Single-diaphragm low-resistance backflow preventer

A backflow preventer and low-resistance technology, applied in current collectors, hydroelectric power generation, machines/engines, etc., can solve the problems of large water head loss, inability to open the anti-backflow mode in advance, poor anti-backflow effect, etc., to reduce water pressure loss volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to more clearly understand the above objects, features and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

[0045] In the following description, many specific details are set forth in order to fully understand the present invention. However, the present invention can also be implemented in other ways than described here. Therefore, the present invention is not limited to the specific embodiments disclosed below. limit.

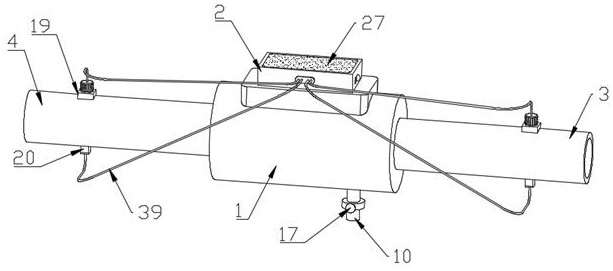

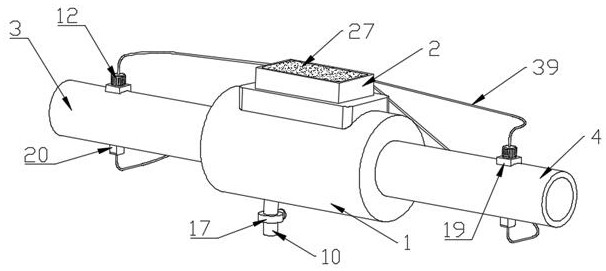

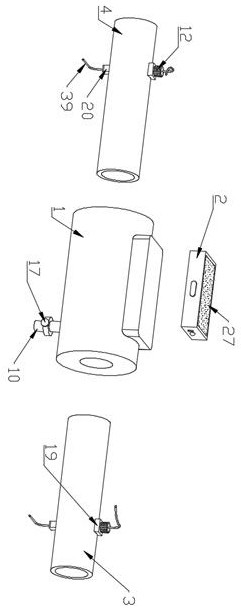

[0046] A single-diaphragm low-resistance backflow preventer of this embodiment, refer to Figure 1-14 : Including main pipe 1, drive assembly, detection assembly and control box 2.

[0047] The nozzles of the input and output ends of the main pipe 1 are respectively sealed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com