High-precision automatic paperboard mounting machine and control method

A paper laminating machine, high-precision technology, applied in mechanical processing/deformation, devices for coating liquid on the surface, coatings, etc., can solve the problems of long lamination interval, poor paper length adaptability, etc., to avoid stress Non-uniform, uniform force, avoid tilt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

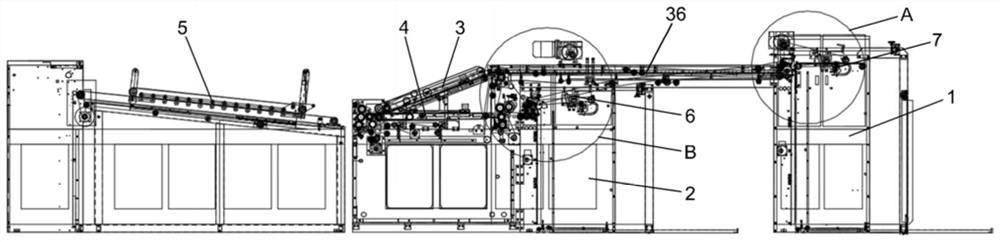

[0046] refer to figure 1 As shown, a high-precision automatic cardboard laminating machine includes a facial paper feeding frame 1, a cardboard feeding frame 2, a facial tissue conveying mechanism 3, a jamming conveying mechanism 4, a pressing mechanism 5, a facial tissue fly Reach head 6, jam feeder head 7, first servo drive device, second servo drive device, alignment drive device, conveying control system, frame.

[0047] Face paper feeding frame 1, jammed paper feeding frame 2, jammed paper conveying mechanism 4, pressing device 5 are arranged in sequence along the paper conveying direction, the first, second servo drive device and alignment drive device are respectively electrically controlled with the conveying control system connect.

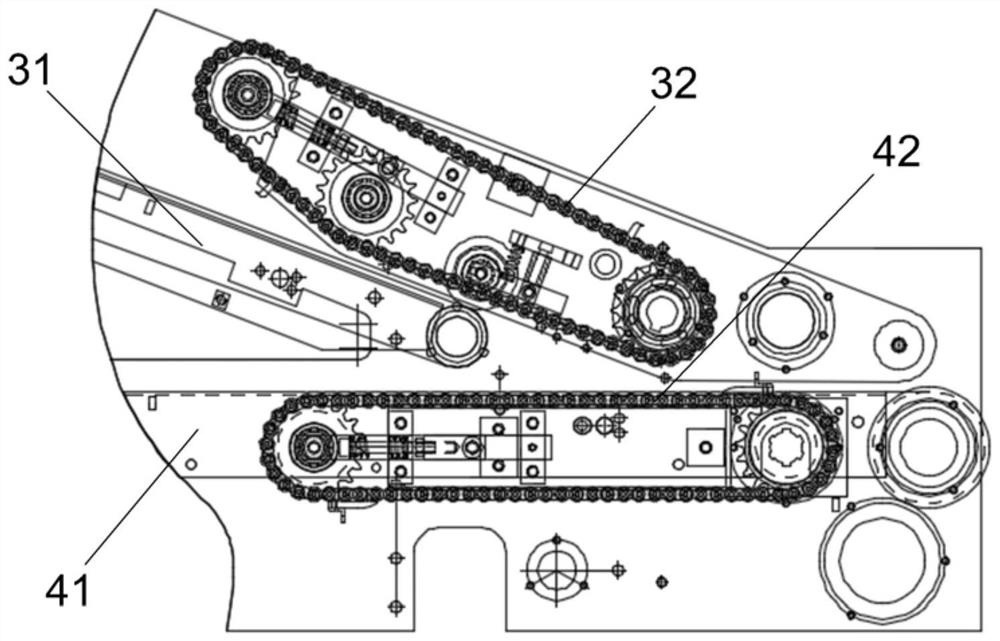

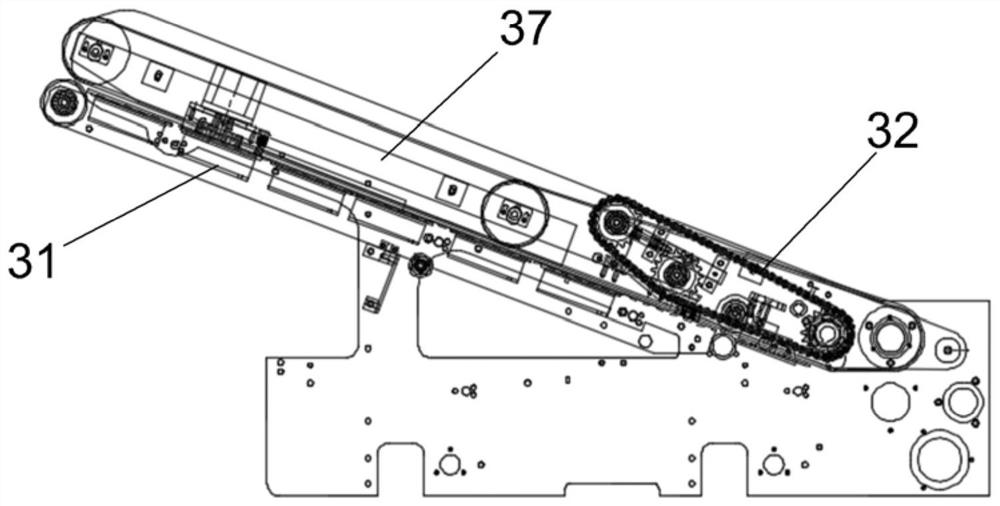

[0048] refer to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com