Injection mold for dropper

A technology of injection molds and droppers, which is applied to household appliances, other household appliances, applications, etc., can solve the problems of reduced work efficiency, low service life of blades, and low work efficiency, so as to reduce work intensity, improve service life, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

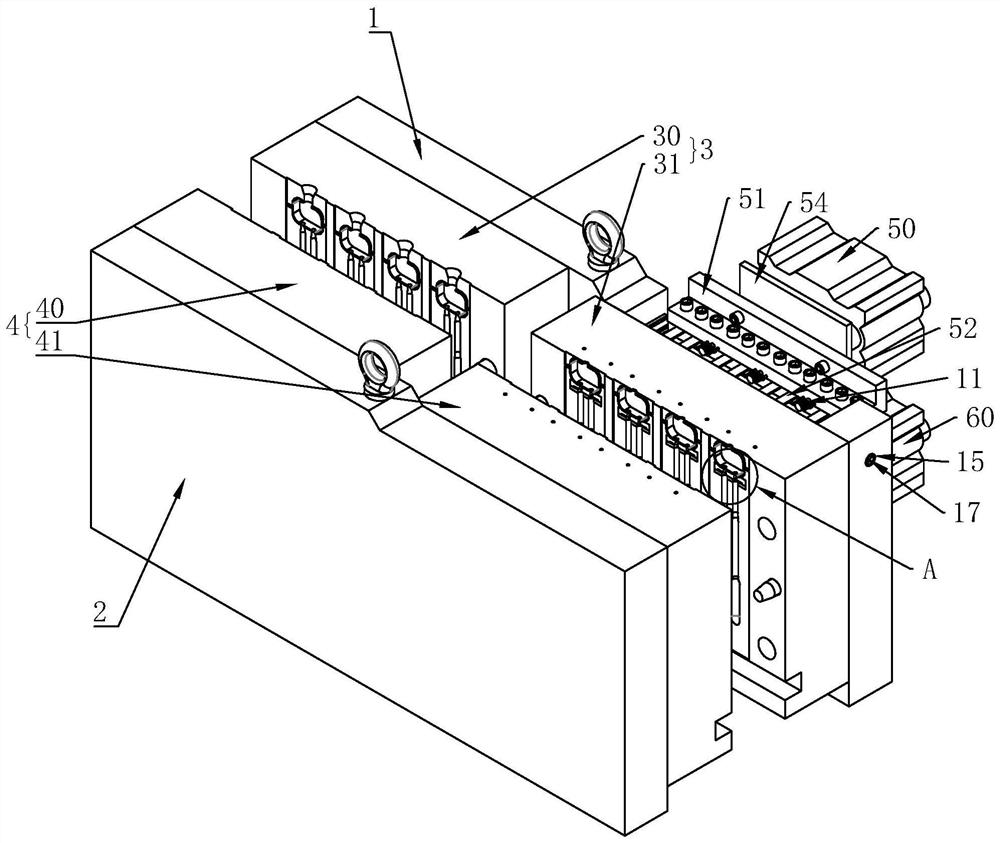

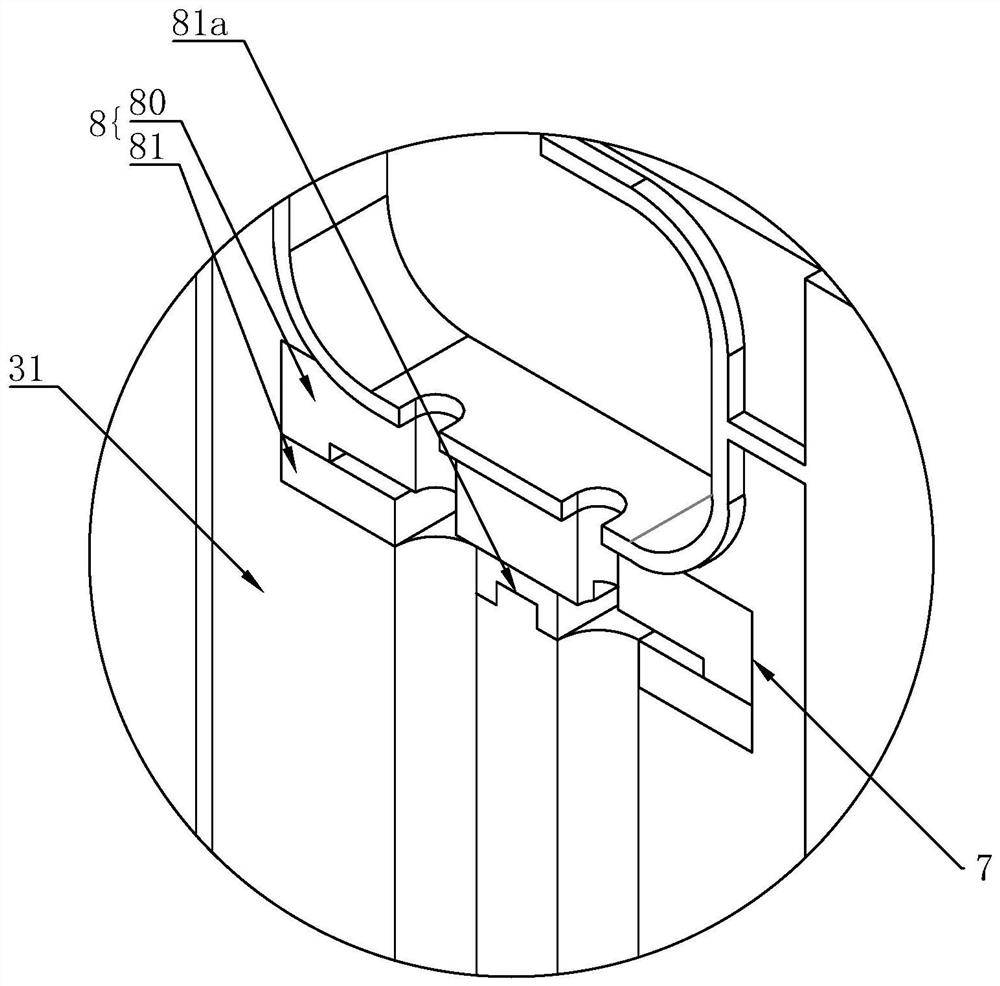

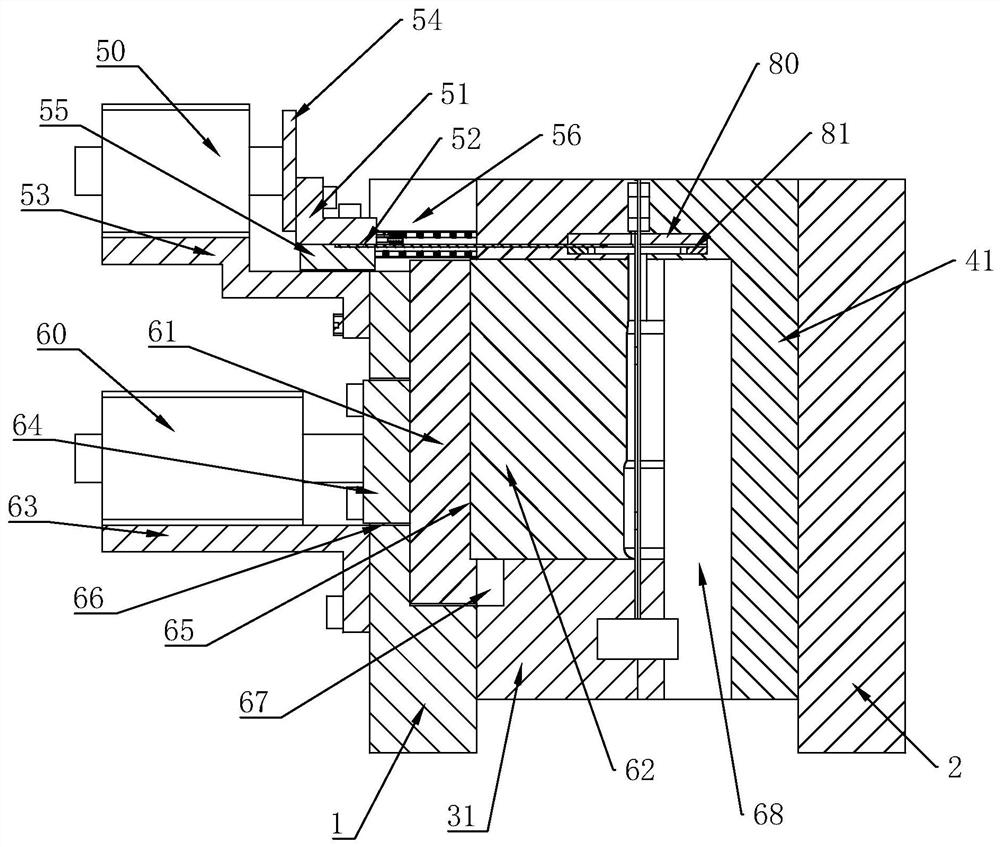

[0029] Combine below Figure 1 to Figure 9 The present invention is further described with specific embodiment:

[0030] An injection mold for a dropper, comprising a front mold frame 1, a rear mold frame 2, a front template 3 and a rear template 4, the front template 3 includes a front molding template 30 and a front finished template 31, and the rear template 4 includes a rear template Forming template 40 and back finished template 41, described front molding template 30 is corresponding to back molding template 40, and front finished template 31 is corresponding to rear finished template 41, and described front formwork 1 and is positioned at front finished template 31 places There is a push knife structure 5 and a push tube structure 6, and the above-mentioned front forming template 30, post forming template 40, front finished template 31 and rear finished template 41, and the front formwork 1 and the rear formwork 2 are preferably installed and fixed by bolts .

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com