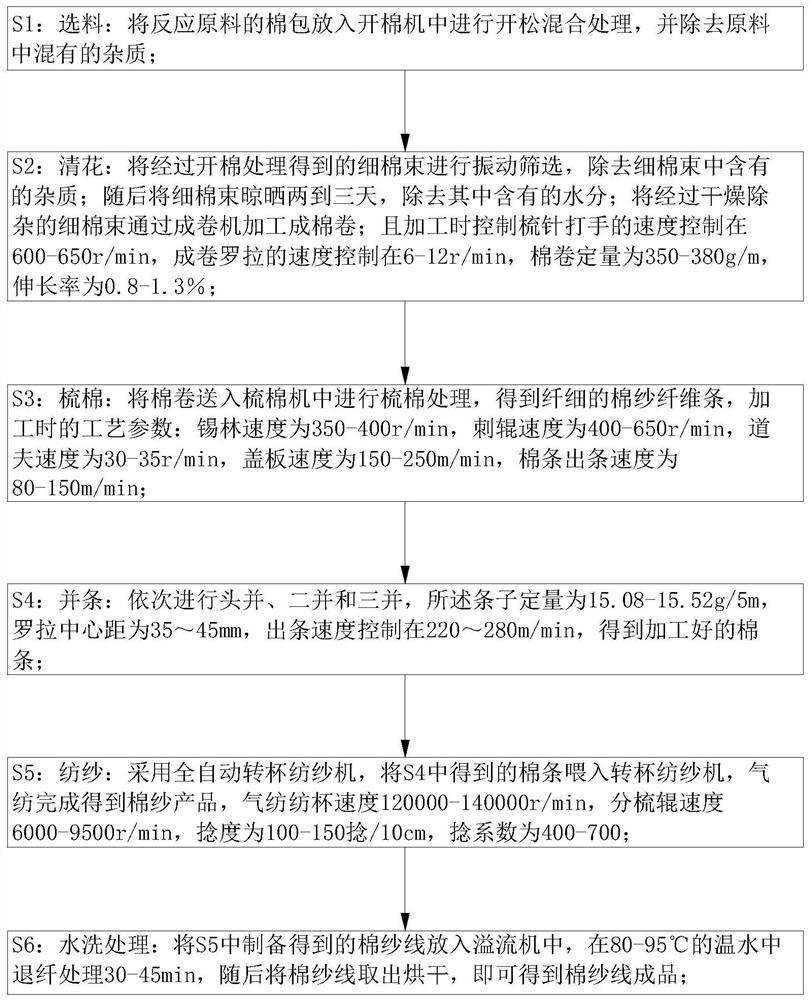

A kind of combed cotton yarn and its spinning process

A cotton yarn and process technology, which is applied in the field of combed cotton yarn and its spinning process, can solve the problems that affect the opening treatment of raw cotton, and the fibers are easily entangled between the blades and the teeth of the blades, so as to achieve a similar thickness and improve the quality. , to ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0062] Implementation method: Put the test subjects in the experimental group and the control group 1 into the fixed trays for fixation. During the six-week experiment, put the test subjects in the experimental group and the control group 1 outside for a period of time every day to accept the outdoor weather conditions. The impact of environmental changes; ensure that the test subjects in the experimental group and control group 1 are in the same experimental area, and all test subjects keep moving synchronously, and the test subjects stay in the outside world for no less than six hours a day; pass YG 136A on weekends every week The evenness test analyzer conducts the evenness test on all the experimental objects;

[0063] Remove the maximum value and minimum value in the test results of each group respectively, and then accumulate the remaining test data results and divide them by 18 to obtain the average value of each group of experimental objects as the representative value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com