Tea leaf rolling machine and continuous tea leaf rolling unit

A kneading machine and tea technology, which is applied in the field of tea processing equipment, can solve the problems of unsatisfactory effect and low production efficiency of kneading machines, and achieve the effects of avoiding bad wiring, stable movement, and improving kneading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

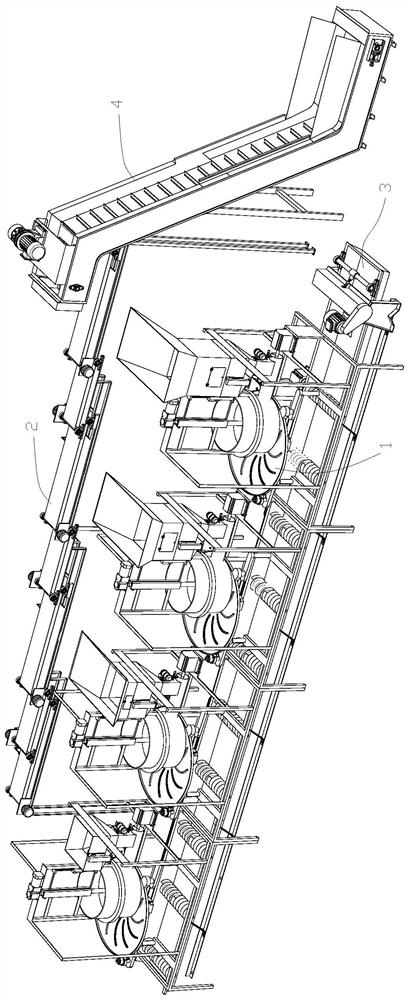

[0066] A tea continuous rolling unit

[0067] refer to figure 1 , the present embodiment proposes a tea continuous rolling unit, including a feed unit 2, a discharge unit 3, a general controller and a plurality of tea rolling machines 1.

[0068] The feeding unit 2 is used to supplement materials, namely tea leaves, to each tea rolling machine 1; the tea leaves rolled by each tea rolling machine 1 are discharged through the discharge unit 3.

