A tube-type vertical ejection type ejection UAV, its ejection system and its implementation method

A UAV and tubular technology, applied in the field of UAV, can solve the problems of task load space squeeze, poor deployment flexibility, harsh take-off conditions, etc., and achieve high ejection efficiency, fast deployment speed, excellent functions and structural layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

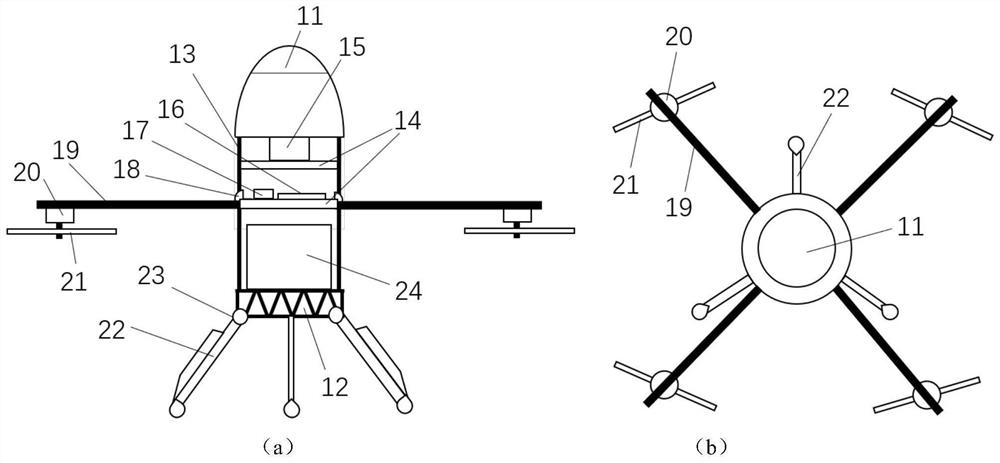

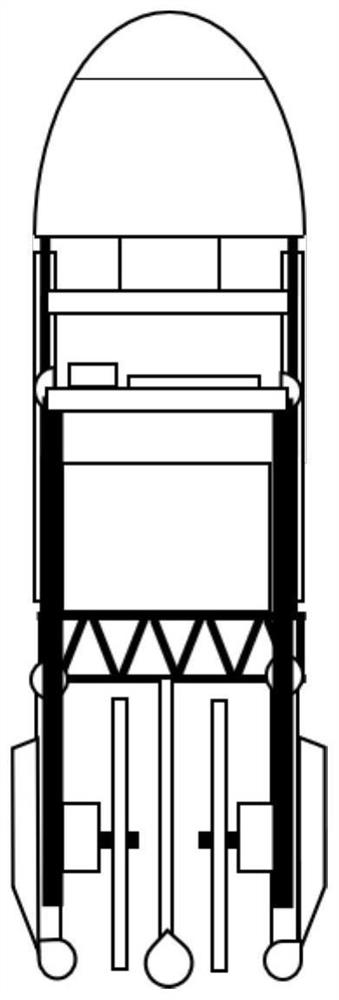

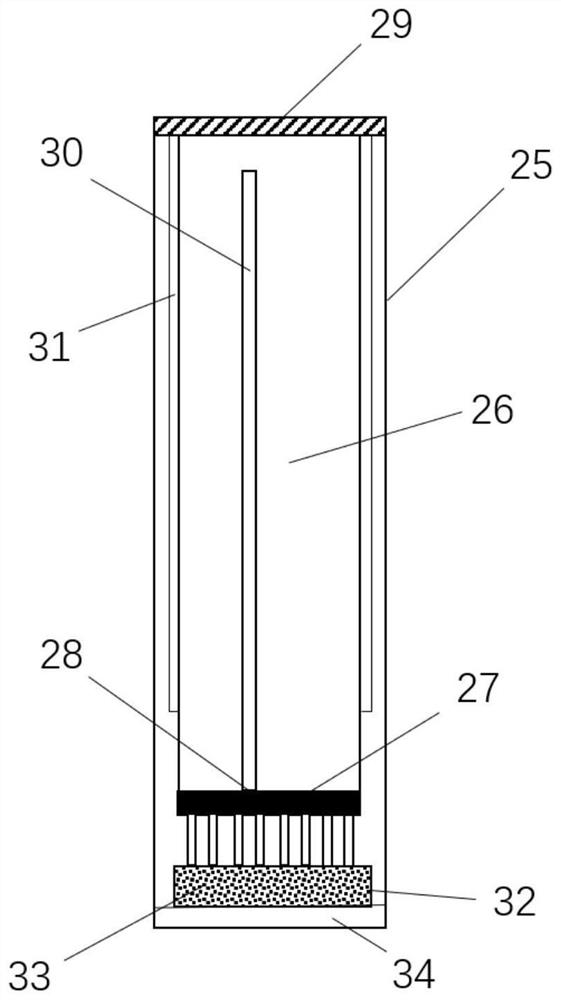

[0039] Such as figure 1 As shown, the tube-type vertical ejection ejection UAV and its ejection system of this embodiment are mounted on the carrier platform, including: ejection UAV and ejection system; wherein, the ejection system is built-in and installed in the carrier platform, ejection The ejection port of the system is located on the top of the carrier platform and points vertically directly above the carrier platform, which can realize the function of ejecting multiple ejection UAVs; the ejection UAV is installed in the ejection system, and the ejection system can be used to quickly complete the take-off Take off into the air to realize rapid deployment on a highly dynamic battlefield and quickly execute tasks; when the carrier platform reaches the designated mission area, the operator controls the ejection system to quickly eject ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com