Agricultural soil treatment and remediation device

A soil and agricultural technology, applied in the agricultural field, can solve problems such as uneven soil remediation, reduce soil remediation efficiency, etc., and achieve the effect of improving remediation efficiency and avoiding unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] like figure 1 As shown, an agricultural soil treatment and repair device includes a vehicle frame 1, a walking wheel 2, a soil turning mechanism 3, a first suspension frame 4, a second suspension frame 5, a conveying and mixing mechanism 6 and a feeding mechanism 7, and the vehicle frame Both sides of the left side of the left part of 1 are all rotatably equipped with traveling wheels 2, the right side of the vehicle frame 1 is provided with a soil turning mechanism 3, the middle part of the soil turning mechanism 3 is connected with a first suspension frame 4, and the first suspension frame 4 front and back two The soil-turning mechanism 3 on the side is provided with a second suspension frame 5, and the vehicle frame 1 on the left side of the soil-turning mechanism 3 is equipped with a conveying and stirring mechanism 6, and the conveying and stirring mechanism 6 is connected with the soil-turning mechanism 3, and the vehicle frame 1 is equipped with a feeding mechanis...

Embodiment 2

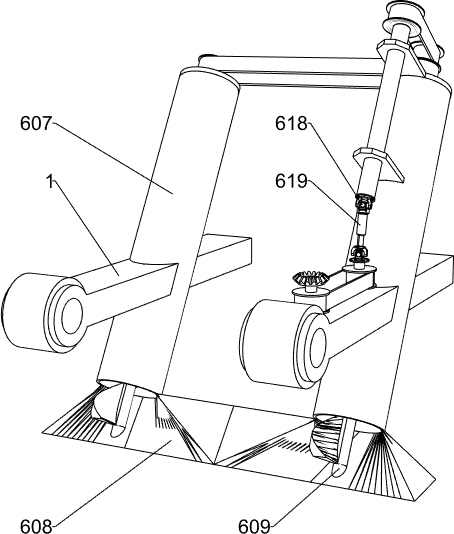

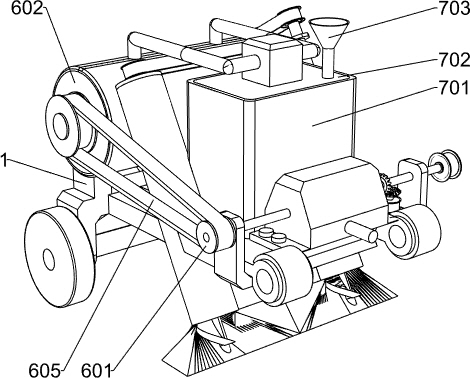

[0034] like Figure 2-6 As shown, on the basis of Embodiment 1, the conveying and stirring mechanism 6 includes a third pulley 601, a stirring drum 602, a stirring blade 603, a fourth pulley 604, a second belt 605, a blanking frame 606, a feeding Barrel 607, pusher frame 608, screw feed frame 609, fifth pulley 610 and third belt 611, the third pulley 601 is connected to the front side of the first rotating shaft 305 on the front side, and the top left side of the vehicle frame 1 is installed with Stirring drum 602, stirring blade 603 is installed rotatably in the stirring drum 602, the fourth pulley 604 is installed on the front side of the rotating shaft of stirring blade 603, and the second belt 605 is wound between the fourth pulley 604 and the third pulley 601 , the lower part of the mixing drum 602 is embedded with a blanking frame 606, the front and rear sides of the vehicle frame 1 on the right side of the mixing drum 602 are embedded with upper feeding drums 607, and t...

Embodiment 3

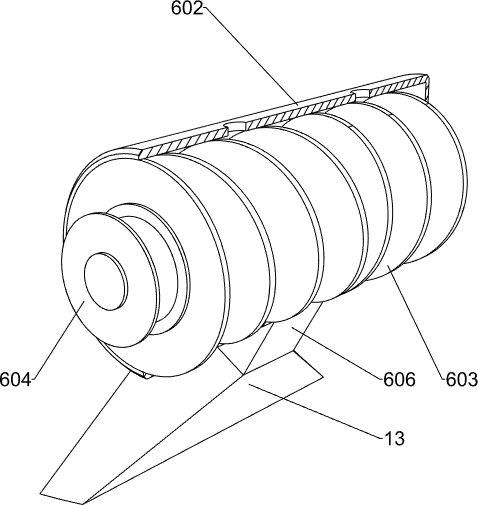

[0041] like Figure 8 As shown, on the basis of the second embodiment, a discharge frame 13 and a partition 14 are also included. The bottom of the discharge frame 606 is equipped with a discharge frame 13, and the front and rear sides of the inner wall of the discharge frame 13 are installed obliquely. There are partitions 14 .

[0042] After the repaired and processed soil in the mixing drum 602 falls in the blanking frame 606, the soil in the blanking frame 606 falls downwards in the discharging frame 13. The plates 14 are all inclined, and the soil in the discharge frame 13 can be evenly scattered in the field through the dividing plate 14, which can avoid repairing the processed soil and pile up when falling in the field.

[0043] like figure 1 and Figure 9 As shown, it also includes a connecting frame 8, a third rotating shaft 9, a torsion spring 10, a connecting plate 11 and a pressure roller 12, and the front and rear sides of the left side wall of the vehicle frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com