High-airtightness, high-protection-grade and high-compactness lighting device

A compact lighting and high-protection technology, applied in the field of lighting, can solve the problems of insufficient process execution, substandard waterproof effect, and substandard assembly products, etc., to simplify installation and production processes, avoid human factors and raw material factors, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

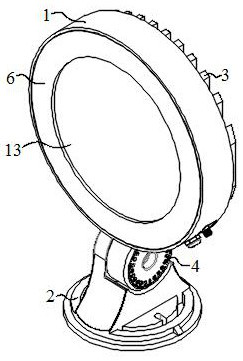

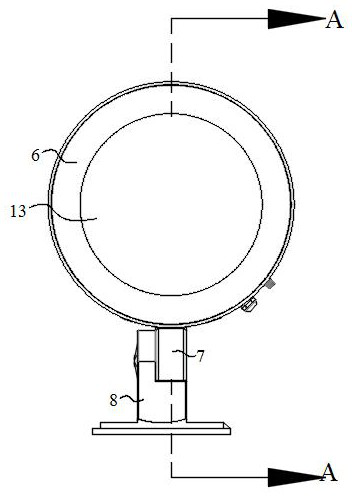

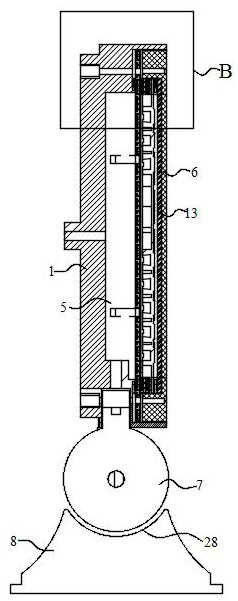

[0036] refer to Figure 1-8 , high airtightness, high protection level, and high compact lighting device, including a housing 1, a connecting plate 10, a cover plate 6, a light source assembly, and a power supply assembly 5; The side plate 14 on the side is composed of a cavity structure, and the surface of the bottom plate 15 facing the inside of the cavity structure is the front; the connecting plate 10 is arranged in the cavity structure of the housing 1 and divides the cavity structure into a power supply cavity. and the light source cavity, the connecting plate 10 includes a first side and a second side, and the face opposite to the front of the bottom plate 15 is the first side; between the first side of the connecting plate 10 and the front of the bottom plate 15 The power supply chamber is formed, and the power supply chamber is used to accommodate the power supply assembly 5; a heat conduction pipe 25 is arranged in the power supply chamber, and the heat conduction pi...

Embodiment 2

[0051] refer to Figure 9 with Figure 10 , the first lateral surface of the supporting base 2 of the lighting device in this embodiment is fixedly connected to the bottom plate 15 of the casing 1, and the rest are the same as in the first embodiment.

Embodiment 3

[0053] The vacuum pumping principle of the lighting device of the present invention:

[0054] refer to Figure 8 , by pressing the core rod 35 at the air outlet end of the valve core, the spring 34 is compressed, and at the same time, the core seat sealing ring 38 and the first stopper 39 leave the first positioning portion 37, and the intake air of the valve core airflow channel 33 The opening is opened to connect the inside and outside of the lighting device. After the air in the cavity of the lighting device is sucked out by vacuum equipment, the pressure is removed. The first positioning part 37 of the valve core moves until it touches it completely, and the air inlet of the airflow channel 33 of the valve core is sealed again, so that the cavity is in a vacuum state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com