Equipment state trend analysis and fault diagnosis method

A technology of trend analysis and fault diagnosis, which is applied in the field of trend analysis and fault diagnosis of industrial equipment, and can solve problems such as prediction and judgment of equipment failure time due to the remaining operating time of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

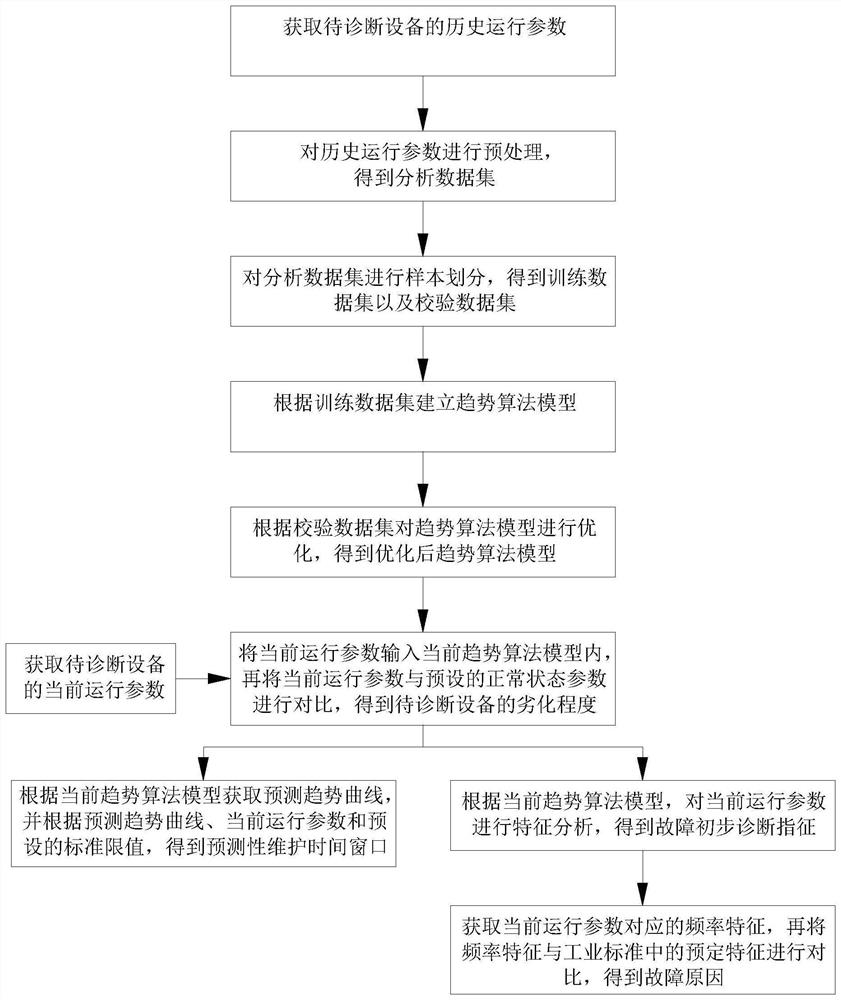

[0038] This embodiment provides a method for equipment status trend analysis and fault diagnosis, including the following steps:

[0039] S1. Obtain historical operating parameters of the equipment to be diagnosed;

[0040] S2. Preprocess the historical operating parameters to obtain the analysis data set; to meet the time domain and frequency domain analysis requirements of the historical operating parameters; it should be noted that the analysis data set is used as a follow-up trend analysis algorithm and / or fault diagnosis algorithm The input parameter set can be set as a temperature risk data set or a vibration analysis data set according to the choice of equipment judgment;

[0041] S3. Establish a trend algorithm model according to the analysis data set;

