Gap treatment method for aerogel internal thermal insulating layer

A treatment method and aerogel technology, which are applied to offensive equipment, projectiles, self-propelled projectiles, etc., can solve the problem of poor processing technology of stepped lap joints, difficult and tight bonding of stepped lap joints, and affect the thermal insulation effect of the thermal insulation layer. and other problems, to achieve the effect of easy control of the thickness of the thermal insulation layer, ideal relative position of the composition, and ensuring the effect of gap treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for treating gaps in an airgel inner heat insulation layer, using the following process steps:

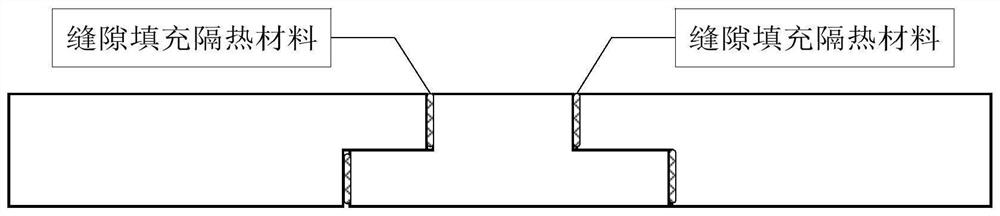

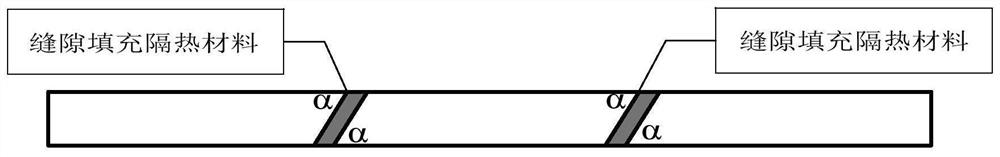

[0049] ①Pre-assemble a number of airgel inner heat insulation layers made of silica airgel on the inner surface of the cabin, and process inclined surfaces such as figure 2 As shown, the inclination angle α: 45°, the width of the gap between the thermal insulation layers in the airgel is determined to be about 1.5 mm.

[0050] ②According to the width of the gap between the thermal insulation layers in the airgel, the basalt fiber reinforced silica airgel material with a thickness of 2mm is selected as the gap filling thermal insulation material, and the gap filling thermal insulation material width is the same as that in the airgel. The slope of the heat insulation layer has the same width and the same length as the length of the slope of the heat insulation layer in the airgel.

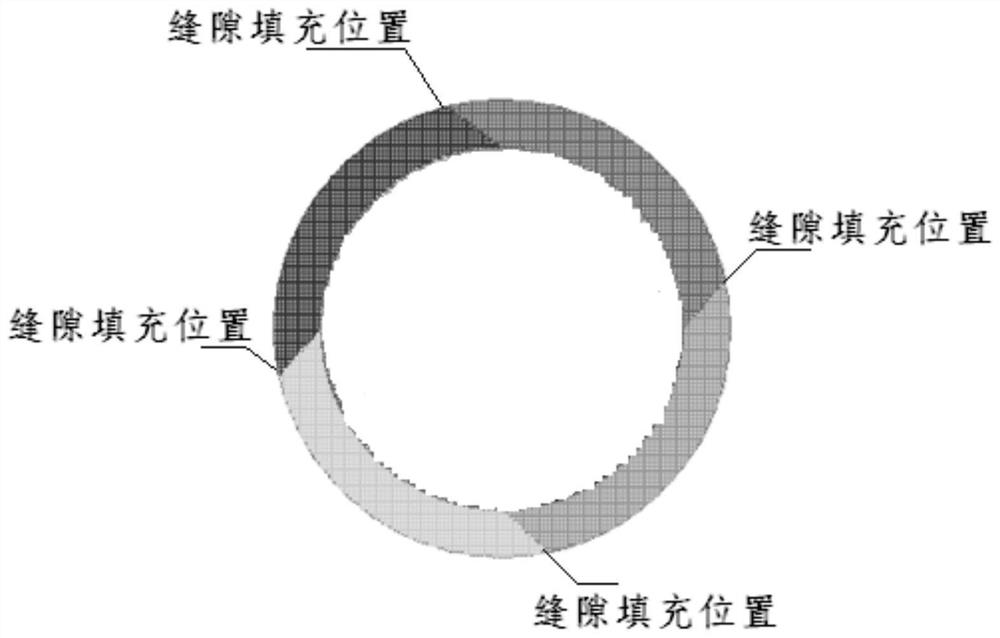

[0051] ③Fill the gap with insulation material according to image 3 The extrusion f...

Embodiment 2

[0054] A method for treating gaps in an airgel inner heat insulation layer, using the following process steps:

[0055] ①Pre-assemble a number of airgel inner heat insulation layers made of silica airgel on the inner surface of the cabin, and process inclined surfaces such as figure 2 As shown, the inclination angle α: 45°, the width of the gap between the thermal insulation layers in the airgel is determined to be about 0.5 mm.

[0056] ②According to the width of the gap between the inner heat insulation layers of the airgel, the reinforced fiber gap treatment material made of basalt fiber with a thickness of 1mm is selected as the gap filling heat insulation material, and the width of the gap filling heat insulation material is equal to that of the airgel The slope of the inner heat insulation layer has the same width and the same length as the length of the slope of the airgel inner heat insulation layer.

[0057] ③Fill the gap with insulation material according to imag...

Embodiment 3

[0060] Embodiment 3 is basically the same as Embodiment 1, the difference is:

[0061] In step ①, a plurality of airgel inner heat insulation layers made of silica airgel are pre-assembled on the inner surface of the cabin, and the inclined surfaces are lapped as follows: figure 2 As shown, the inclination angle α: 20°, the width of the gap between the heat insulation layers in the airgel is determined to be about 1.5 mm. The gap treatment method is the same as that of Example 1.

[0062] The heat insulation performance of the sample prepared in Example 3 is not much different from the heat insulation performance of the sample prepared in Example 1, but the end of the inclined angle is easily damaged during processing, transportation, and handling, which affects the airgel interior. The integrity of the thermal insulation layer, thus affecting the thermal insulation effect of the overall inner thermal insulation layer.

[0063] The 20mm thick sample prepared in this example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com