Method for superhydrophobic modification of substance containing collagen fibers, method for making leather without tanning agent, and leather products

A technology of superhydrophobic modification and skin collagen, which is applied in the field of tanning, which can solve the problems of chrome tanning agent pollution, unstable performance, and poor durability of tanning effects, and achieve increased shrinkage temperature and denaturation temperature, excellent mechanical properties, and excellent tanning effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

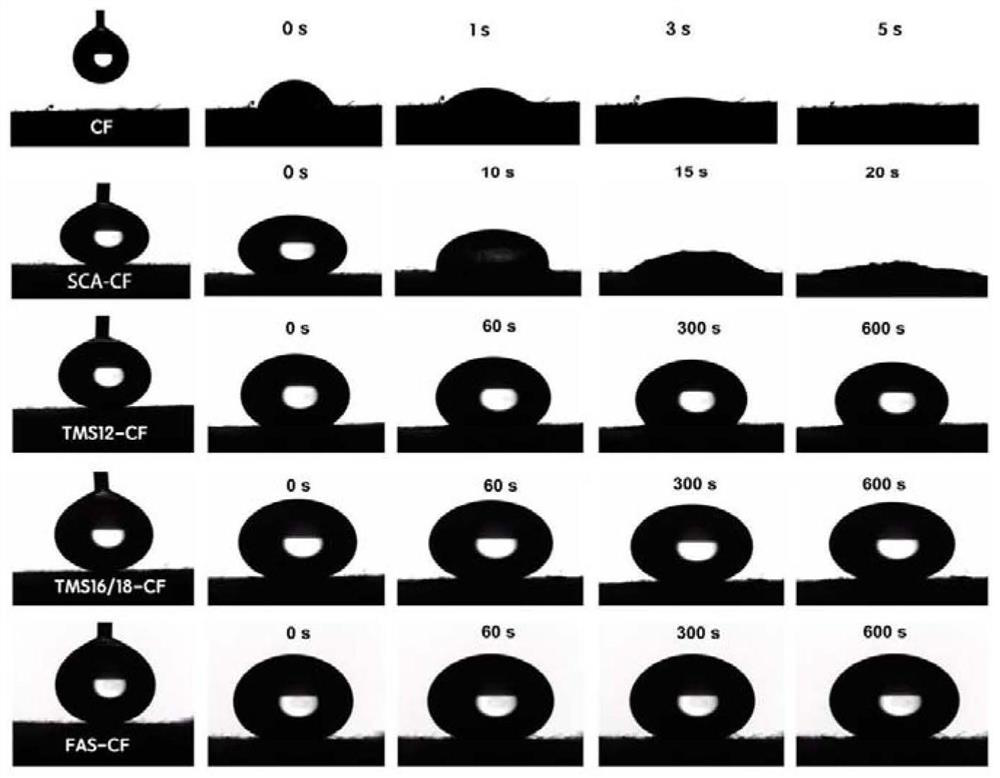

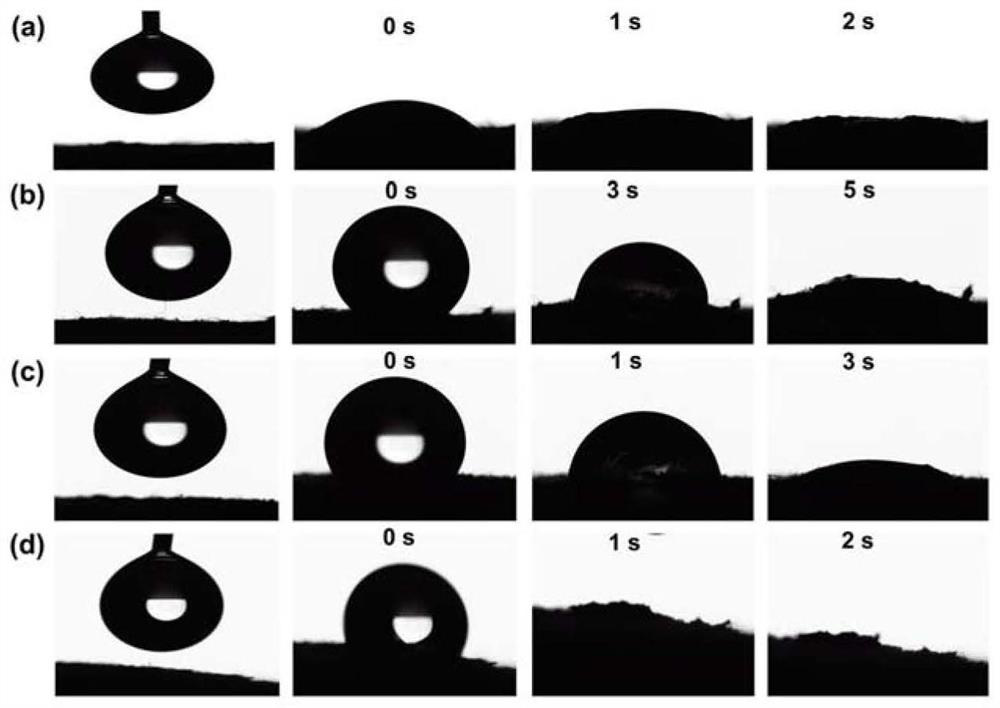

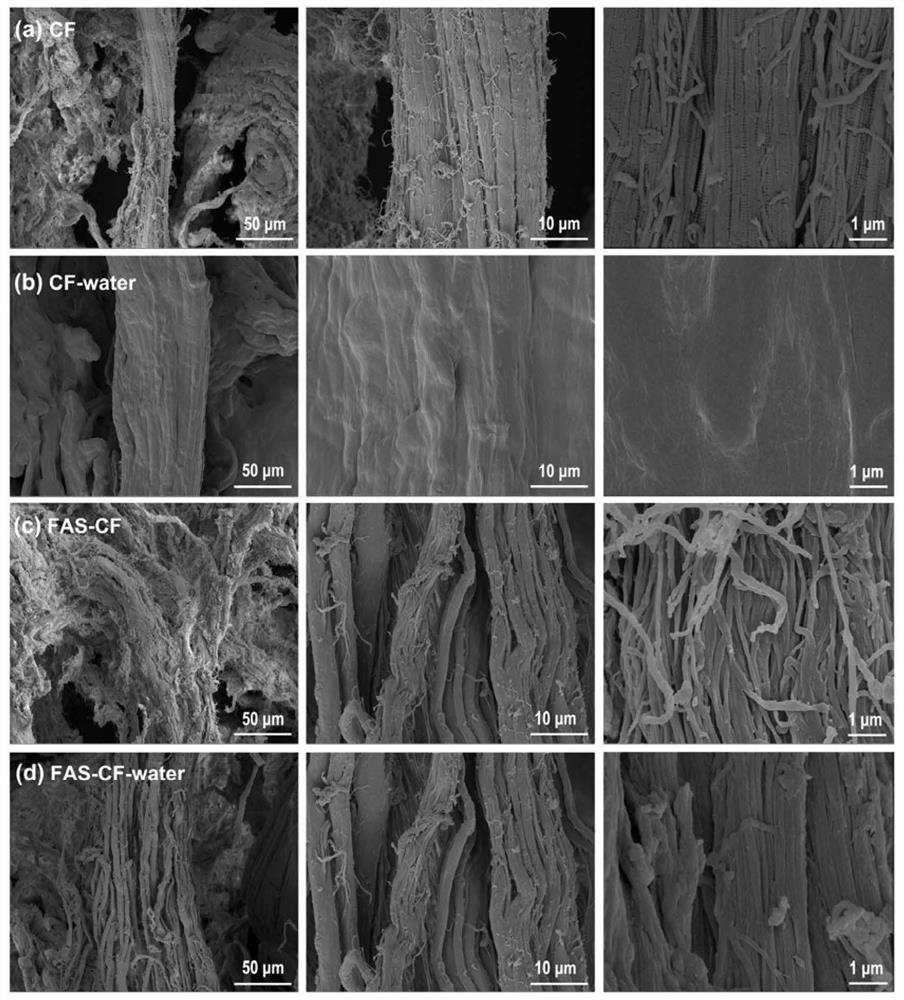

[0092] The present embodiment provides the superhydrophobic modification method of the material containing skin collagen fiber, comprises the following steps:

[0093] (1) Soak the skin collagen fiber raw material in water for more than 12 hours to ensure full penetration, then add 10wt% acetic acid aqueous solution and / or 10wt% sodium bicarbonate aqueous solution to the water to adjust the pH to 6.5, and then filter the excess water. The skin collagen fibers were soaked and stirred in absolute ethanol, repeated 4 times, soaked for 2 hours each time, and then vacuum filtered to obtain skin collagen fibers with a water content of about 16.3%.

[0094] (2) Take 10 g of skin collagen fibers treated in step (1), immerse them in 100 mL of isopropanol solution containing 3 g of perfluorodecyltriethoxysilane, soak and stir at 25°C for 24 hours, and then remove by suction filtration The excess liquid was dried at 120°C for 4 hours.

[0095] (3) Wash the skin collagen fibers obtained ...

Embodiment 2

[0099] The present embodiment provides the superhydrophobic modification method of the material containing skin collagen fiber, comprises the following steps:

