A kind of mixing method of natural rubber using farrel K6 internal mixer

A technology of natural rubber and internal mixer, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of inability to process, low systematic efficiency, etc., and achieve the effect of reducing the number of commissioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Equipment: Farrel K6 secret refining machine

[0027] Natural rubber: A rubber SCR5

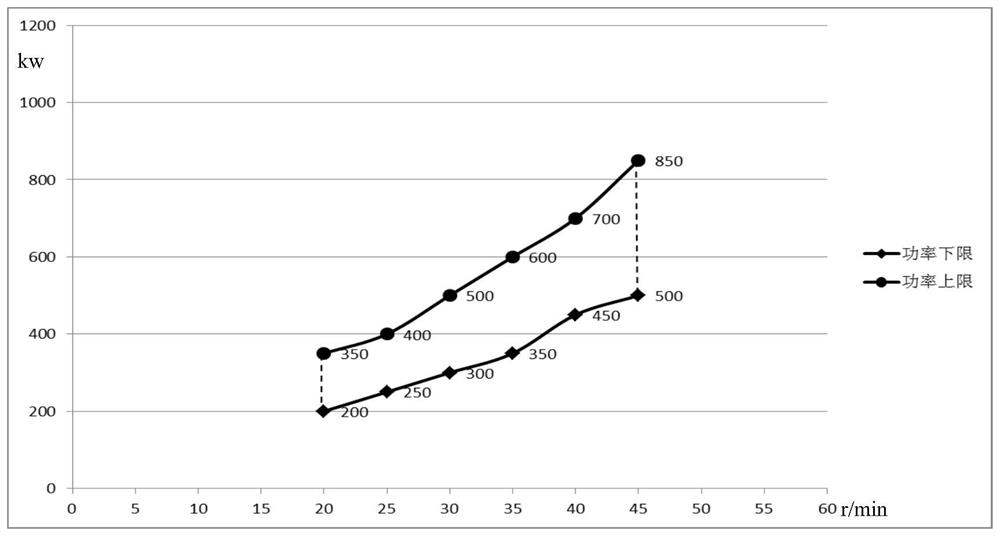

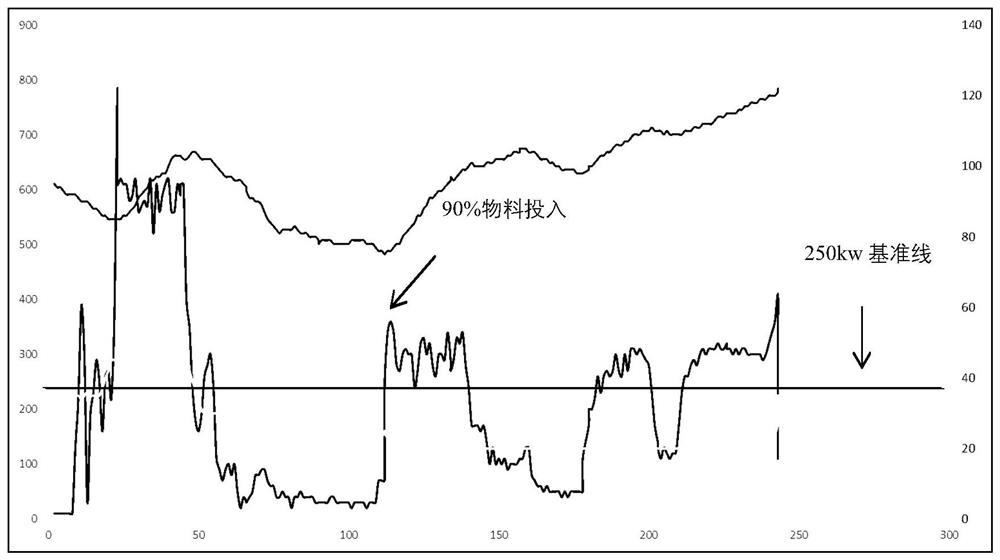

[0028] Analyze the composition of glue formula, select the fill coefficient and mixed process according to previous experience, and perform the first trial mixing. figure 2 Show.

[0029] like figure 2 It is shown in the schematic diagram of various curves with a reasonable curve of the A rubber SCR5 mixed process. When 90 % of the materials are invested, the power values of the curves of each section of the curves are in a reasonable range; all the power curves are also above the 250kW reference line; the mixed time of each section is in the reasonable range; Turned to calm and slow down, indicating that the rubber has reached the "plasticization" stage. Based on the above aspects, this mixed process is determined to be qualified. Through this system, the processing process of the process of process has reduced the number of debugging times to a large extent, and the rationality of the ...

Embodiment 2

[0031] Equipment: Farrel K6 secret refining machine

[0032] Natural rubber: B rubber SCR20

[0033] Specific operation steps:

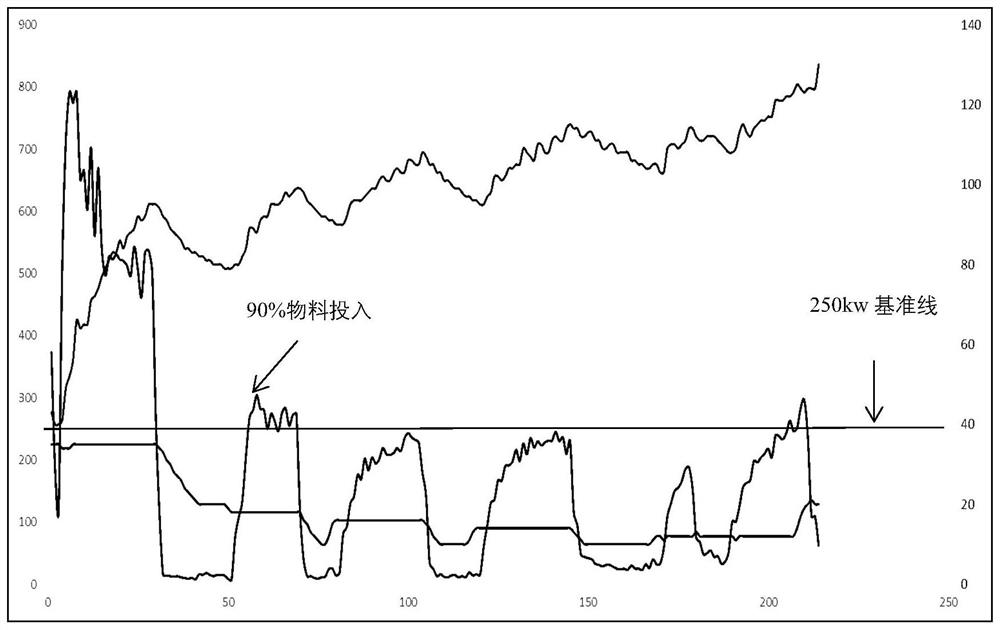

[0034] (1) Analyze the composition of the glue formula, select the filling coefficient and mixed process according to previous experience, and perform the first trial mixing, the power, speed, and temperature curve of the mix image 3 Show;

[0035] (2) Analysis image 3 Send the following information: Although the first section of the raw glue plastic section is only invested by a small part of the material, the materials in the secret refining machine are far from 90 %, but at the speed of 35R / min The rational range of 350kW ~ 600KW at this speed; the power of the last section reached 200kW to 300kW at a speed of 15R / min, and the reasonable power range under 20R / min was 200kW ~ 350kW; After that, the curve segment of more than 1 / 2 is below the 250kW reference line. Based on the above, it is determined that the coordination of rubber production is too lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com