Material spreading device for artificial stone manufacturing

A technology of artificial stone and dredging, which is applied in the field of spreading devices for artificial stone manufacturing, can solve problems such as single pattern of artificial stone, and achieve the effect of avoiding single pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

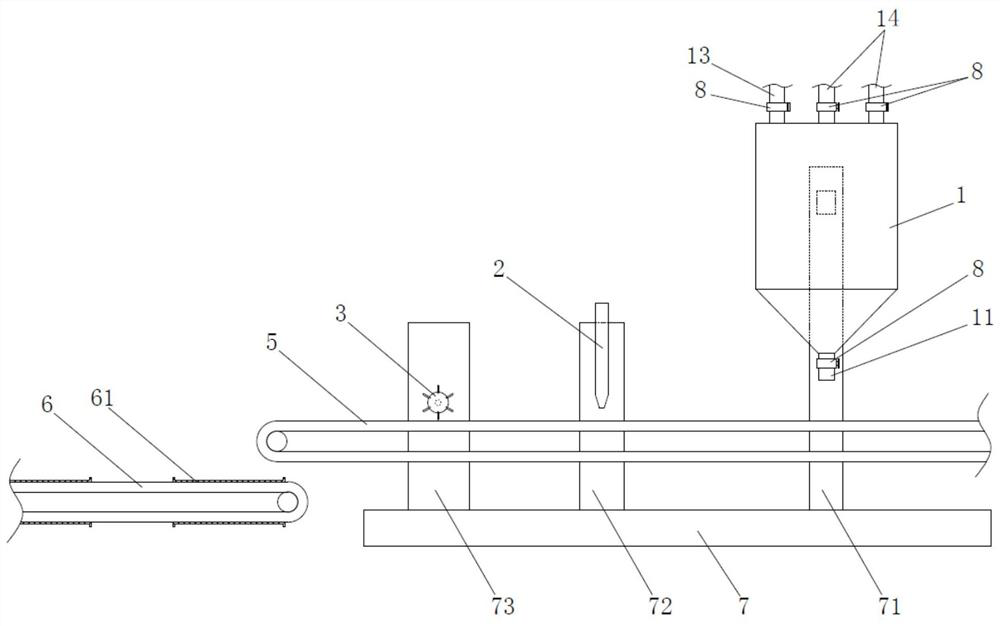

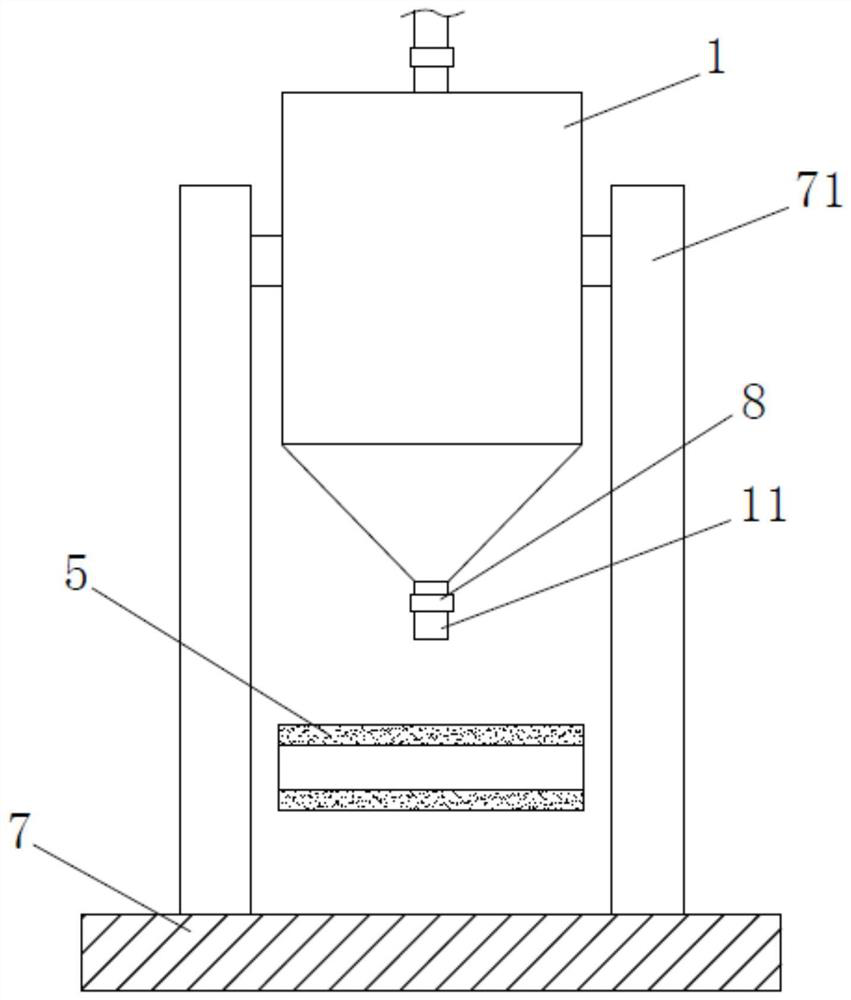

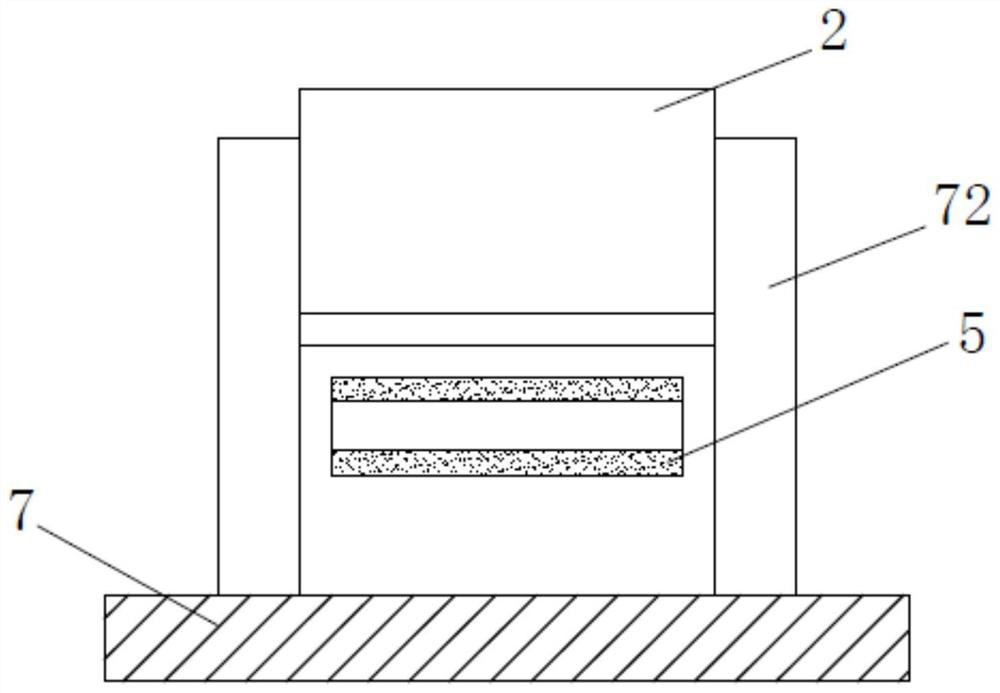

[0036] The specific embodiment of the present invention is as Figure 1-5 As shown, a spreading device for artificial stone manufacturing includes a horizontally arranged conveyor belt 5, and a storage tank 1, a scraper 2, and a sparse roller 3 are sequentially arranged above the conveyor belt 5 along its feeding direction. The lower end of the storage tank 1 is provided with a discharge pipe 11 . The sparser roller 3 is arranged horizontally and its extension direction is perpendicular to the feeding direction of the conveyor belt 5. The roller surface of the sparser roller 3 is inserted with a plurality of sparser tooth plates 4 arranged around its axis. One end of the sparse material roller 3 is connected with the drive motor 74 transmission. A transfer belt 6 is also arranged horizontally below the discharge end of the conveyor belt 5 . In this embodiment, the belt surfaces of the conveyor belt 5 and the transfer belt 6 are provided with anti-adhesive layers.

[0037] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com