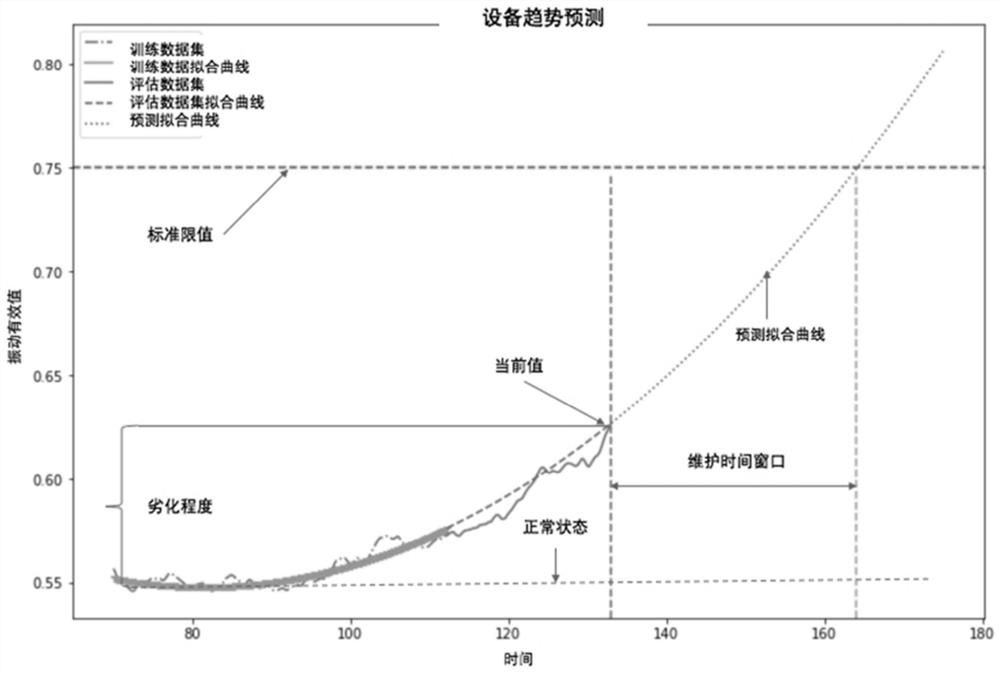

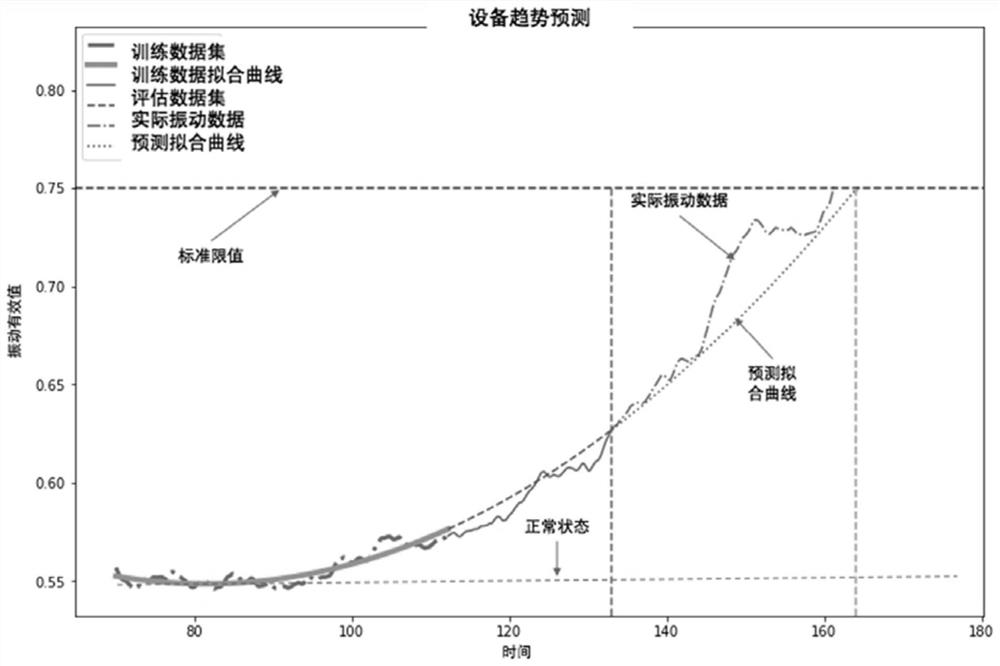

[0042] S4. Obtain the current operating parameters of the equipment to be diagnosed, and input the current operating parameters into the current trend algorithm model, and then compare the current operating parameters...

Embodiment 2

[0050] This embodiment provides a method for equipment status trend analysis and fault diagnosis, such as figure 1 shown, including the following steps:

[0051] S1. Obtain historical operating parameters of the equipment to be diagnosed;

[0052]Specifically, the historical operating parameters include a vibration time-series sequence and a temperature time-series sequence; wherein, the vibration time-series sequence is vibration frequency data with time labels, and the temperature time-series sequence is temperature data with time labels. The selection of the vibration frequency data depends on the difference of the equipment to be diagnosed and the difference of the signal acquisition equipment, and can be selected as vibration displacement signal, vibration velocity signal and / or vibration acceleration signal.

[0053] S2. Preprocess the historical operating parameters to obtain the analysis data set; to meet the time domain and frequency domain analysis requirements of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com