Traceless tire tread rubber and preparation method thereof

A technology for tire tread and tread rubber, which is applied in the field of tire tread rubber and can solve the problem that marks are not easy to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

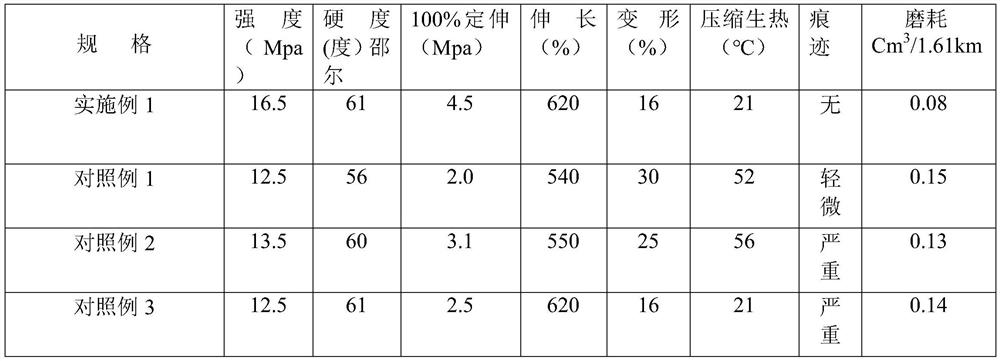

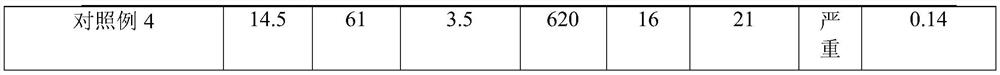

Examples

Embodiment 1

[0017] Raw materials are prepared according to the following proportions by weight: natural rubber SVR3L: 60 parts; Exxpro TM Special elastomer: 40 parts; carbon black N134: 5 parts; white carbon black: 70 parts; zinc oxide: 3 parts; stearic acid: 1.5 parts; antioxidant 4020: 1.5 parts; accelerator CZ: 0.6 parts; 0.8 parts; super silane SI747: 3.5 parts.

[0018] The preparation method comprises the following steps:

[0019] (1) Natural rubber SVR3L, Exxpro TM The special elastomer is mixed with carbon black N134 in an internal mixer for 240 seconds to make a carbon black masterbatch, and it is parked for more than 2 hours;

[0020] (2) After the master batch film obtained in step 1) is masticated in the internal mixer for 30 seconds, add white carbon black, zinc oxide, stearic acid, anti-aging agent, super silane and mix in the internal mixer for 120 seconds, made into rubber compound;

[0021] (3) After the mixed rubber prepared in step 2) is parked for more than 4 hours...

Embodiment 2

[0023] Raw materials are prepared according to the following proportions by weight: natural rubber SVR3L: 30 parts; Exxpro TM Special elastomer: 70 parts; carbon black N134: 10 parts; white carbon black: 60 parts; zinc oxide: 2.5 parts; stearic acid: 1.5 parts; antioxidant 4020: 1 part; accelerator CZ: 0.6 parts; 0.8 parts; super silane SI747: 3.2 parts.

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0026] Raw materials are prepared according to the following proportions by weight: natural rubber SVR3L: 70 parts; Exxpro TM Special elastomer: 60 parts; carbon black N134: 8 parts; white carbon black: 60 parts; zinc oxide: 2 parts; stearic acid: 1.5 parts; antioxidant 4020: 1 part; accelerator CZ: 0.2 parts; sulfur: 0.5 parts; super silane SI747: 3.2 parts.

[0027] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com