Laser forming method of flexible circuit board

A flexible circuit board and laser technology, applied to the formation of electrical connection of printed components, printed circuit, printed circuit manufacturing, etc., can solve the problems of large bending stress of wiring structure, wiring structure breakage, etc., and achieve the effect of reducing stress and good electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The object of the present invention is to provide a laser forming method of a flexible circuit board, so as to prevent the circuit layer from being damaged by stress during bending, resulting in failure of the flexible circuit board.

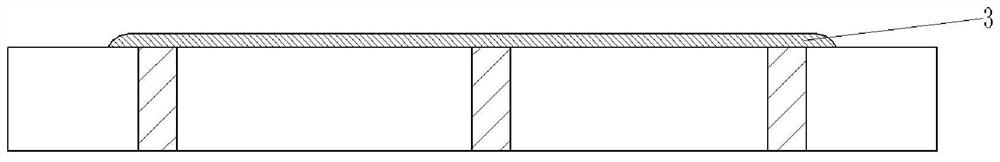

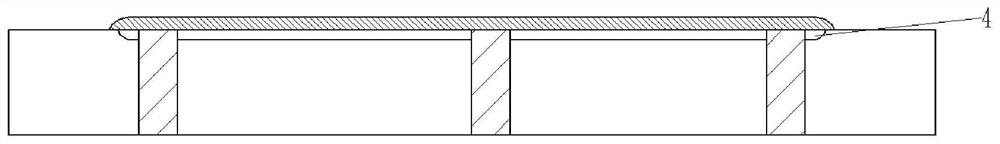

[0022] join Figure 1-6 , the laser formation method of conductive column of the present invention, comprises the following steps:

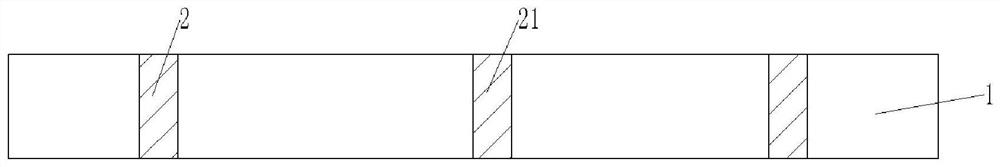

[0023] see figure 1 , provide a flexible polymer sheet 1, the flexible polymer sheet 1 includes a first polymer material, the first polymer material is a flexible material, such as polyethylene terephthalate, polyimide Or polymer materials such as polyethylene naphthalate. The thickness of the flexible polymer sheet 1 may be 1-2 mm, and it may be a prefabricated sheet structure.

[0024] Next, a plurality of first via holes are formed in the flexible polymer sheet 1 , and the first via holes are formed by etching or laser drilling. Fill the first via hole with a metal material to form a plurality of firs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap