Automatic welding material belt for brocade silk threads

A technology of automatic welding and brocade thread, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low production efficiency and urgent need for mechanical automation in the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

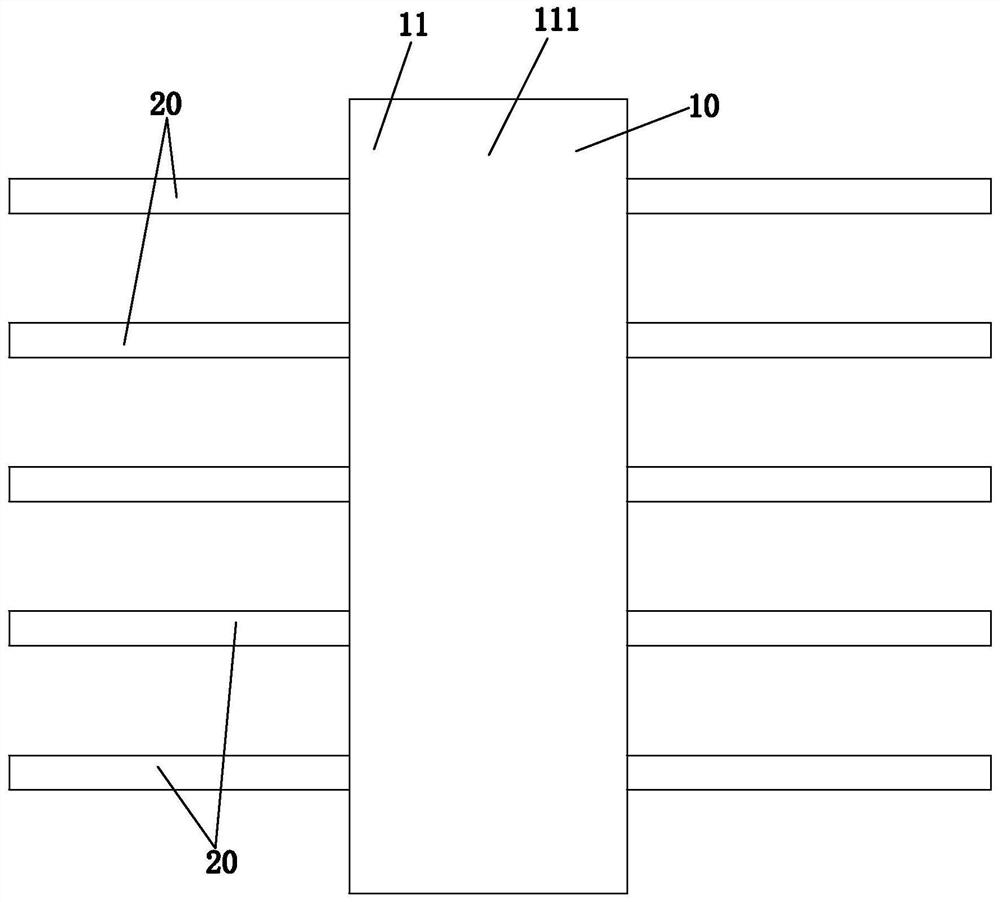

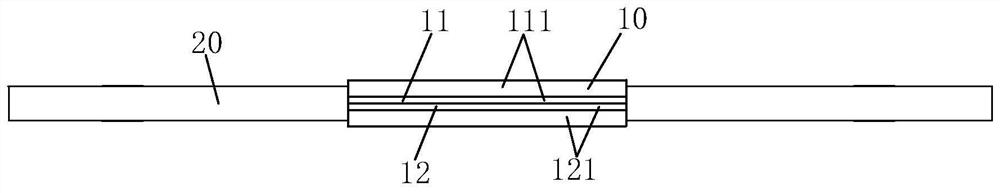

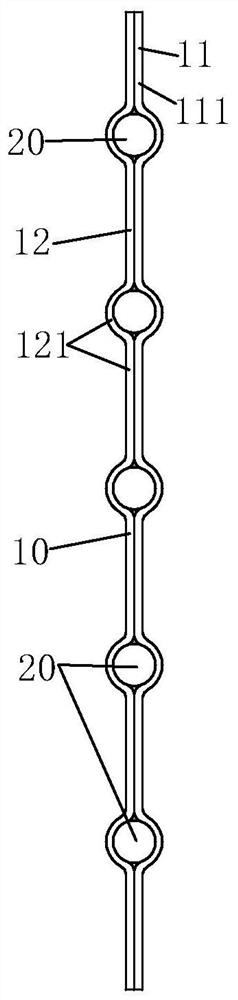

[0019] refer to Figure 1 to Figure 3 According to the present invention, the brocade wire automatic soldering tape includes a group of adhesive tape components 10 and at least three brocade wires 20 arranged parallel to each other. In this embodiment, the number of brocade threads 20 is more than three.

[0020] The adhesive tape assembly 10 includes an upper adhesive tape 11 and a lower adhesive tape 12 . The upper adhesive tape 11 includes an upper adhesive tape 111 and an upper adhesive layer (not shown) that is bonded to the lower surface of the upper adhesive tape 111, and the lower adhesive tape 12 includes a lower adhesive tape 121 and an adhesive tape. The lower adhesive layer (not shown) is provided on the upper surface of the blanking belt 121 . The upper adhesive tape 11 is vertically wrapped on the upper parts of at least three brocade threads 20, the upper adhesive layer adheres to the upper parts of the brocade threads 20, and the lower adhesive tape 12 is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com