Drum type washing machine

A drum type washing machine, drum technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of not being able to get beat washing, not being able to become beat washing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

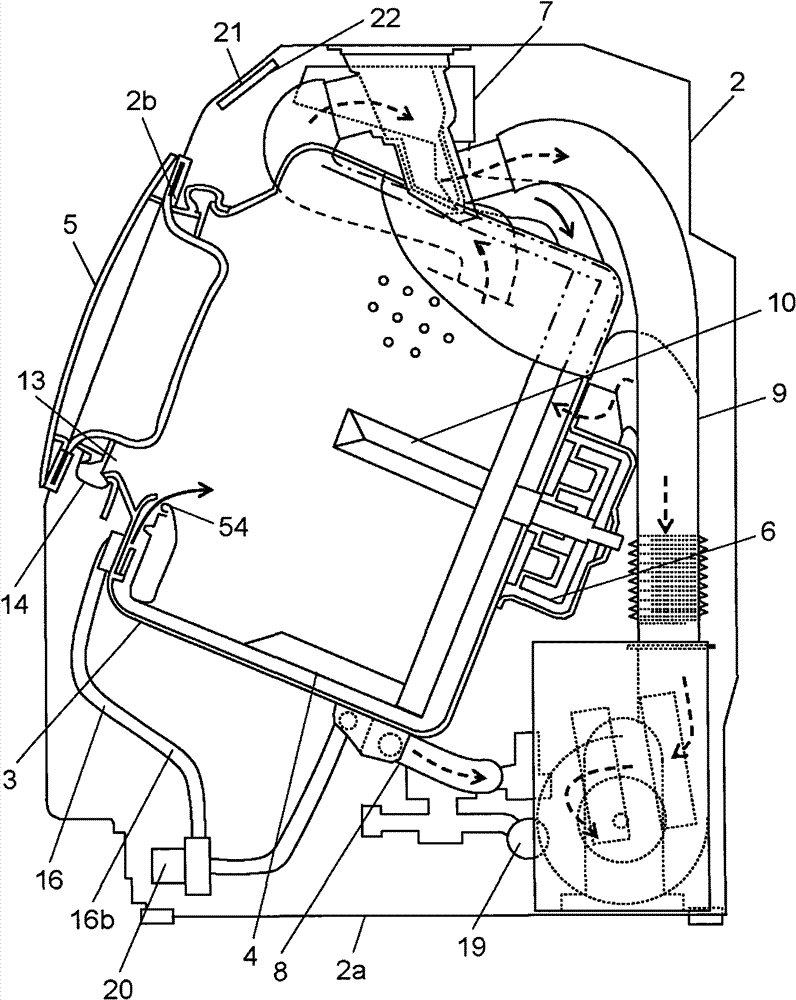

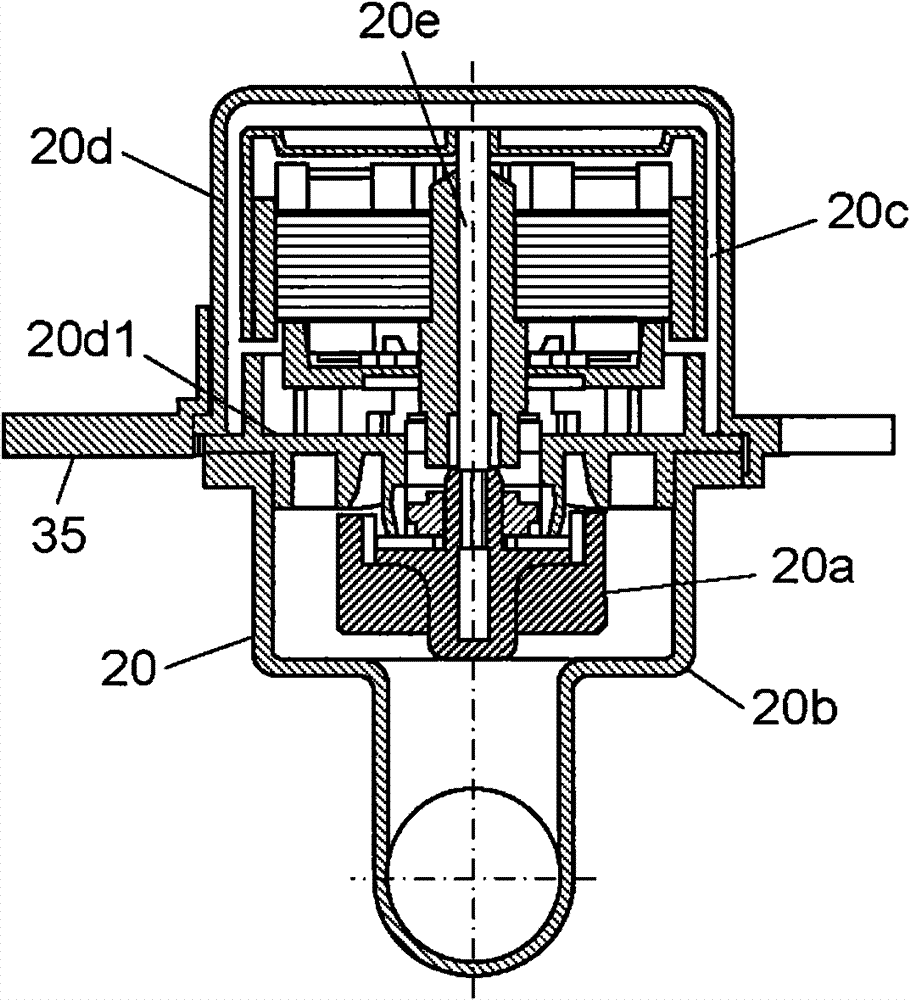

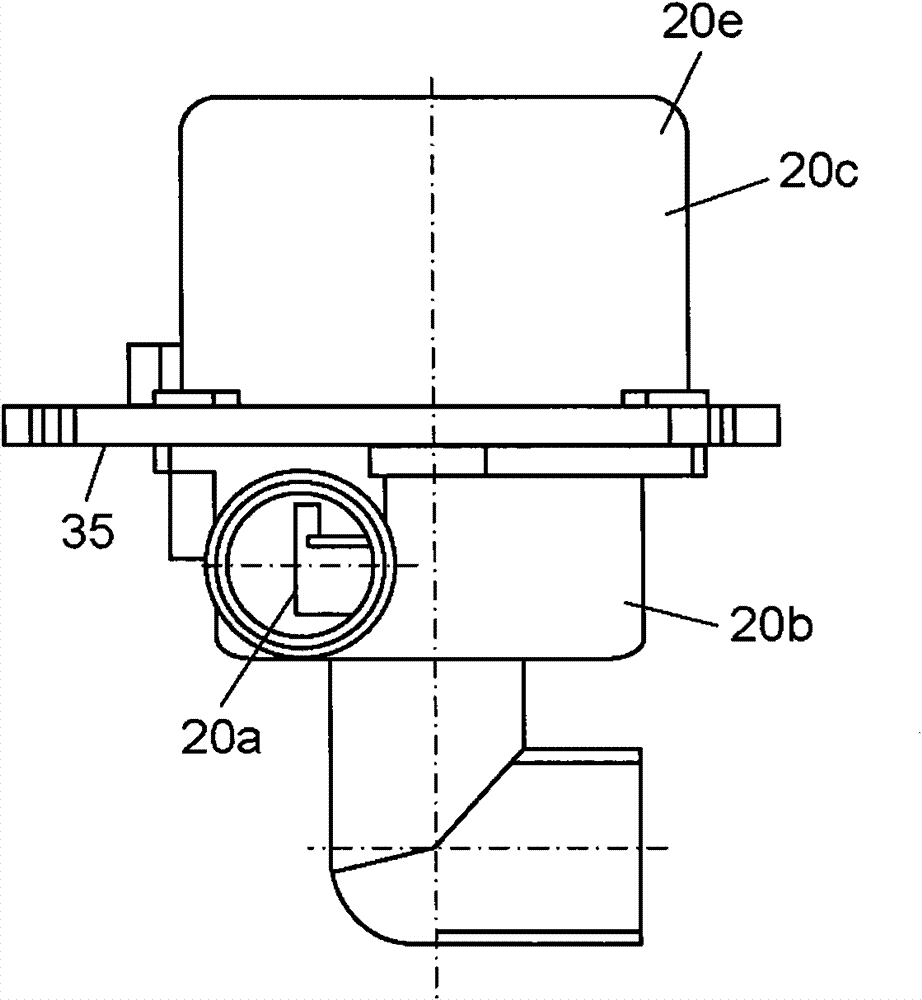

[0029] figure 1 It is a cross-sectional view showing a schematic structure of the front-loading washing machine according to Embodiment 1 of the present invention, Figure 2A is a sectional view of a circulation pump used in the drum type washing machine, Figure 2B It is a side view of the circulation pump used in this front-loading washing machine.

[0030] The front-loading washing machine according to Embodiment 1 has automatic control according to the mode setting and control program. figure 1 The motor 6, water supply system 7, drainage system 8, and drying system 9 shown perform at least the functions of a washing process, a rinsing process, a dehydration process, and a drying process. However, the drying system 9 can be omitted. In addition, in addition to the above, the water circulation system 16 can be used to circulate the washing water in the water tank 3 during the washing preparation process, the washing process, and the rinsing process as needed, so as to ac...

Embodiment approach 2

[0053] Image 6 It is the rear view which looked at the front wall of the water tank of the front-loading-type washing machine concerning Embodiment 2 of this invention from the direction of the rotation axis of a rotary drum. In Embodiment 2 of the present invention, the same reference numerals are assigned to the same constituent elements as in Embodiment 1, description thereof will be omitted, and different points will be described.

