Modularized serial inverter in power supply of medium-frequency induction furnace

An induction furnace, a modular technology, is applied in the conversion equipment for intermediate conversion to DC, and the conversion of irreversible DC power input into AC power output, etc., which can solve the problems of failure to guarantee the success rate of starting, failure to maintain full power state, The problems of low electric efficiency of the induction furnace achieve the effect of convenient daily control and maintenance, rationalization of assembly space, and clear functional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical solution of the present invention, the following will be described in detail through specific embodiments in conjunction with the accompanying drawings:

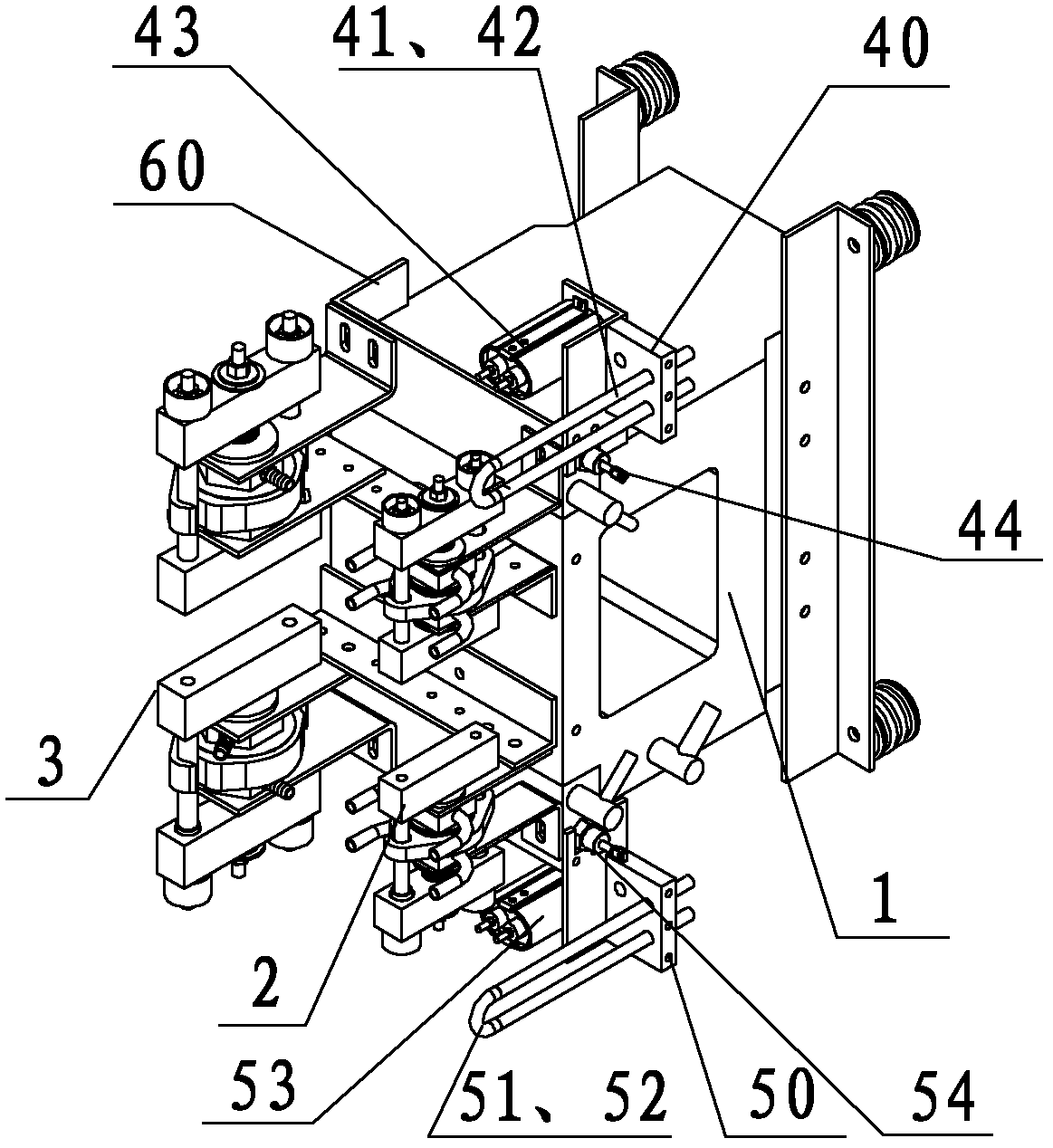

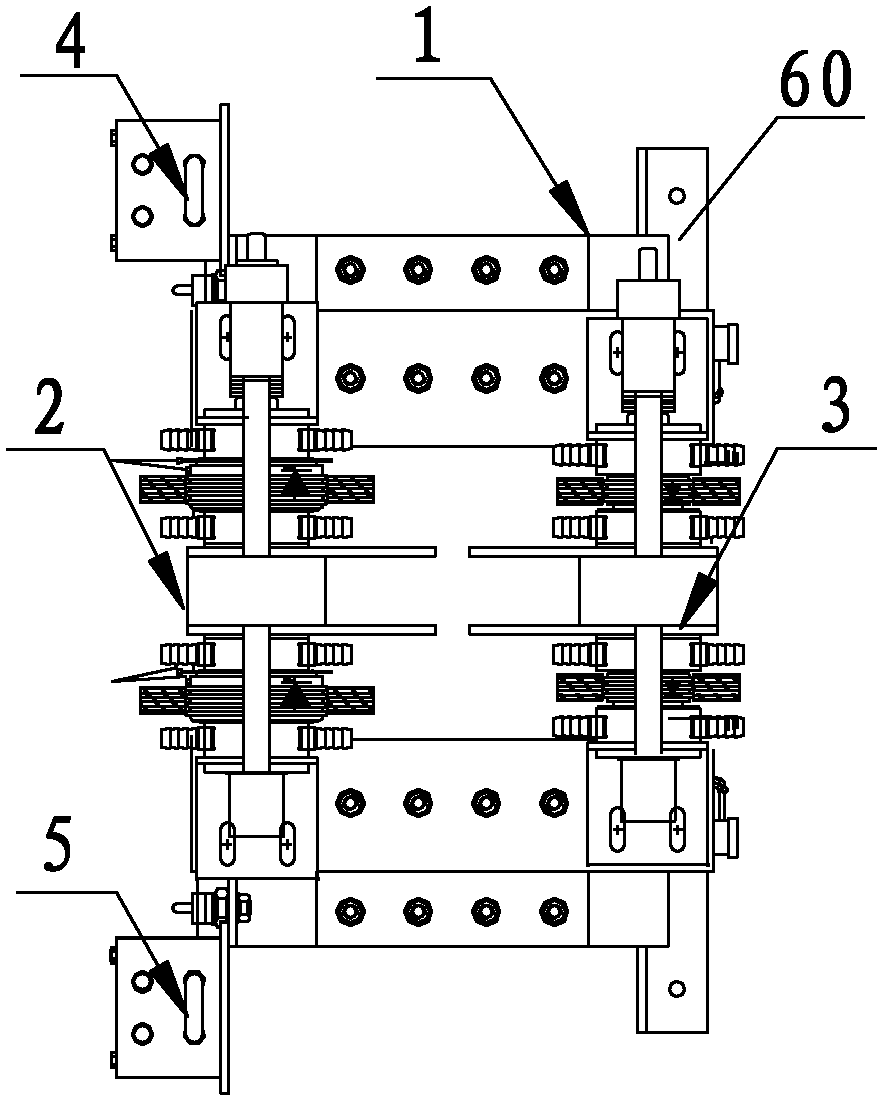

[0022] see Figure 1 to Figure 5 , a series inverter in a modular intermediate frequency induction furnace power supply of the present invention, including an inverter reactor assembly 1, a thyristor assembly 2, a diode assembly 3 and two resistance-capacitance absorption circuit assemblies 4 , 5. The inverter reactor assembly 1 , the thyristor assembly 2 , the diode assembly 3 , and the two RC absorption circuit assemblies are all integrated on an independent frame 60 .

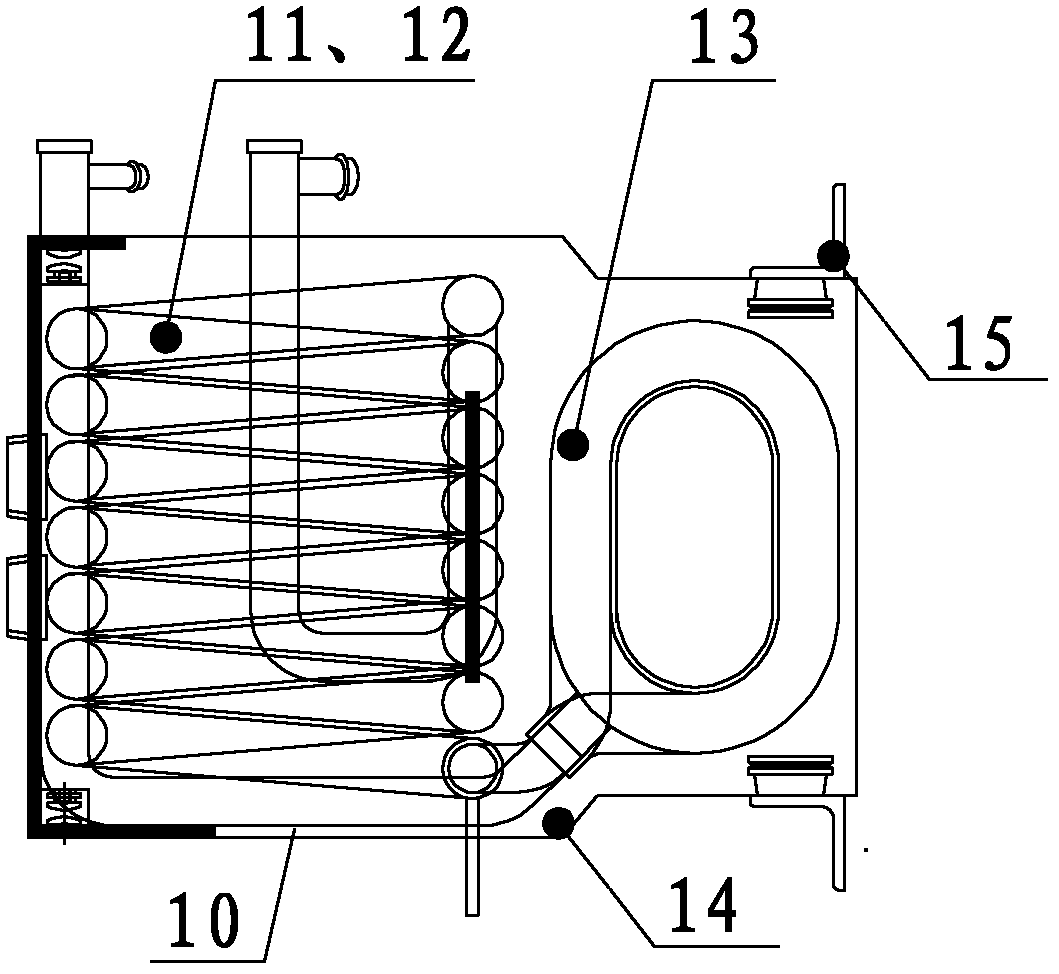

[0023] The inverter reactor assembly 1 includes first and second choke coils and an overvoltage protection coil, the first and second choke coils 11, 12 and an overvoltage protection coil 13 are encapsulated in a casing 10 by polyurethane 14 Its excellent impact resistance, water resistance, heat resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com