Water meter housing

A technology of meter body and shell, applied in the field of water meter shell, can solve the problems of great influence on the environment and human body, easy generation of pores, shrinking walls, and high cost of brass casting, and achieves good flow consistency, light and thin materials, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

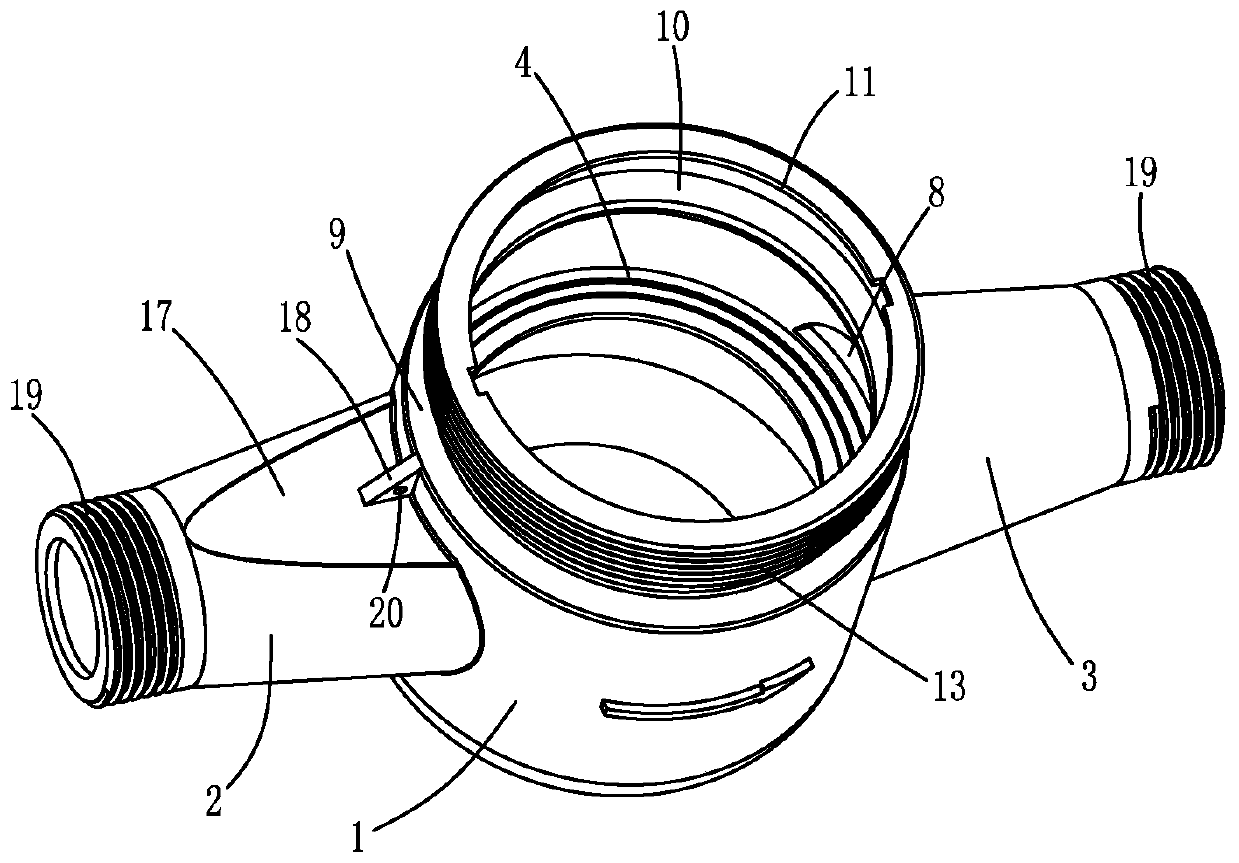

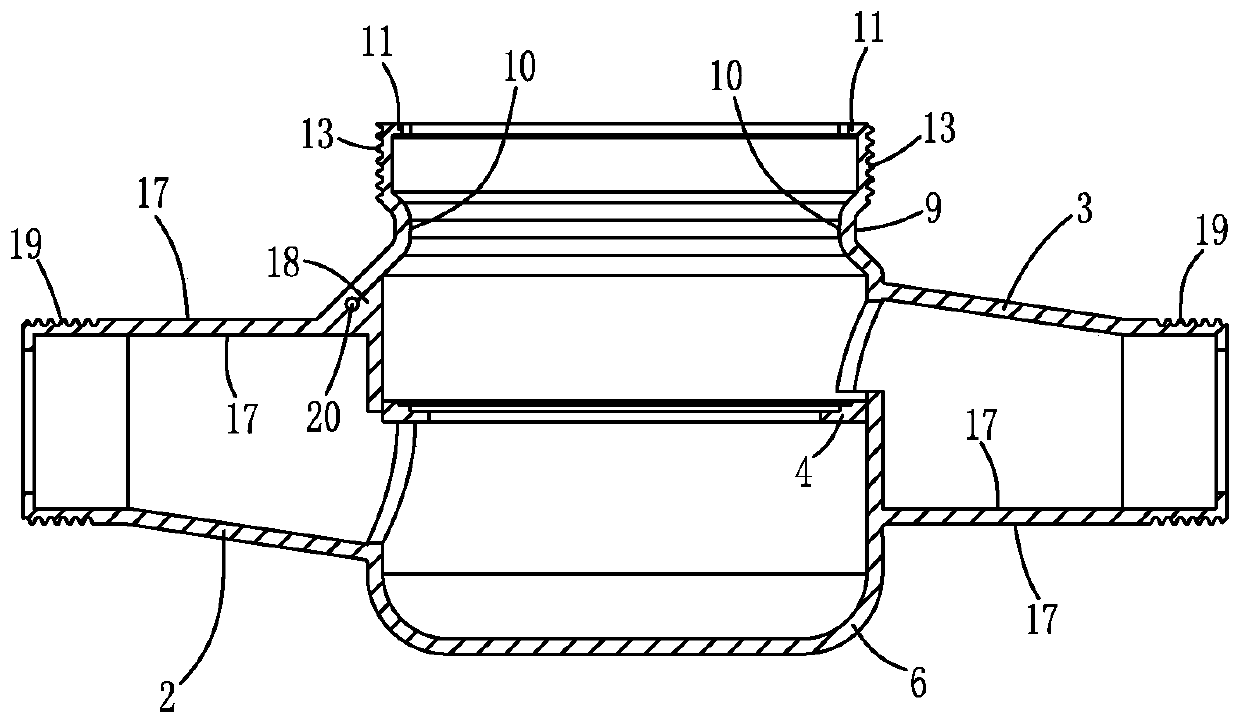

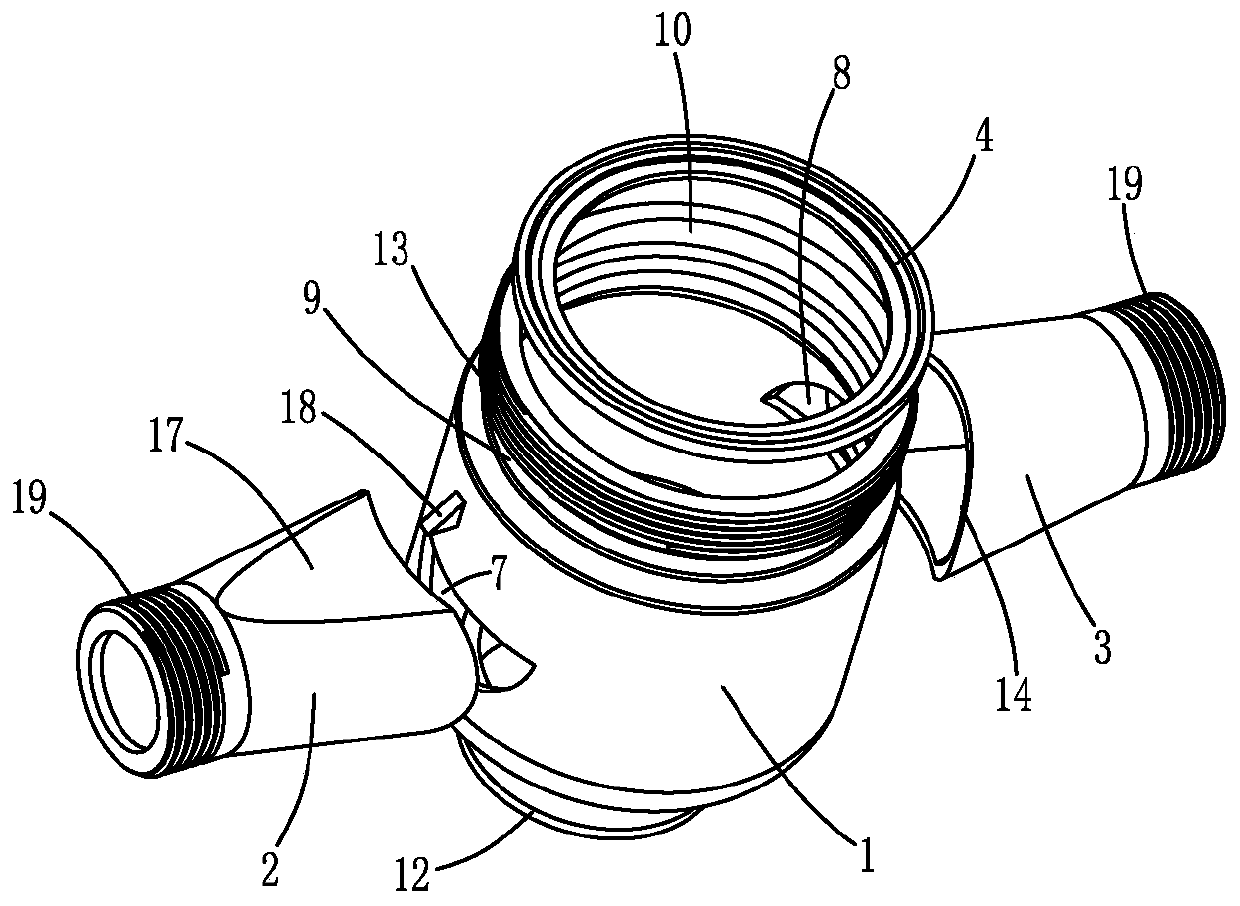

[0020] the following to Figure 1 to Figure 8 Shown, the specific embodiment of the present invention is described.

[0021] A light and thin water meter housing, such as Figures 1 to 4 As shown, it includes a watch body 1, a water inlet pipe 2 and an outlet pipe 3 arranged on the left and right sides of the watch body 1, and a movement positioning ring 4 arranged in the watch body 1, the watch body 1, the water inlet pipe 2, and the water outlet pipe 3 They are stamped from steel pipes of corresponding diameters, and the steel pipes used as raw materials are all made of high-quality carbon structural steel pipes. The lower end of the meter body 1 forms an arc-shaped contraction ring 6 surrounding the lower port 5, and the left and right sides of the meter body 1 are respectively provided with a water inlet 7 and a water outlet 8, and the neck of the meter body 1 is stamped on the outer wall of the meter body 1 to form an annular shrinkage 9 , the inner convex ring 10 is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com