[0054] Such as Image 6 As shown, in a plane perpendicular to the direction of the rotating shaft 10 of the rotating drum 4 , the line connecting the rotation center of the rotating drum 4 and the water inlet 51 is the first line 61 . Then, on both sides of the first line 61 in this plane, a plurality of discharge ports 55d having different distances from the water inlet 51 are provided. The line connecting the center of rotation of the rotary drum 4 and the discharge port 55d near the water inlet 51 is the second line 62, and the line conne...

Embodiment approach 3

[0067] Figure 7 It is the rear view which looked at the front wall of the water tank of the front-loading-type washing machine concerning Embodiment 3 of this invention from inside. In Embodiment 3 of the present invention, the same components as those in Embodiment 1 or Embodiment 2 are assigned the same reference numerals, and description thereof will be omitted.

[0068] Such as Figure 7 As shown, the opening cross-sectional area of the water inlet 51 is S51, and in the discharge port 55d arranged at two positions on the left and right with respect to the rotating shaft 10, the front (the front here refers to Figure 5 The opening cross-sectional area of the ejection port 55d on the left side is S55d (L), and the front (the front here refers to Figure 5 The opening cross-sectional area of the ejection port 55d on the right side is S55d(R), the cross-sectional area ratio S55d(L) / S51=SL, and the cross-sectional area ratio S55d(R) / S51=SR.

[0069] When the cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com