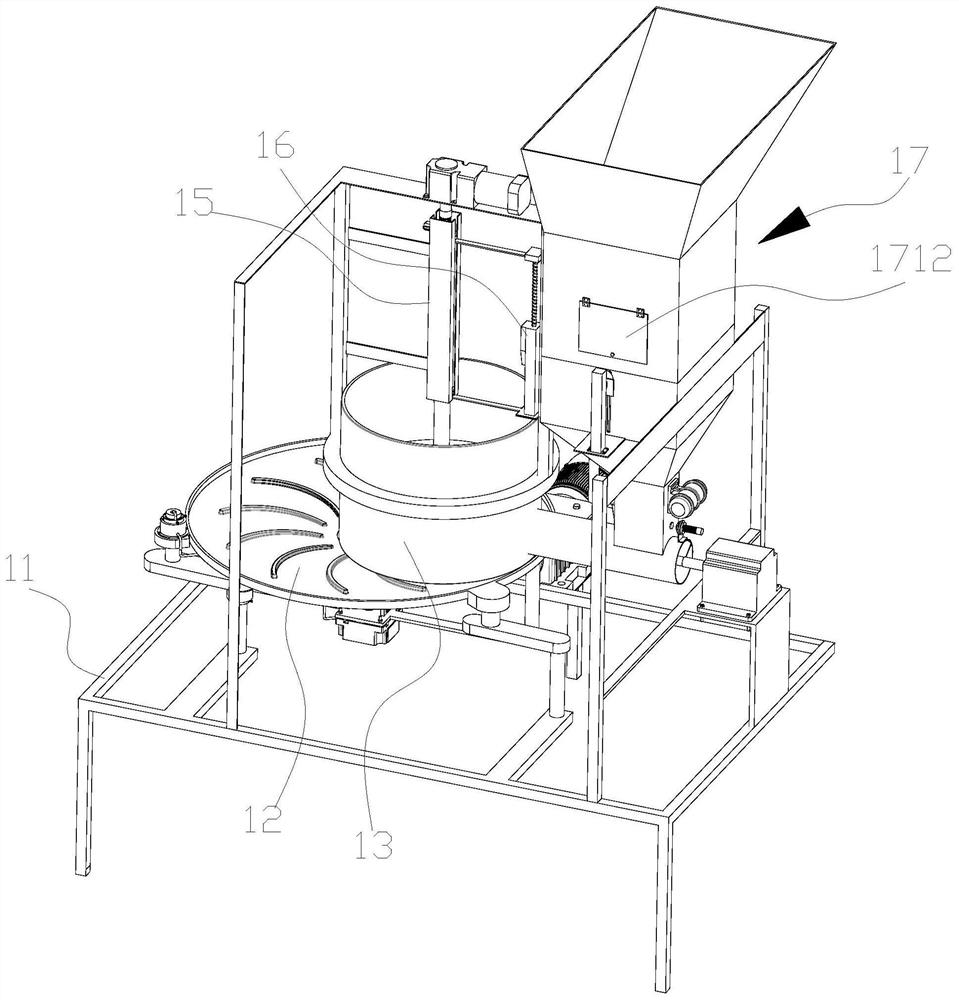

[0069] tea rolling machine

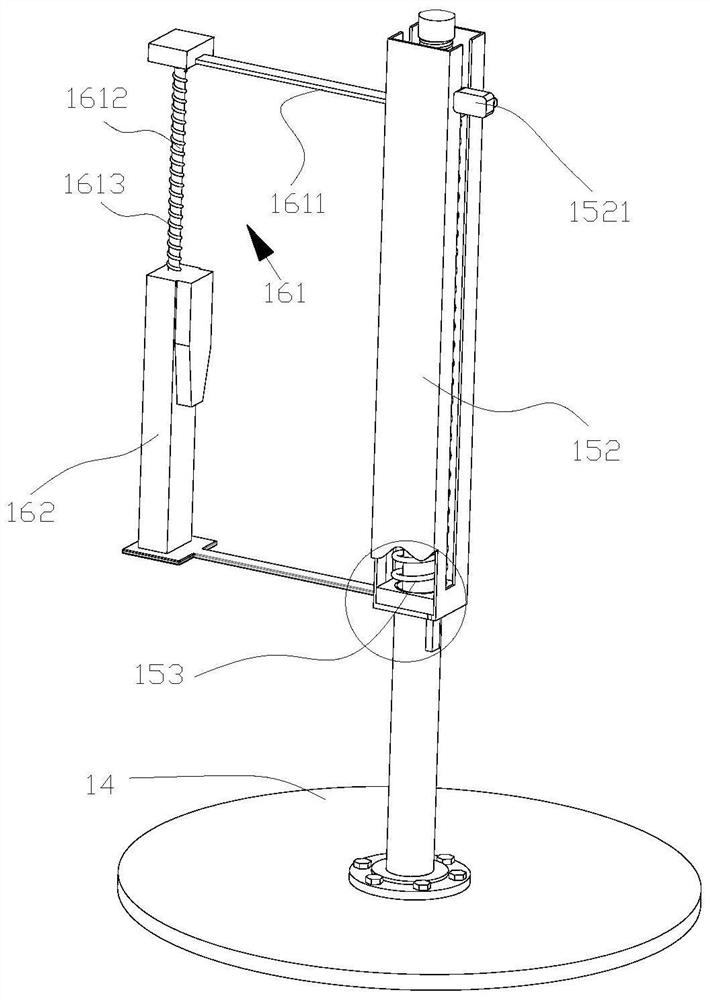

[0070] A tea rolling machine proposed in this embodiment includes: a frame 11 , a kneading plate 12 , a kneading barrel 13 , a kneading barrel cover 14 , a pressurizing part 15 , a pressure detecting part, a controller and a feeding part 17 .

[0071] Kneading pan 12 and kneading barrel 13 are all arranged on the frame 11, kneading pan 12 is connected with a kneading pan driving part for driving it to carry out plane movement in the horizontal direction, kneading pan 13 is set statically and is positioned a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com