[0100] (1) Soak the skin collagen fiber raw material in water for more than 12 hours to ensure full penetration, then add 10wt% acetic acid aqueous solution and / or 10wt% sodium bicarbonate aqueous solution to the water to adjust the pH to 6.5, and then filter the excess water. The material containing skin collagen fibers was soaked in absolute ethanol and stirred, and repeated 4 times, soaking for 2 hours each time, and then vacuum filtered to obtain skin collagen fibers with a water content of about 16.3%.

[0101] (2) Take 10 g of skin collagen fibers treated in step (1), immerse them in 100 mL of isopropanol solution containing 1 g of octadecyltrimethoxysilane, soak and stir at 30°C for 12 hours, and then remove excess by suction filtration. Liquid, dry at 105°C for 4h.

[0102] (3) Wash the skin collagen fibers ob...

Embodiment 3

[0104] The present embodiment provides the superhydrophobic modification method of the material containing skin collagen fiber, comprises the following steps:

[0105] (1) Soak the skin collagen fiber raw material in water for more than 12 hours to ensure full penetration, then add 10wt% acetic acid aqueous solution and / or 10wt% sodium bicarbonate aqueous solution to the water to adjust the pH to 6.5, and then filter the excess water. The material containing skin collagen fibers was soaked in absolute ethanol and stirred, and repeated 4 times, soaking for 2 hours each time, and then vacuum filtered to obtain skin collagen fibers with a water content of about 16.3%.

[0106] (2) Take 12 g of skin collagen fibers treated in step (1), immerse them in 100 mL of isopropanol solution containing 2 g of hexadecyltrimethoxysilane, soak and stir for 7 hours at 35 ° C, and remove excess by suction filtration. Liquid, dry at 120°C for 4h.

[0107] (3) Wash the skin collagen fiber obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap