Online monitoring method for mechanical properties of 3D printing concrete based on neural network

A 3D printing and neural network technology, applied in the direction of measuring devices, scientific instruments, instruments, etc., can solve the problems of difficult monitoring and control of the mechanical properties of 3D printed concrete printed products, increase the amount of testing labor, etc., to save manpower and simplify the testing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

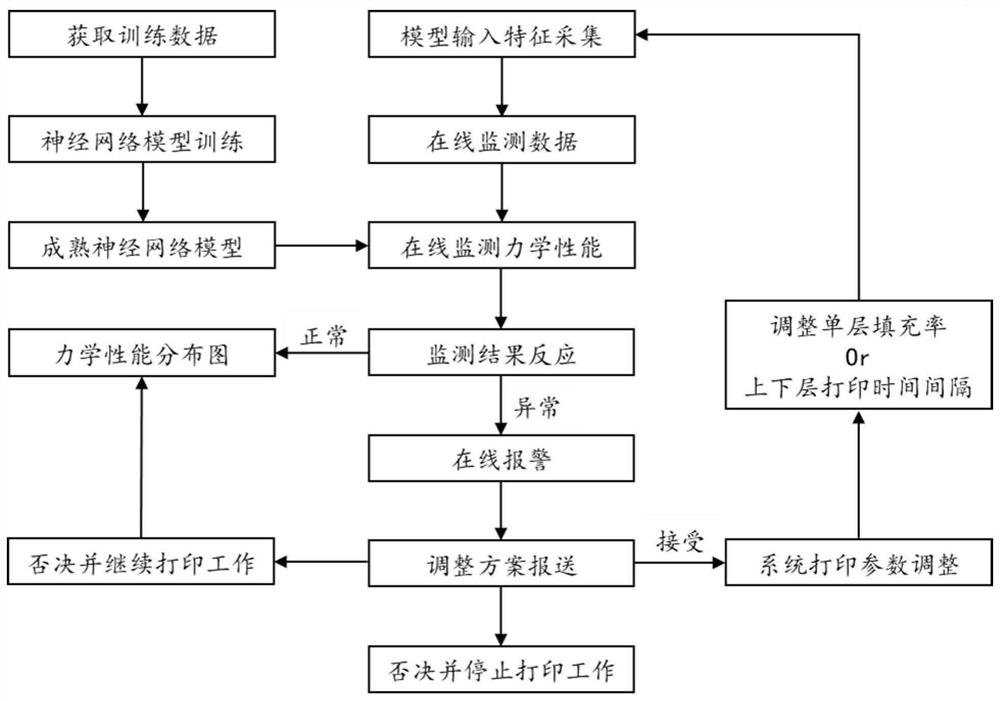

[0053] This embodiment provides a neural network-based online monitoring method for the mechanical properties of 3D printed concrete, which performs online monitoring of the mechanical properties of 3D printed concrete during the printing process, including the following steps:

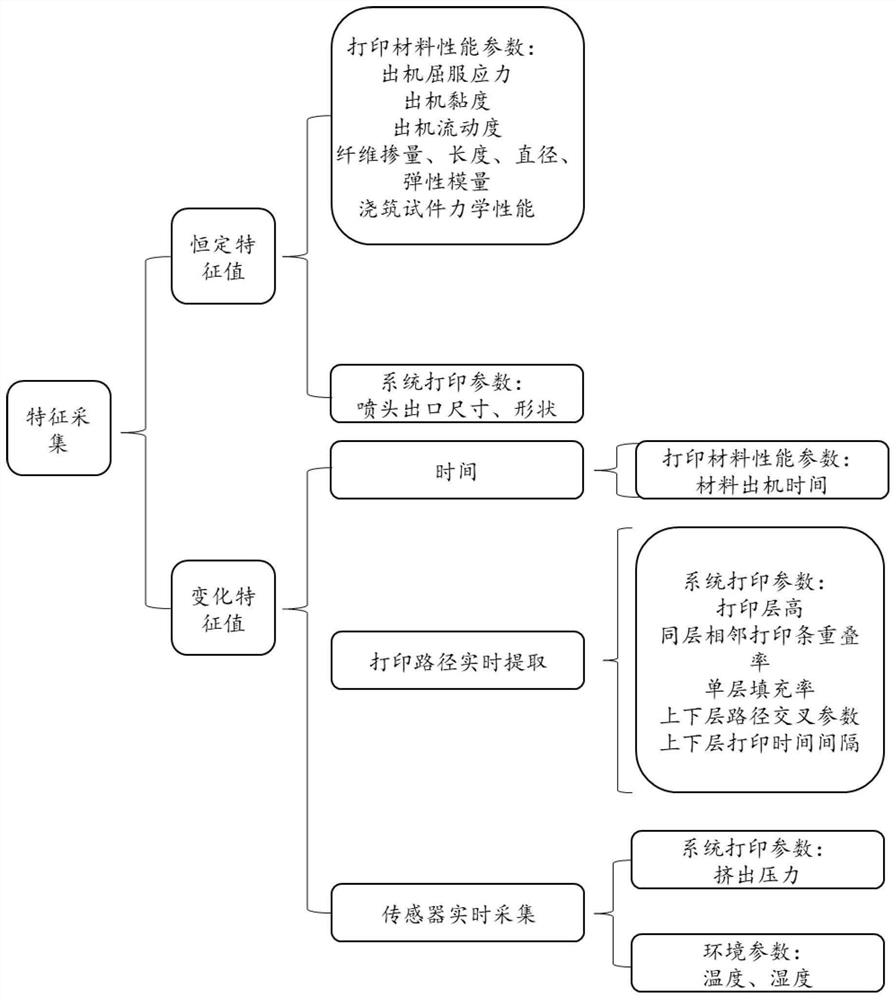

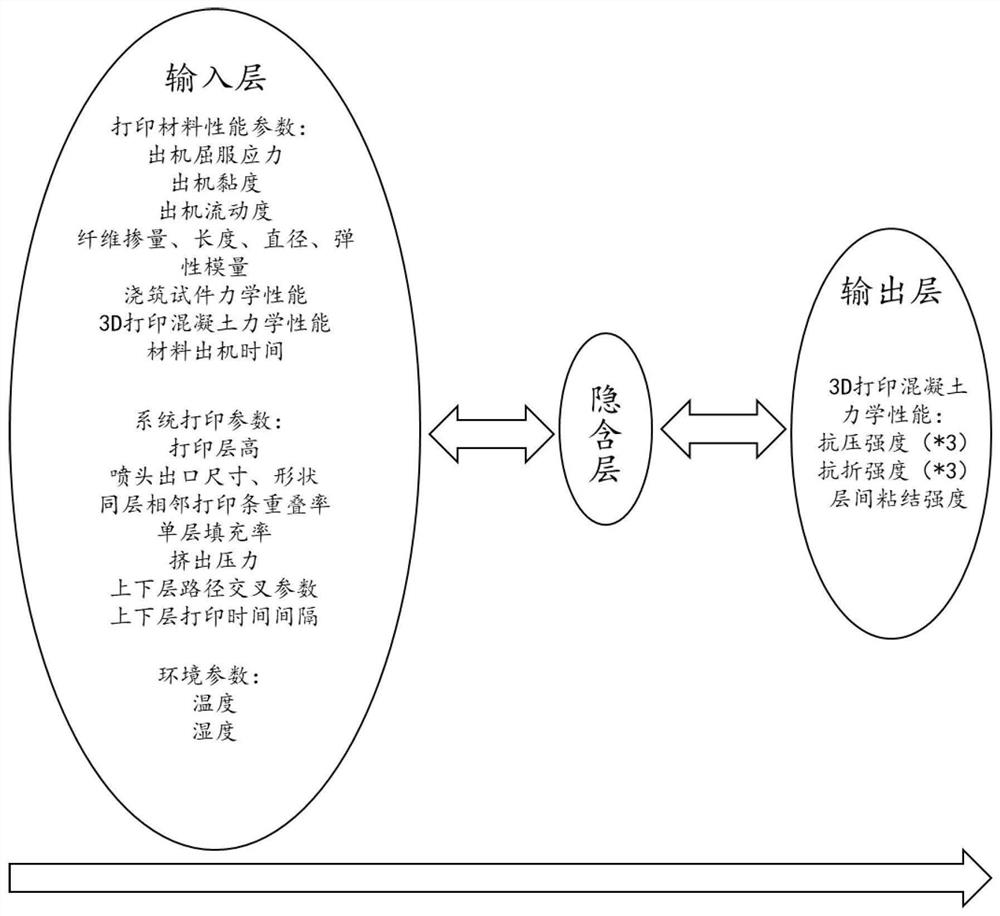

[0054] Step 1. The neural network model is trained and matured with the performance parameters of the printing material, system printing parameters and environmental parameters as the training data, and the mechanical properties of the 3D printed concrete as the output value. The input data of the neural network model includes:

[0055] Printing material performance parameters: exit yield stress, exit viscosity, exit fluidity, fiber content, fiber length, fiber diameter, fiber elastic modulus, material exit time, mechanical properties of pouring specimens, mechanical properties of 3D printed concrete ;

[0056] System printing parameters: printing layer height, nozzle outlet size, nozzle outlet shape...

Embodiment 2

[0067] This embodiment provides a neural network-based online monitoring method for the mechanical properties of 3D printed concrete, which is used to predict the mechanical properties of 3D printed concrete before printing, including the following steps:

[0068] Step 1. The neural network model is matured by using the performance parameters of the printing material and the printing parameters of the system as the training data, and the mechanical properties of the 3D printed concrete as the output value. The input data of the neural network model includes:

[0069] Printing material performance parameters: exit yield stress, exit viscosity, exit fluidity, fiber content, fiber length, fiber diameter, fiber elastic modulus, mechanical properties of pouring specimens, mechanical properties of 3D printed concrete;

[0070] System printing parameters: printing layer height, nozzle outlet size, nozzle outlet shape, overlapping rate of adjacent printing strips in the same layer, si...

Embodiment 3

[0074] This embodiment provides a neural network-based online monitoring method for the mechanical properties of 3D printed concrete, which is used to calculate the mechanical properties of 3D printed concrete after printing, including the following steps:

[0075] Step 1. The neural network model is trained and matured with the performance parameters of the printing material, system printing parameters and environmental parameters as the training data, and the mechanical properties of the 3D printed concrete as the output value.

[0076] Step 2. Transfer the actual printed constant eigenvalues, time-varying eigenvalues, eigenvalues extracted from the printing path, and representative values of changing eigenvalues collected by the sensor to the mature neural network model trained in step 1 to calculate the finished product of 3D printed concrete Mechanical properties, draw the distribution map of mechanical properties of 3D printed concrete printed products.

[0077] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com