Injection molding cooling device for circuit board production

A cooling device and circuit board technology, which is applied in applications, household components, household appliances, etc., can solve the problems of metal dust incorporation, affecting the conductivity and accuracy of metal parts, and circuit boards containing metal impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

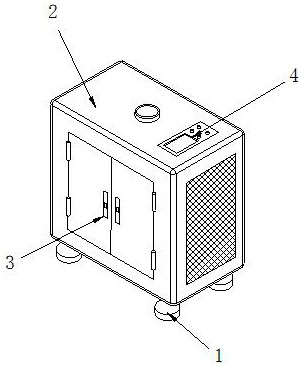

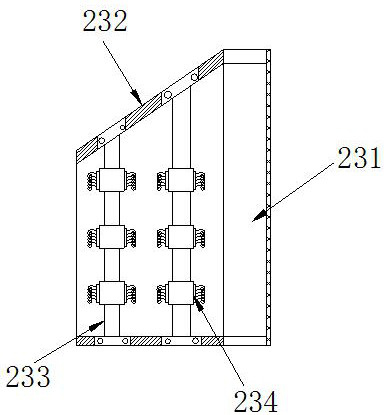

[0028] see Figure 1-Figure 7 , the specific embodiments of the present invention are as follows: an injection molding cooling device for circuit board production, its structure includes a base 1, a body 2, an access door 3, and a console 4, the top surface of the base 1 is embedded and connected to the bottom surface of the body 2, Both sides of the access door 3 are hingedly connected to the front of the body 2, and the console 4 is embedded in the top surface of the body 2; The inner layer of the casing 21 is embedded and connected to the bottom surface of the cooling bin 22, the left side of the air inlet pipe 23 is connected to the right side of the cooling bin 22 and connected by electric welding, and the bottom surface of the exhaust pipe 24 is connected to the top surface of the cooling bin 22. Connected and connected by electric welding, the bottom surface of the inner layer of the cooling chamber 22 is provided with a placement table structure with four rough arc-sha...

Embodiment 2

[0036] see Figure 8-Figure 9 , the specific embodiments of the present invention are as follows: the collection plate B44 includes a plate body C1, a movable groove C2, a suction head C3, and an upward handle C4, the inside of the plate body C1 and the movable groove C2 are integrally formed, and the suction head The bottom of C3 is embedded in the top surface of the board body C1, the middle section of the moving handle C4 is engaged with the inner layer of the movable groove C2, and there are fourteen suction heads C3, and the gaps between the fourteen suction heads C3 are evenly distributed on the board The top surface of the body C1 is made of magnetic materials, which is beneficial to increase the maximum capacity of metal particles and adsorb metals through strong metal adsorption.

[0037] Wherein, the upward moving handle C4 includes a rotating head C41, a lifting plate C42, a bullet frame C43, and a bouncing ball C44. The outer ring of the rotating head C41 is embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com