Operation positioning device with high precision and positioning method thereof

A positioning device and surgical technology, which is applied in the direction of surgical instrument support, can solve problems such as difficult placement and winding, and achieve the effects of reducing pressure, reducing wear, and ensuring stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

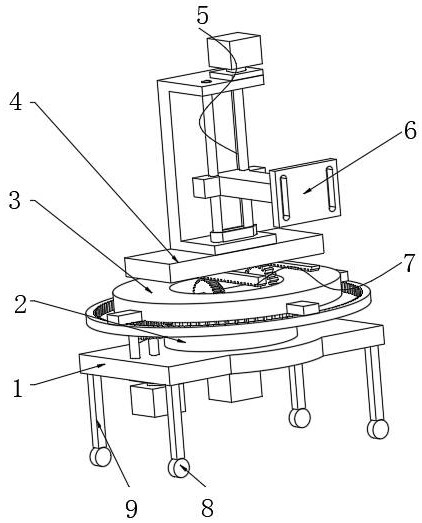

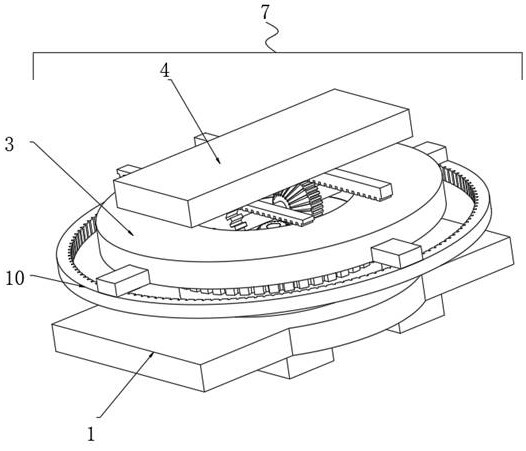

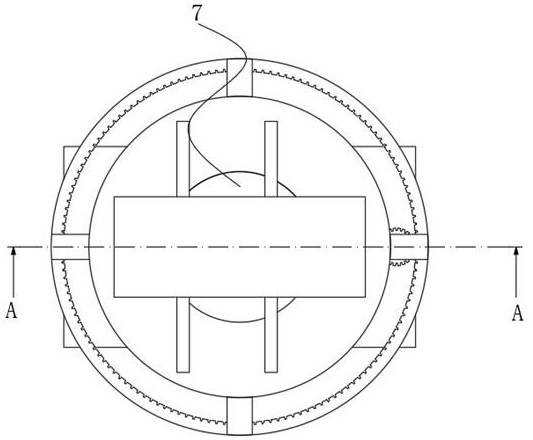

[0040] A surgical positioning device with high precision, such as Figure 1-5As shown, it includes a fixed base 1, the top outer wall of the fixed base 1 is connected with a rotating platform 3 through a rotating drum 2, and the top of the rotating platform 3 is slidably connected with a linear moving platform 4 through a linear slide rail, and the linear moving platform 4 The top of the platform 4 is connected with a surgical instrument mounting seat 6 through a lifting mechanism 5, and the fixed base 1, the rotating platform 3 and the linear moving platform 4 are cooperated through a rotation-translation integrated mechanism 7, and the rotation-translation integrated mechanism 7 includes The intermeshed straight bevel integrated gear 14 and rack two 15, the intermeshed external ring gear 16 and the rotating drive gear 20, the said straight bevel integrated gear 14 is connected to the inner side of the rotary platform 3 through the rotation of the shaft one 13, The second rac...

Embodiment 2

[0047] A surgical positioning device with high precision, such as figure 1 , 6 As shown, in order to solve the lifting problem; this embodiment makes the following improvements on the basis of Embodiment 1: the lifting mechanism 5 includes a lifting frame 26 and a lifting platform 29, and the inner wall of the lifting frame 26 is rotatably connected with two lead screws 28, two lead screws 28 are connected to the inner wall of the lifting platform 29 by threads, and the surgical instrument mounting base 6 is fixed on the outer wall of the lifting platform 29 by bolts, and the top outer wall of one of the leading screws 28 is connected by a coupling The device is connected with a lifting motor 27, and the lifting motor 27 is fixed on the top outer wall of the lifting frame 26 by bolts, and the two leading screws 28 establish transmission cooperation through a synchronous belt 30.

[0048] When this embodiment is in use, when the lifting motor 27 starts, it can drive the screw ...

Embodiment 3

[0050] A method for positioning a surgical positioning device with high precision, the specific steps are as follows:

[0051] S1: fix the surgical instrument on the surgical instrument mount 6;

[0052] S2: After moving the device to the operating room, first start the lifting motor 27 to adjust the approximate height of the surgical instrument mounting seat 6;

[0053] S3: After the height is determined, start the rotating drive motor 22 to adjust the approximate angle of the surgical instrument mounting seat 6;

[0054] S4: Then start the translation drive motor 24 to extend the surgical instrument to the lesion of the patient to be operated on;

[0055] S5: Repeat S2-S4 to complete the final height, angle and distance adjustment to complete the positioning.

[0056] Working principle: when the translation drive motor 24 starts, it drives the bevel gear 25 to rotate through the translation drive shaft 23, thereby driving the straight-cone integrated gear 14 to rotate thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com