Vest bag folding equipment

A technology of folding equipment and vest bags, which is applied to paper product packaging, packaging, and strapping machine parts, etc., can solve the problems of low production efficiency and high labor cost of manual folding and strapping, and achieve simple structure, good folding effect, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

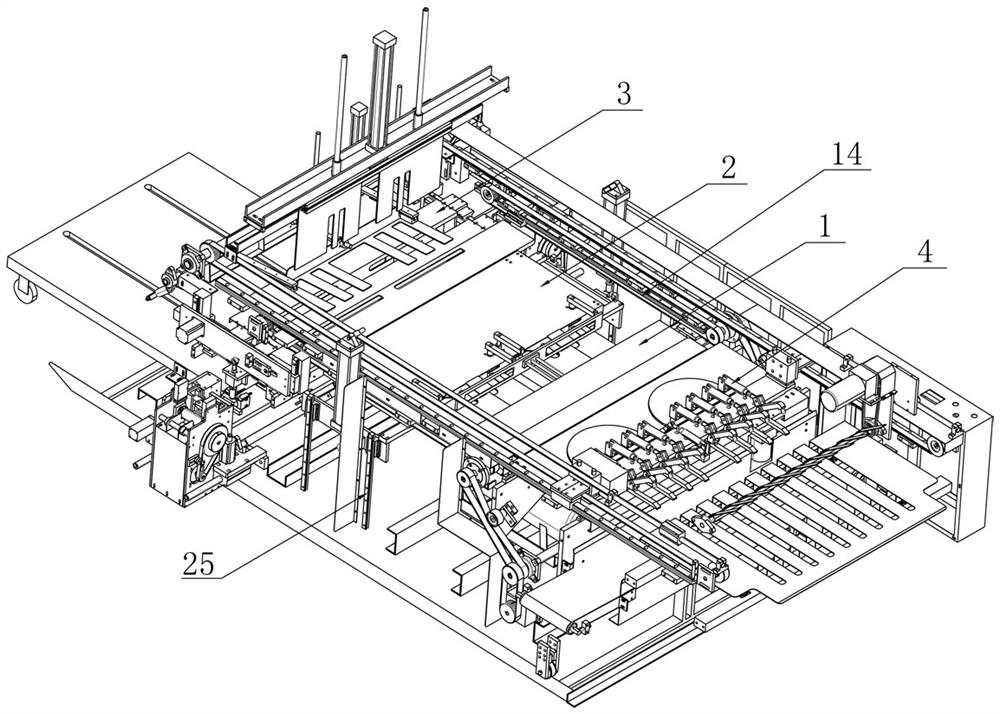

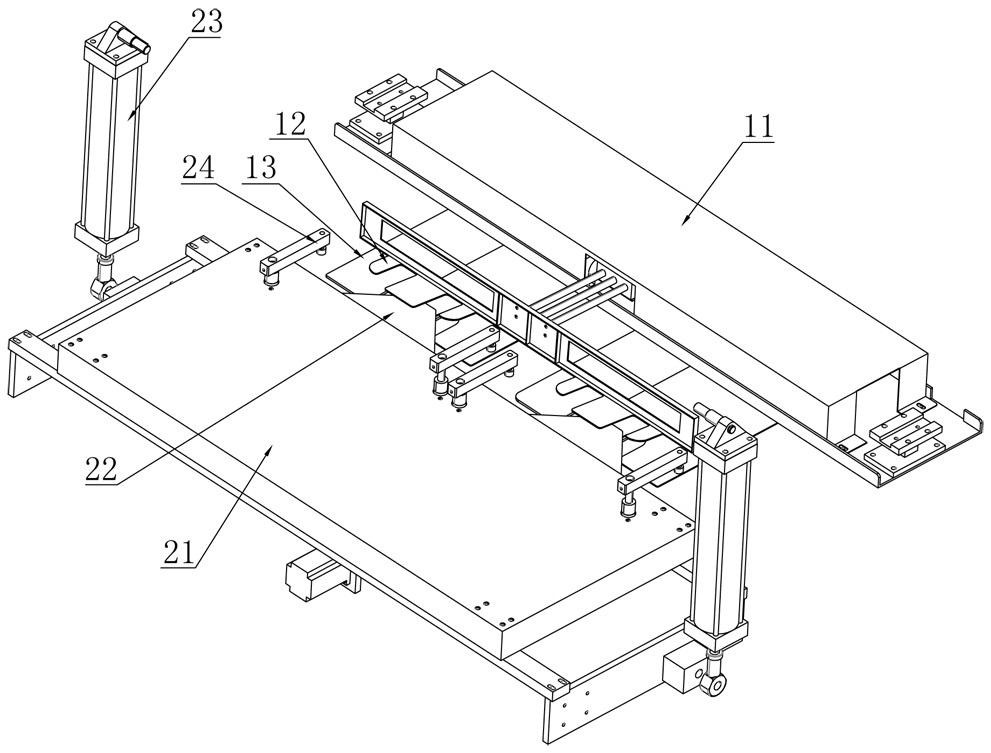

[0024] Such as figure 1 , figure 2 and Figure 4 As shown, the vest bag folding equipment includes a pinching and folding ear mechanism 1, a bag body receiving mechanism 2, a bag body folding mechanism 3 and a bag grasping robot 4, and the pinching and folding ear mechanism 1 travels between the bag body receiving mechanism 2 and the bag body. body folding mechanism 3, the pinch ear folding mechanism 1 cooperates with the bag receiving mechanism 2 to fold ears, and the pinch ear folding mechanism 1 cooperates with the bag body folding mechanism 3 to fold.

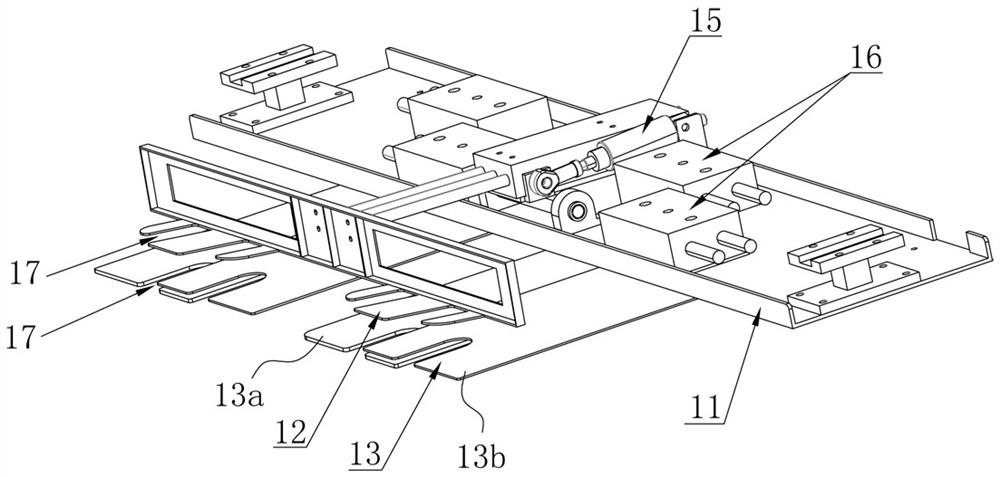

[0025] Such as figure 2 and image 3 As shown, the pinching and folding ear mechanism 1 includes a translation worktable 11, a telescopic pressing plate 12 and a pair of folding ear plates 13 for folding two hand straps, that is, a left folding ear plate 13a and a right folding ear plate 13b, that is to say two The folded ear plates have a height difference, and no collision will occur during the movement. The telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com