Anti-radiation aerogel composite coiled material and application method thereof in wall

An aerogel and composite roll technology, which is used in building thermal insulation materials, buildings, building components, etc., can solve the problems of poor thermal insulation effect of inorganic materials, the need to be thick, and the difficulty of organic materials to meet the needs of building fire protection. Reduce material consumption, reduce crowding, small self-weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

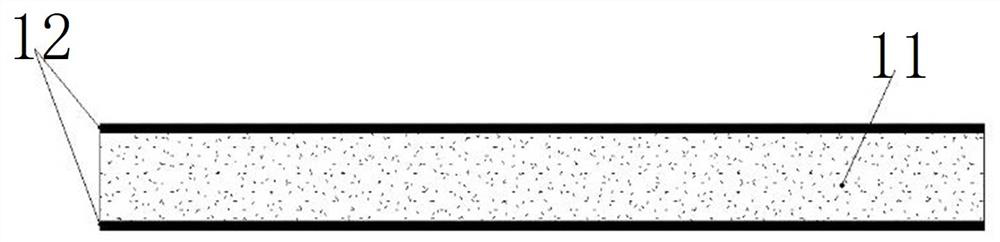

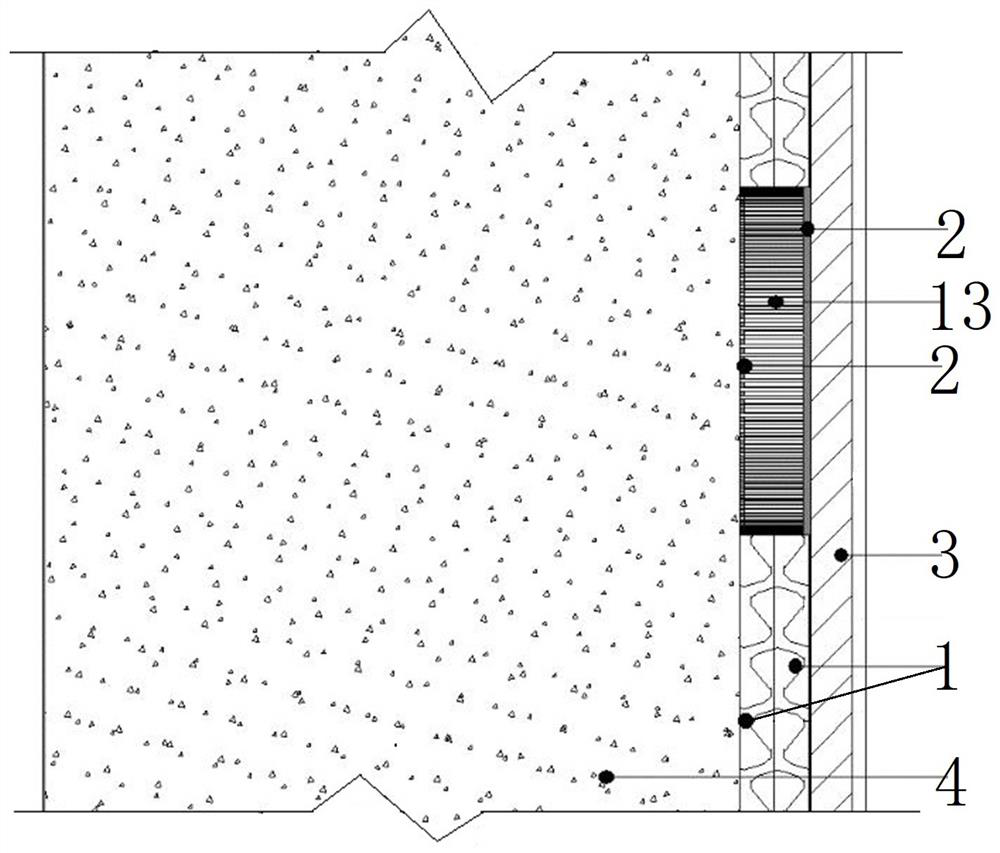

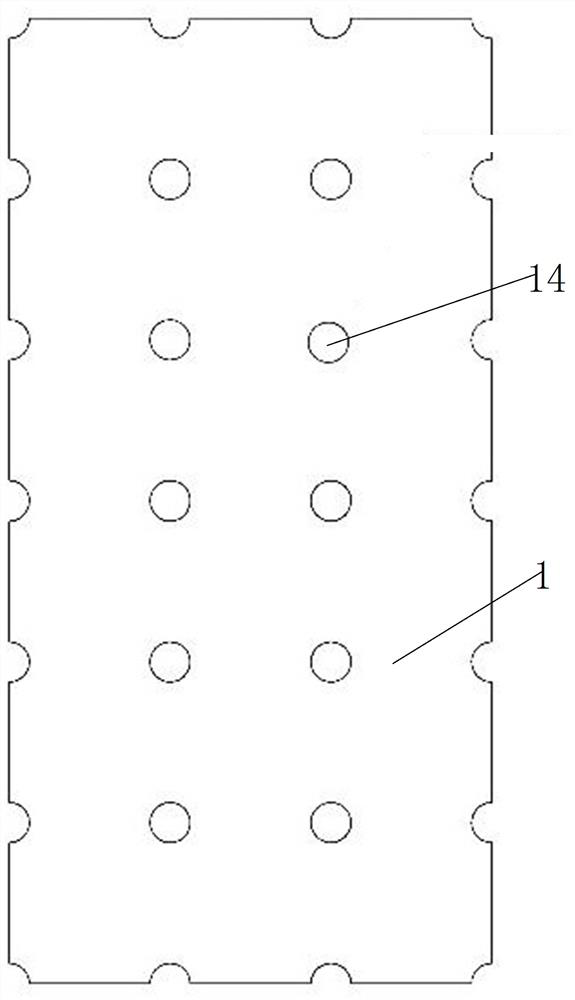

[0039] like figure 1 As shown, an anti-radiation airgel composite roll material includes an airgel felt 11, and the upper and lower surfaces of the airgel felt 11 are respectively wrapped with metal foils 12.

[0040] Note that the role of the metal foil 12 here is not only to block heat radiation, but also to protect the airgel felt 11, so it should be thicker on the premise that it does not affect the bending and the processing conditions permit. Make it unbreakable with fingernails, so as to keep it intact during handling and cutting.

[0041] The airgel blanket 11 and the metal foil 12 are glued and connected by a flexible adhesive, and the flexible adhesive fills the gap between the airgel blanket 11 and the metal foil 12 . The flexible adhesive here refers to the adhesive that remains soft after curing. The selection of the flexible adhesive has two functions. One is to avoid affecting the bending of the airgel felt 11, and the other is to form a glue that covers the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com