High-breaking miniature circuit breaker

A miniature circuit breaker, high-breaking technology, applied in the direction of circuit breaker components, circuit breaker contacts, protection switch operation/release mechanism, etc., can solve the risk of contact welding, without the ability to quickly connect high-voltage circuits, circuit break Electrical corrosion of contacts and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Below in conjunction with accompanying drawing this embodiment is described in detail:

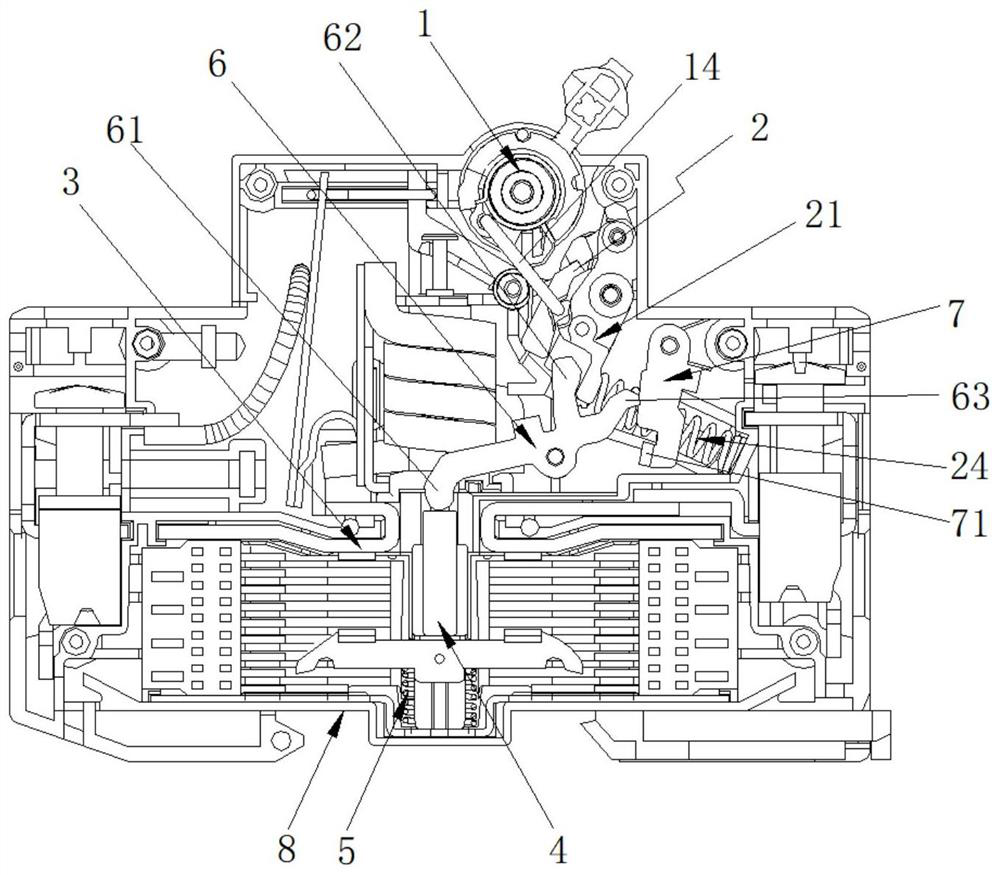

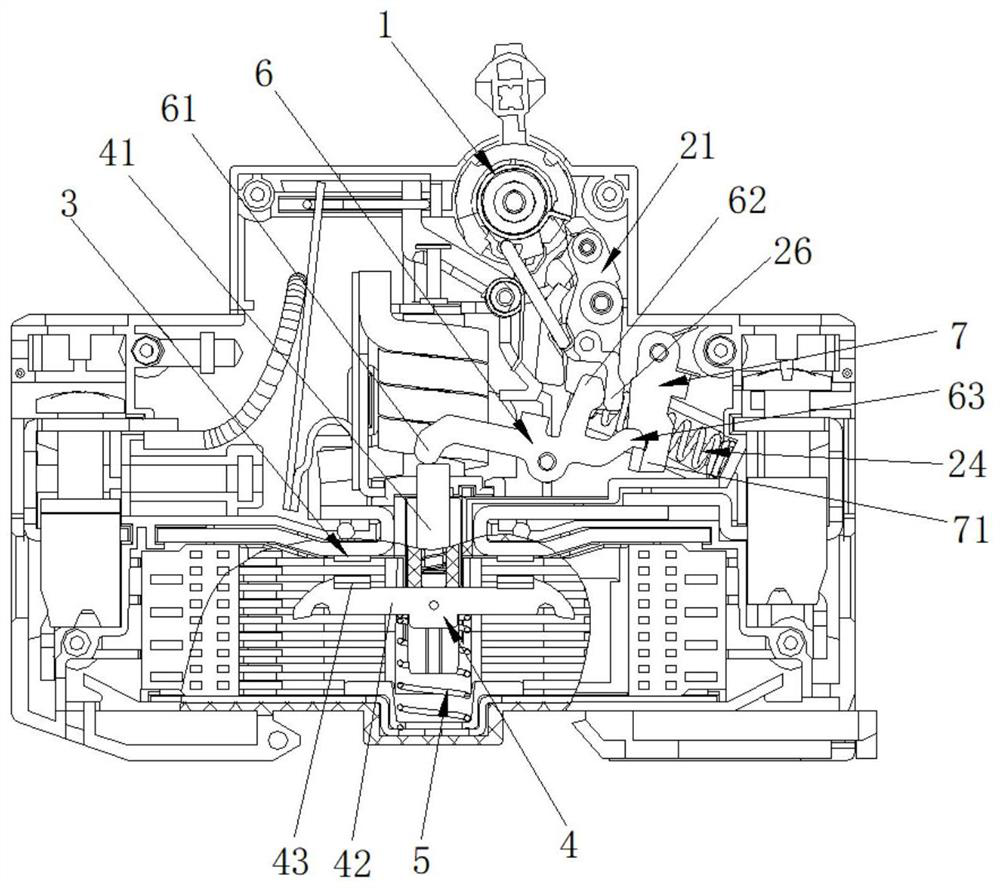

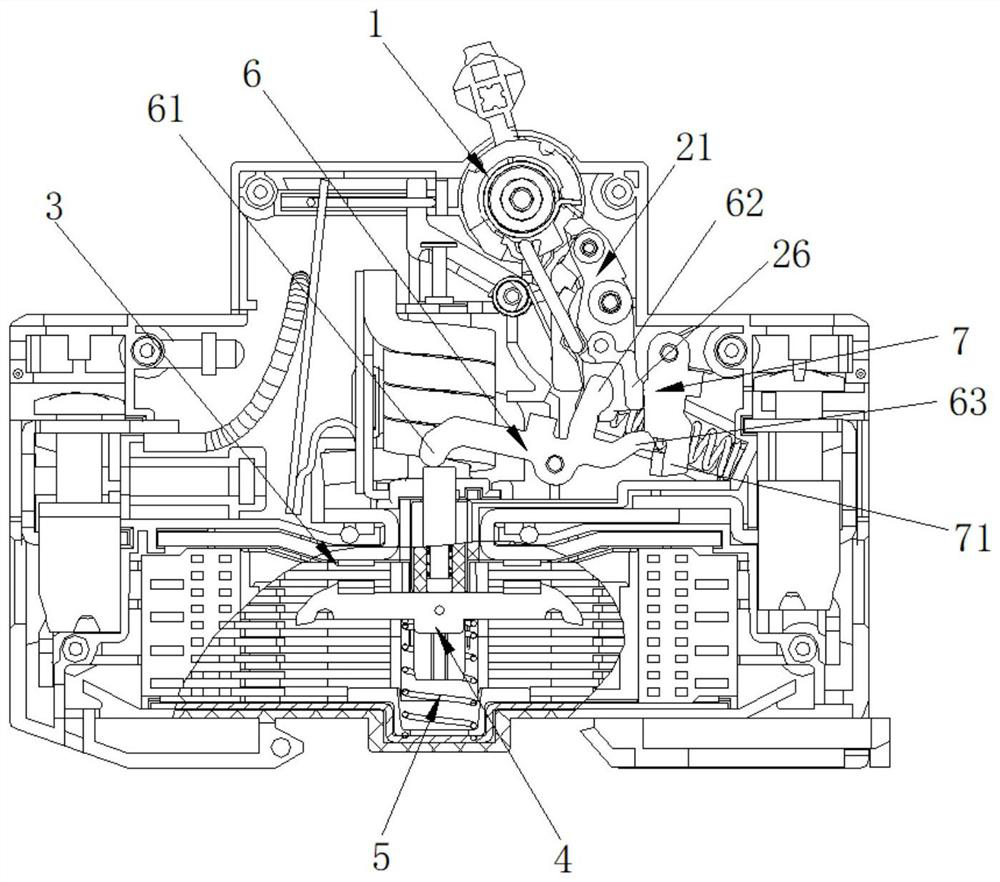

[0046] The present invention provides as Figure 1-9 A high breaking miniature circuit breaker is shown, including:

[0047] The handle structure 1 is rotated and arranged on the shell;

[0048] The tripping assembly 2, which cooperates with the handle structure 1, includes a runner 21 rotatably arranged on the housing. The tripping assembly 2 has a function to drive the runner 21 to rotate forward when the handle structure closes and moves. Closing state, and the opening state in which the runner 21 is driven to reversely rotate when the handle structure 1 is in the opening movement;

[0049] The contact structure includes a static contact 3 fixed to the housing, a moving contact part 4 which is movably arranged on the housing relative to the static contact, and a moving contact part 4 arranged between the moving contact part 4 and the The elastic member 5 between the housings, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com