Rapid repairing method for rocket sled sliding rail fastener

A repair method and technology for rocket skids are applied in the field of quick repair of rocket skid slide rail fasteners, which can solve the problems of high construction input cost and long construction time for bolt replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

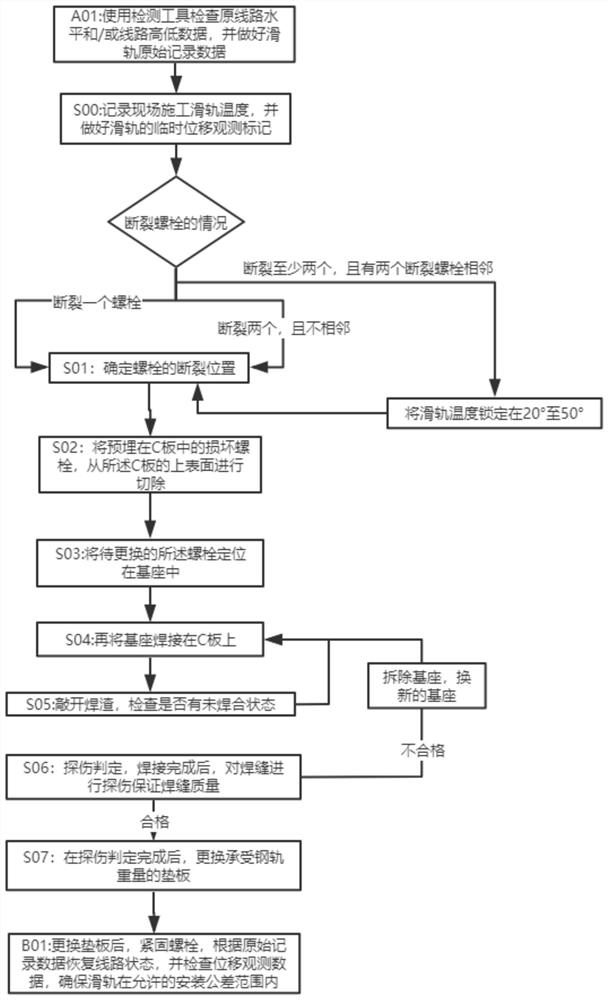

[0036] S00: Record the temperature of the on-site construction slide rail, and make a temporary displacement observation mark of the slide rail;

[0037] If there is only one broken bolt, directly perform step S01;

[0038] S01: determine the bolt fracture location;

