Catalyst and method for producing high-octane gasoline from coal-based light oil

A high-octane gasoline and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as unseen utilization, improve acid function and pore structure, improve production efficiency, The effect of reducing the amount of B acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

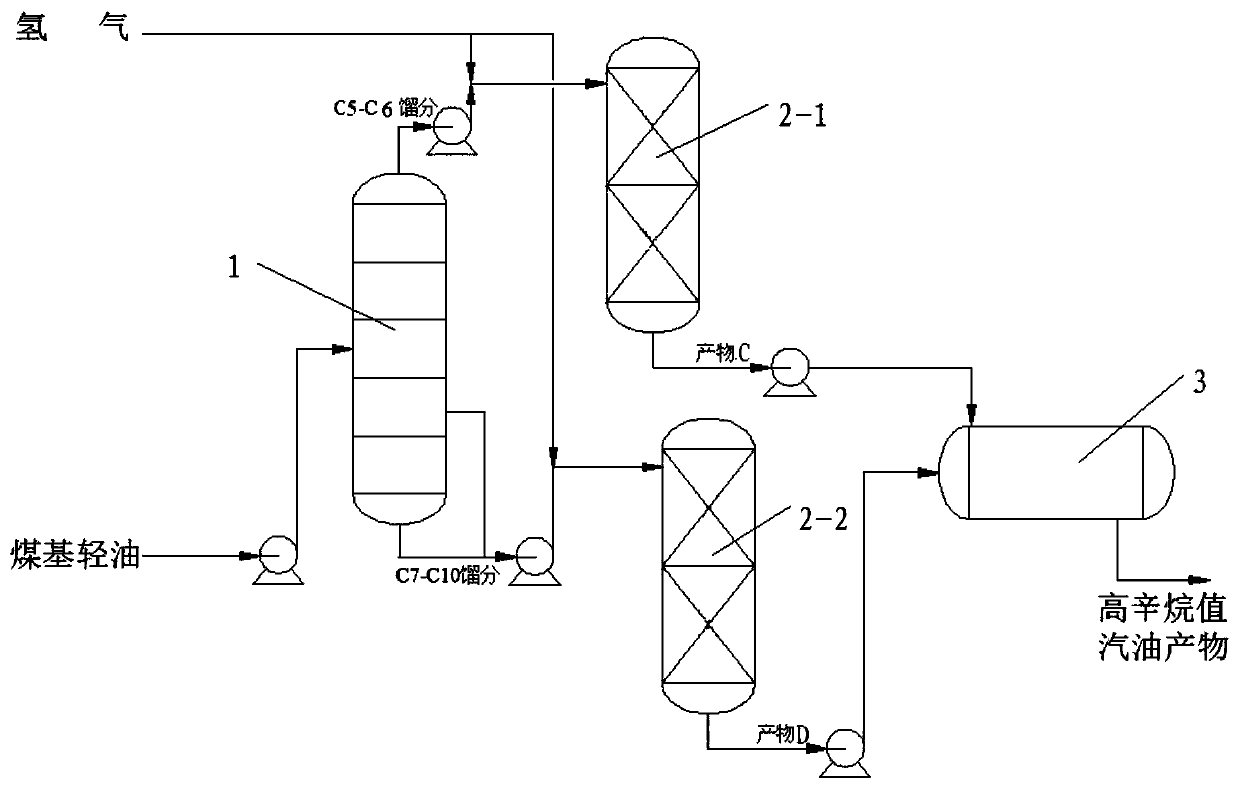

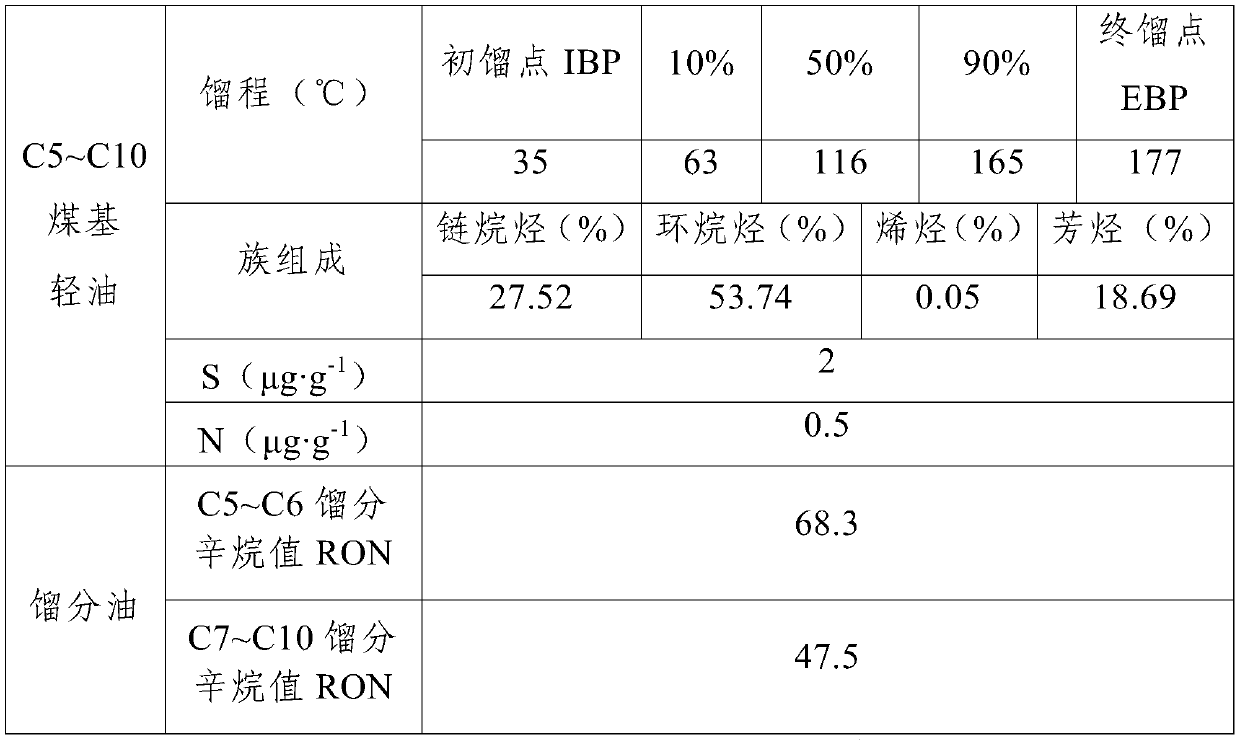

[0039] The catalyst of this embodiment includes catalyst A and catalyst B. The catalyst A includes a carrier A1 and a noble metal component A2 and a metal oxide component loaded on the carrier A1. The carrier A1 is composed of a hydrogen-type high-silicon Mor molecular sieve, Prepared by hydrogen-type Beta molecular sieve and pseudo-boehmite, SiO in the hydrogen-type high-silicon Mor molecular sieve 2 and Al 2 o 3 The molar ratio is 25, Al in the hydrogen type high silicon Mor molecular sieve, hydrogen type Beta molecular sieve and pseudo-boehmite 2 o 3 The mass ratio is 25:50:25, the precious metal component A2 is Pt, the mass of the Pt is 0.25% of the mass of the carrier A1, the metal oxide component is NiO, and the mass of the NiO is 3.5% of the mass of the carrier A1;

