Waste water removal device for machining and using method

A mechanical processing and waste technology, applied in the field of mechanical processing, can solve the problems of incapable of sorting and recycling waste liquid and waste, reducing processing efficiency, unable to realize the synchronization of feeding and discharging processes, etc., to save processing time and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

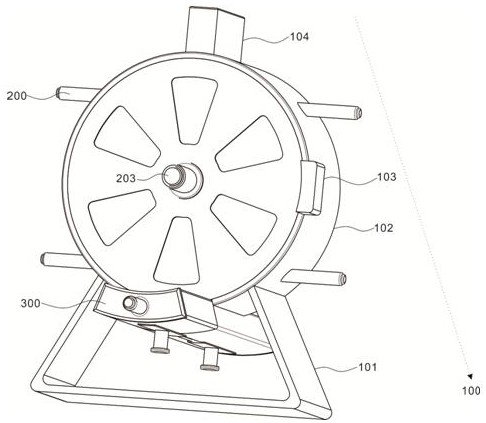

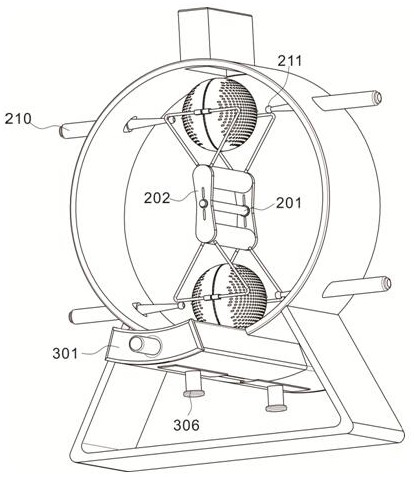

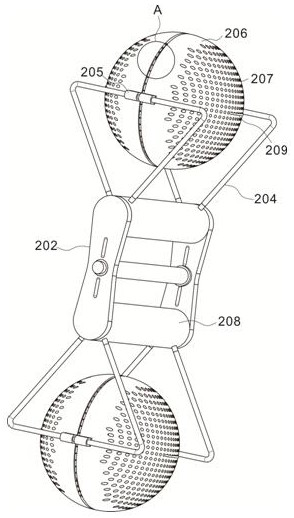

[0028] Example 1: Please refer to figure 1 and figure 2 , the present invention provides a waste water removal device for mechanical processing, including a housing assembly 100, including a support frame 101, the top of the support frame 101 is fixedly connected to the shell 102, the top of the shell 102 is provided with a feed channel 104, and the surface of the shell 102 is respectively A feed port and a discharge port are provided, and a control box 103 is provided on the side wall of the casing 102; the water removal assembly 200 includes a rotating shaft 201 that is movably inserted into the inner cavity of the casing 102, and the end of the rotating shaft 201 runs through the casing 102 and is connected to the drive The output end of the motor 203 is connected to the collection assembly 300 , and the collection assembly 300 is arranged at the bottom of the housing 102 .

[0029] The two ends of the rotating shaft 201 are fixedly connected with the movable plate 202, a...

Embodiment 2

[0034] Example 2: Please refer to figure 2 and Figure 5 The collection assembly 300 includes a guide frame 301 fixed on the bottom of the casing 102 close to the discharge port. The inner cavity of the guide frame 301 is symmetrically provided with a slidable collection box 302 and a water collection box 303. Between the collection box 302 and the water collection box 303 They are linked by connecting rod 304, and the collection box 302 is controlled to move in the guide frame 301 by the push cylinder 305. When the dome cover 206 is running at high speed, the push cylinder 305 drives the water collection box 303 to move to the discharge of the shell 102. Below the outlet, the filtered liquid is collected, and when the waste is discharged, the collection box 302 is driven to move to the bottom of the outlet, so that the water removal operation is carried out in an orderly manner. The bottom of the collection box 302 and the water collection box 303 are equipped with outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com