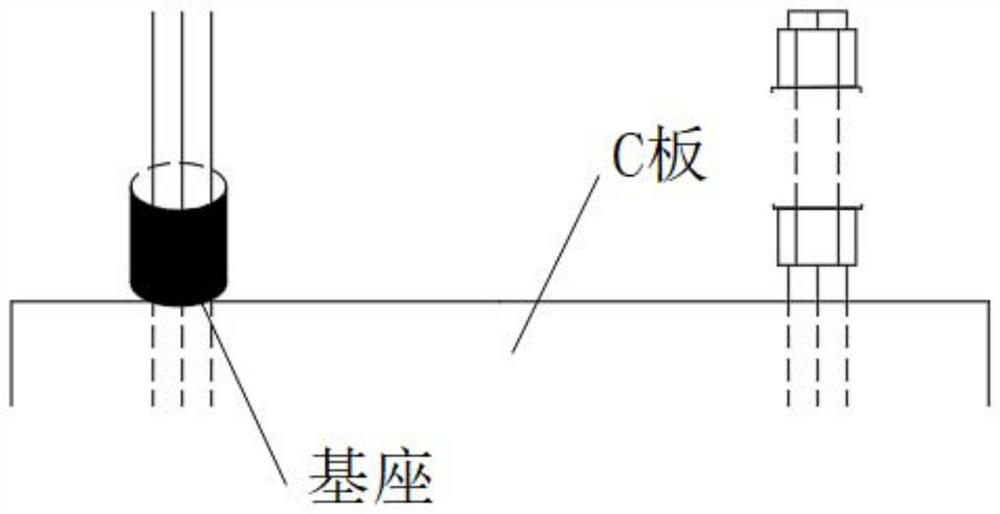

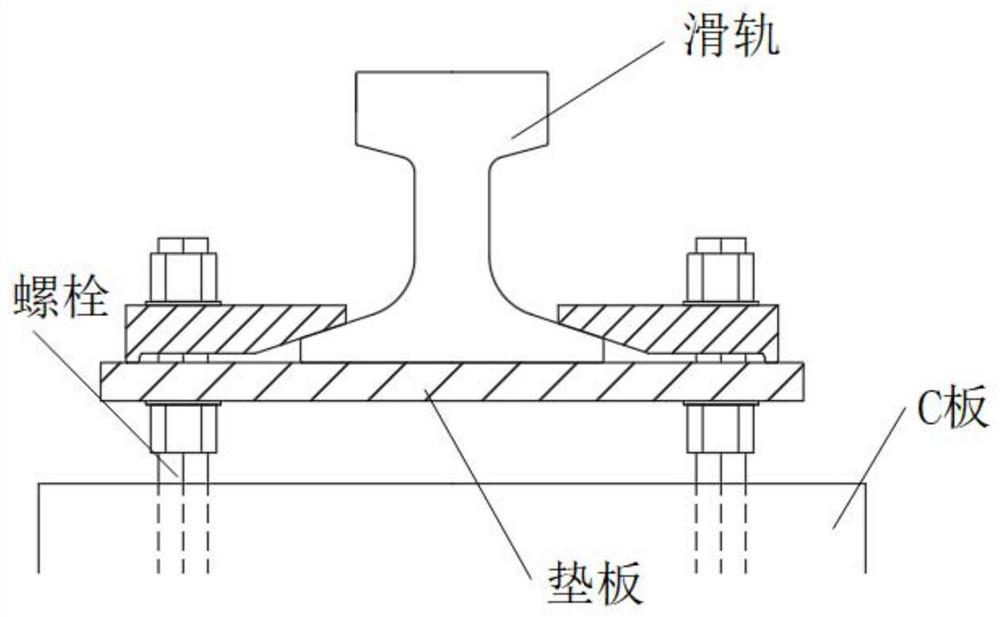

[0039] S02: Removing the damaged bolts embedded in the C-plate from the upper surface of the C-plate;

[0040] S03: positioning the bolt to be replaced in the base;

[0041] S04: Solder the base on the C board;

[0042] S05: Knock off the welding slag, check whether there is an unwelded state, if there is an unwelded state, return to S04.

[0043] If there is only one broken bolt, and the broken bolt is a point damage, it is only necessary to make a temporary displacement observation mark of the slide rail to judge whether the slide rail has shifted during the bolt replacement process.

Embodiment 2

[0045] S00': record the temperature of the on-site construction slide rail, and make a temporary displacement observation mark of the slide rail;

[0046] If there are at least two broken bolts, and the two bolts are not adjacent, directly execute step S01;

[0047] S01: determine the bolt fracture location;

[0048] S02: Removing the damaged bolts embedded in the C-plate from the upper surface of the C-plate;

[0049] S03: positioning the bolt to be replaced in the base;

[0050] S04: Solder the base on the C board;

[0051] S05: Knock off the welding slag, check whether there is an unwelded state, if there is an unwelded state, return to S04.

[0052]If there are at least two broken bolts, and there are normally used bolts between every two broken bolts, it means that the binding force of the bolts on the slide rail has not been greatly affected, and each broken bolt belongs to point damage, and only It is necessary to make a temporary displacement observation mark of th...

Embodiment 3

[0054] S00": If there are at least two broken bolts and the two bolts are adjacent, the temperature of the slide rail is locked at 20° to 50°;

[0055] S01: determine the bolt fracture location;

[0056] S02: Removing the damaged bolts embedded in the C-plate from the upper surface of the C-plate;

[0057] S03: positioning the bolt to be replaced in the base;

[0058] S04: Solder the base on the C board;

[0059] S05: Knock off the welding slag, check whether there is an unwelded state, if there is an unwelded state, return to S04.

[0060] Once two adjacent bolts are broken, a large amount of heat will be generated when the base is welded to the C plate, and this heat will cause the internal stress of the rail to be unbalanced, thereby causing a small range of deflection of the rail. This deviation will cause the horizontal or vertical direction of the slide rail to deviate, which in turn makes the rocket sled slide rail experiment unable to run at high speed. On the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com