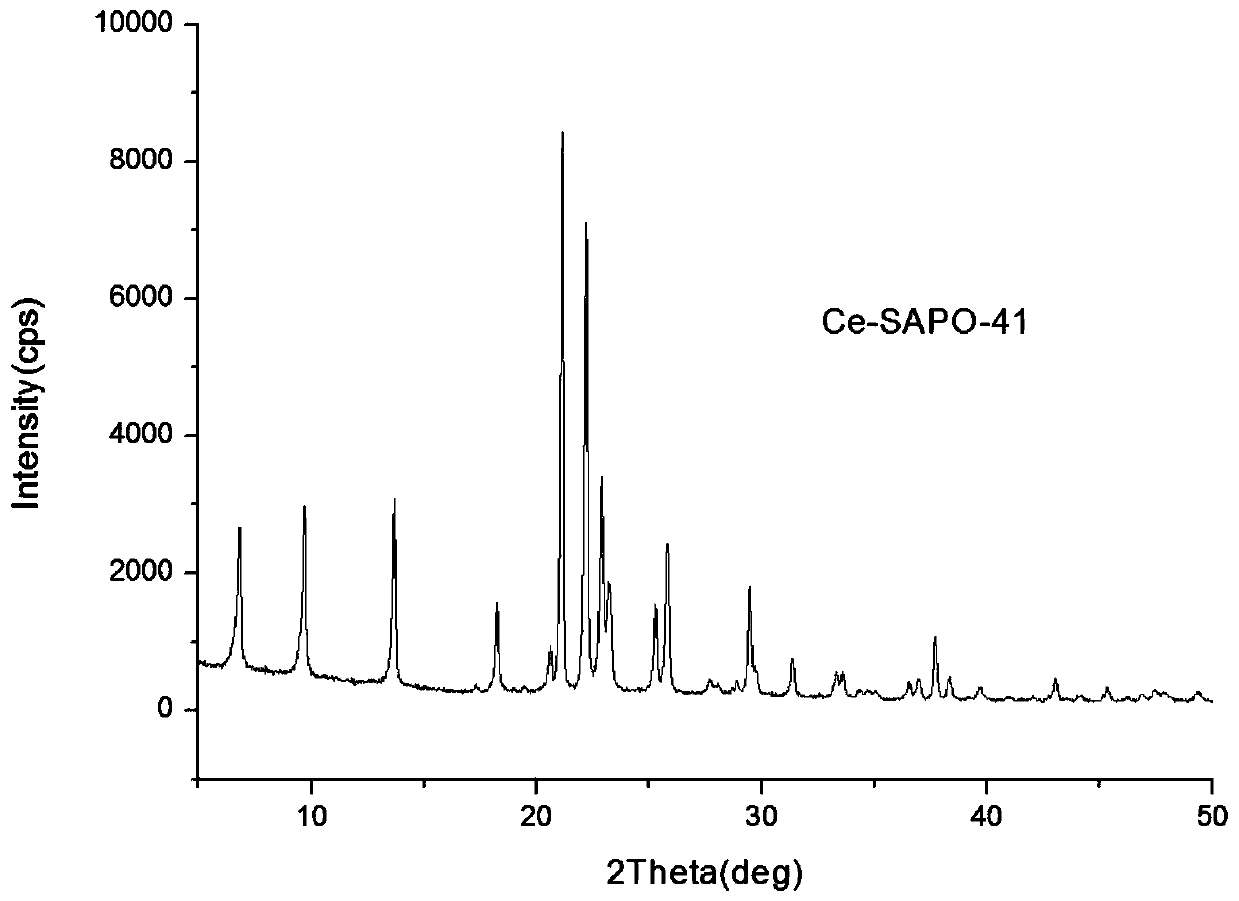

[0040] Catalyst B in this embodiment includes a carrier B1 and a noble metal component B2 loaded on the carrier B1, the carrier B1 is prepared from Ce-SAPO-41 molecular sieve and pseudoboehmite, and the...

Embodiment 2

[0050] The catalyst of this embodiment includes catalyst A and catalyst B. The catalyst A includes a carrier A1 and a noble metal component A2 and a metal oxide component loaded on the carrier A1. The carrier A1 is composed of a hydrogen-type high-silicon Mor molecular sieve, Prepared by hydrogen-type Beta molecular sieve and pseudo-boehmite, SiO in the hydrogen-type high-silicon Mor molecular sieve 2 and Al 2 o 3 The molar ratio is 28, Al in the hydrogen type high silicon Mor molecular sieve, hydrogen type Beta molecular sieve and pseudo-boehmite 2 o 3 The mass ratio is 30:45:25, the precious metal component A2 is Pt, the mass of the Pt is 0.35% of the mass of the carrier A1, the metal oxide component is NiO, and the mass of the NiO is 4.0% of the mass of the carrier A1;

[0051] Catalyst B in this embodiment includes a carrier B1 and a noble metal component B2 loaded on the carrier B1, the carrier B1 is prepared from Ce-SAPO-41 molecular sieve and pseudoboehmite, and the...

Embodiment 3

[0061] The catalyst of this embodiment includes catalyst A and catalyst B. The catalyst A includes a carrier A1 and a noble metal component A2 and a metal oxide component loaded on the carrier A1. The carrier A1 is composed of a hydrogen-type high-silicon Mor molecular sieve, Prepared by hydrogen-type Beta molecular sieve and pseudo-boehmite, SiO in the hydrogen-type high-silicon Mor molecular sieve 2 and Al 2 o 3 The molar ratio is 30, Al in the hydrogen type high silicon Mor molecular sieve, hydrogen type Beta molecular sieve and pseudo-boehmite 2 o 3 The mass ratio is 30:50:20, the precious metal component A2 is Pt, the mass of the Pt is 0.35% of the mass of the carrier A1, the metal oxide component is NiO, and the mass of the NiO is 4.0% of the mass of the carrier A1;

[0062] Catalyst B in this embodiment includes a carrier B1 and a noble metal component B2 loaded on the carrier B1, the carrier B1 is prepared from Ce-SAPO-41 molecular sieve and pseudoboehmite, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com