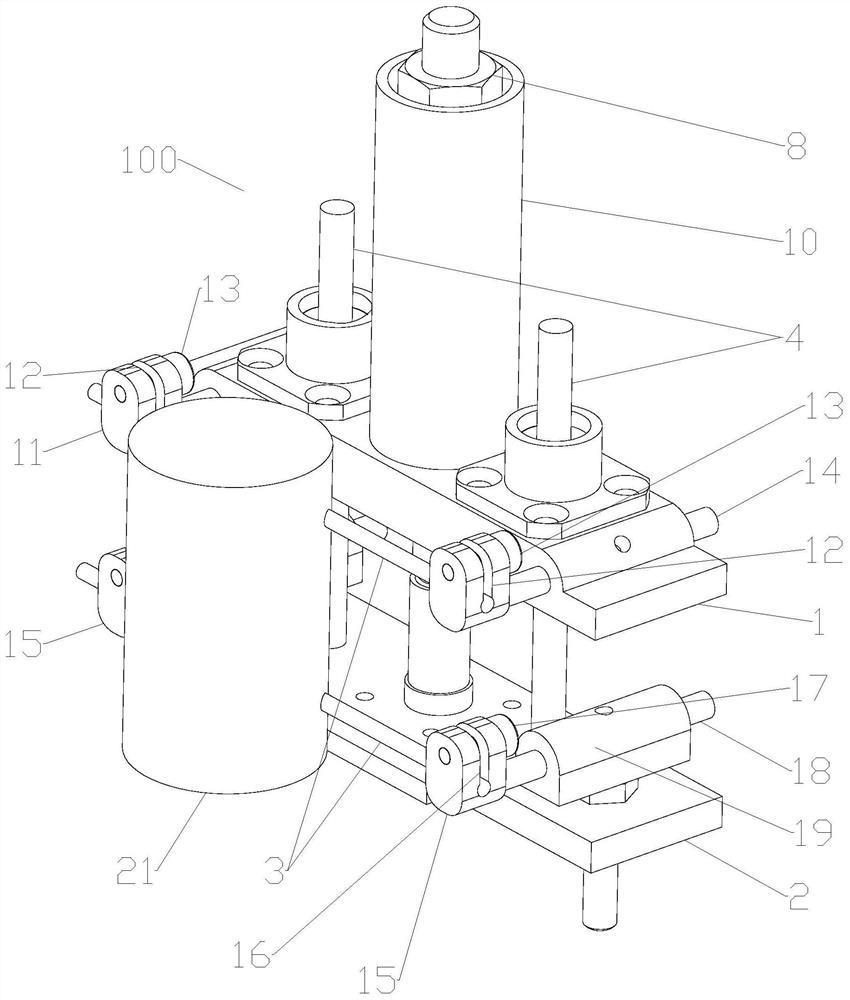

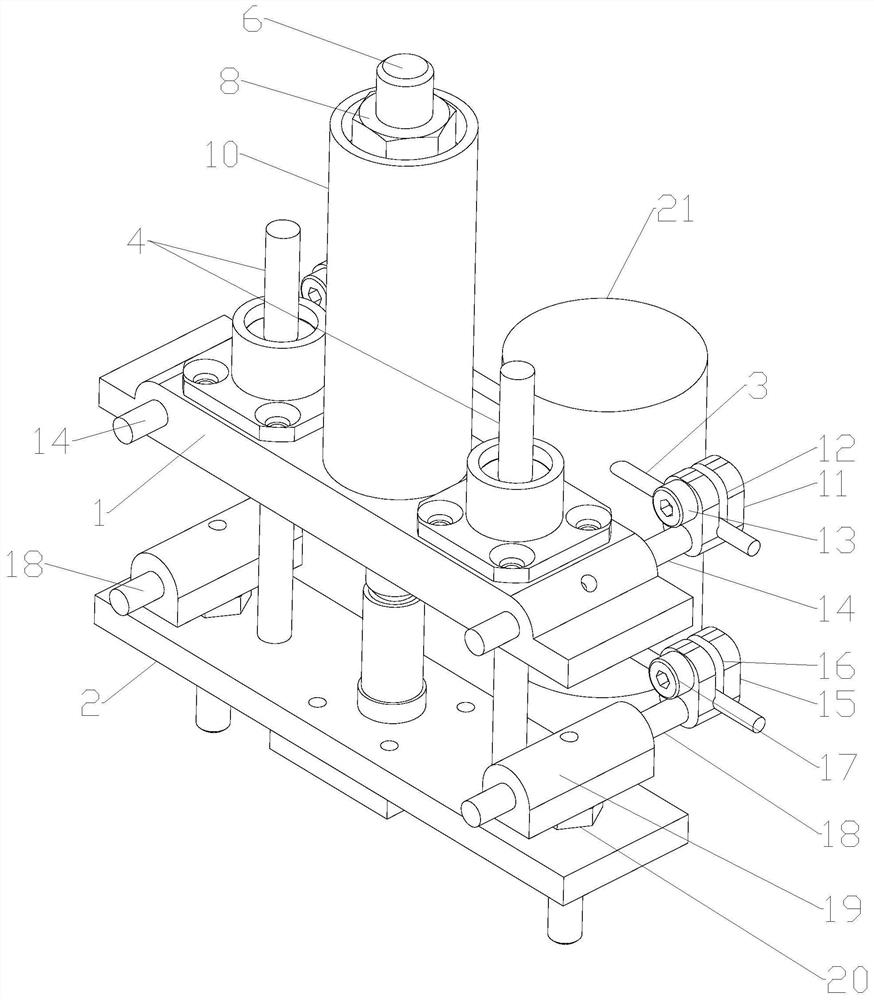

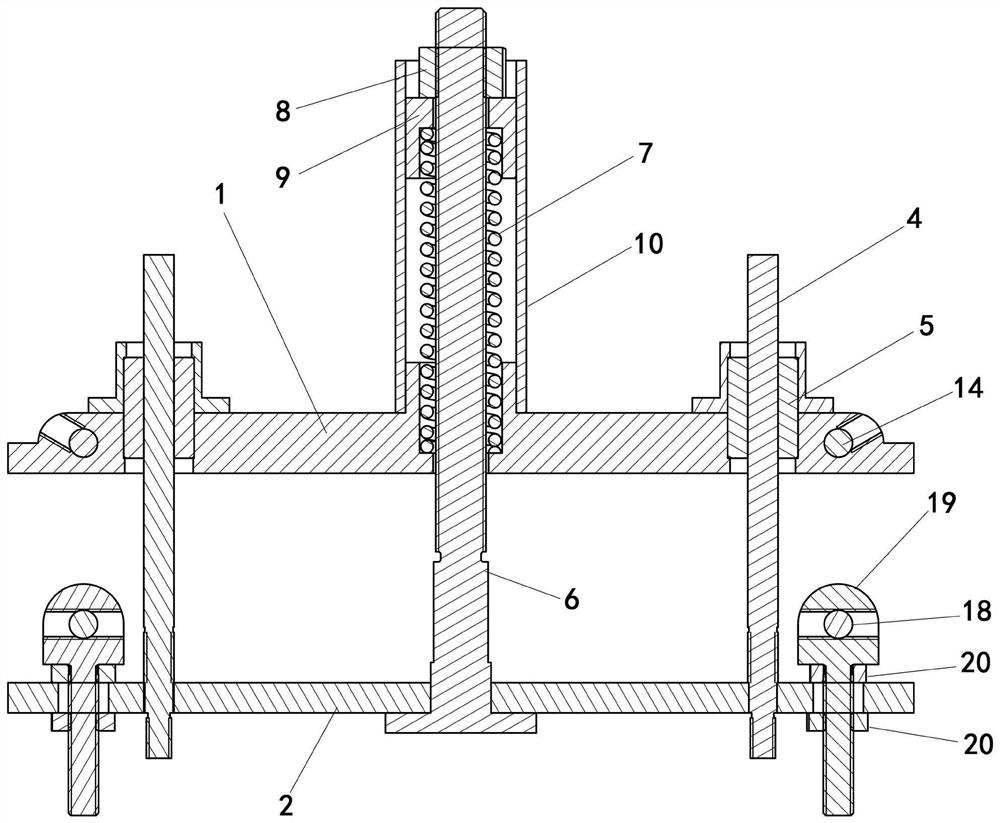

[0026] Such as Figure 1-3 As shown, the spinal motion segment in-body loading device 100 provided by the embodiment of the present invention includes a first loading board 1 , a second loading board 2 , a sliding mechanism and a driving device. The first loading plate 1 is provided with a first mounting base 11 for installing the Kirschner wires 3 , and the second loading plate 2 is provided with a second mounting base 15 for installing the Kirschner wires 3 . The first loading plate 1 and the second loading plate 2 are slidably connected through a sliding mechanism, and the driving device is used to drive the first loading plate 1 and the second loading plate 2 to approach each other.

[0027] During use, the Kirschner wire 3 on the first mount 11 is passed through the upper segment of the spine 21, the Kirschner wire 3 on the second mount 15 is passed through the lower segment of the spine 21, and the first mount is driven by the driving device. The mounting seat 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com