Pinion and rack clamping mechanism

A technology of clamping mechanism and rack and pinion, which is applied in the direction of drilling equipment, earthwork drilling, drilling pipes, etc., can solve the problems of short life of thrust bearings, the chuck cannot be opened empty, etc., and achieve a large clamping range and lifting efficiency And the effect of versatility and wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

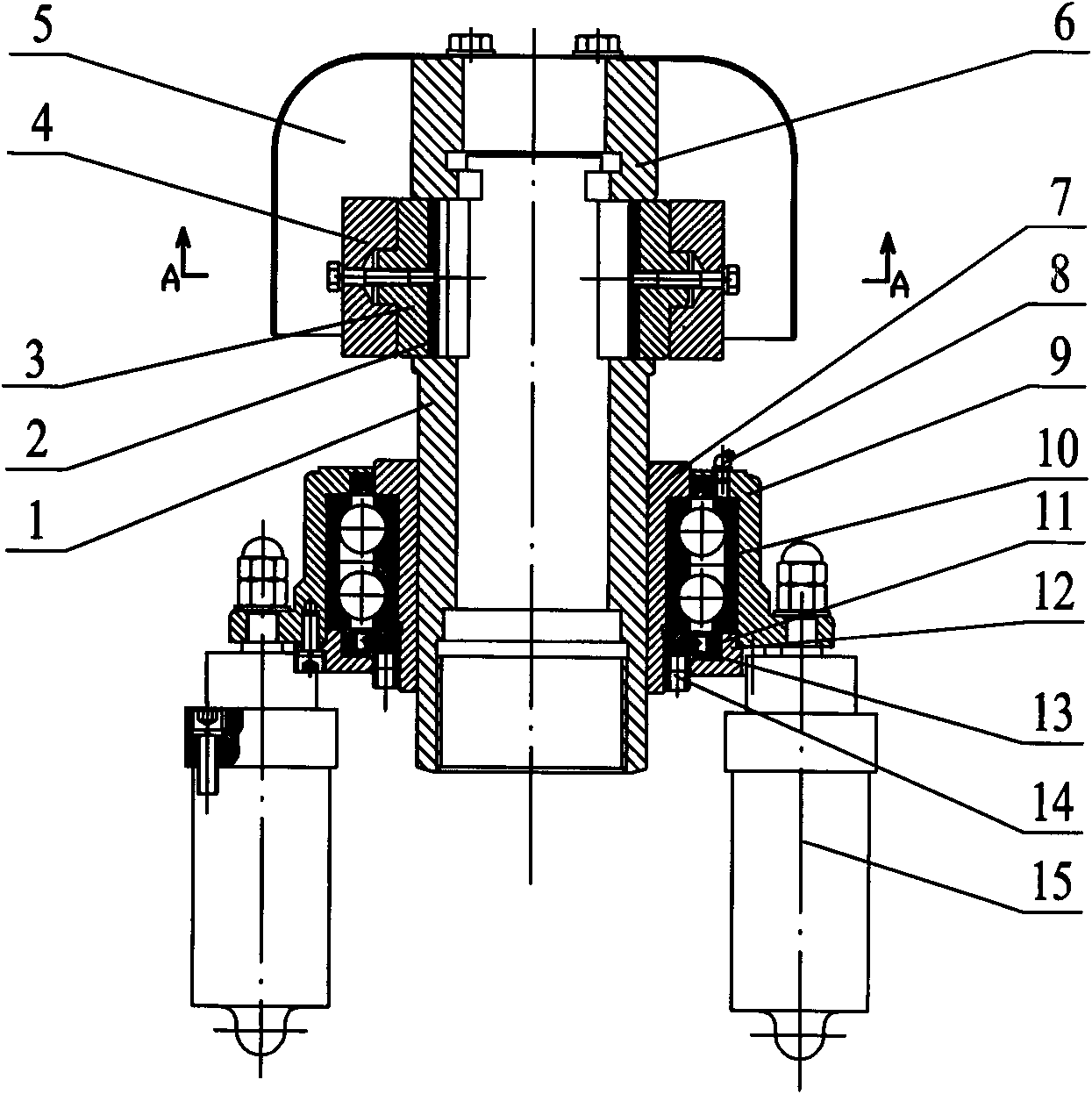

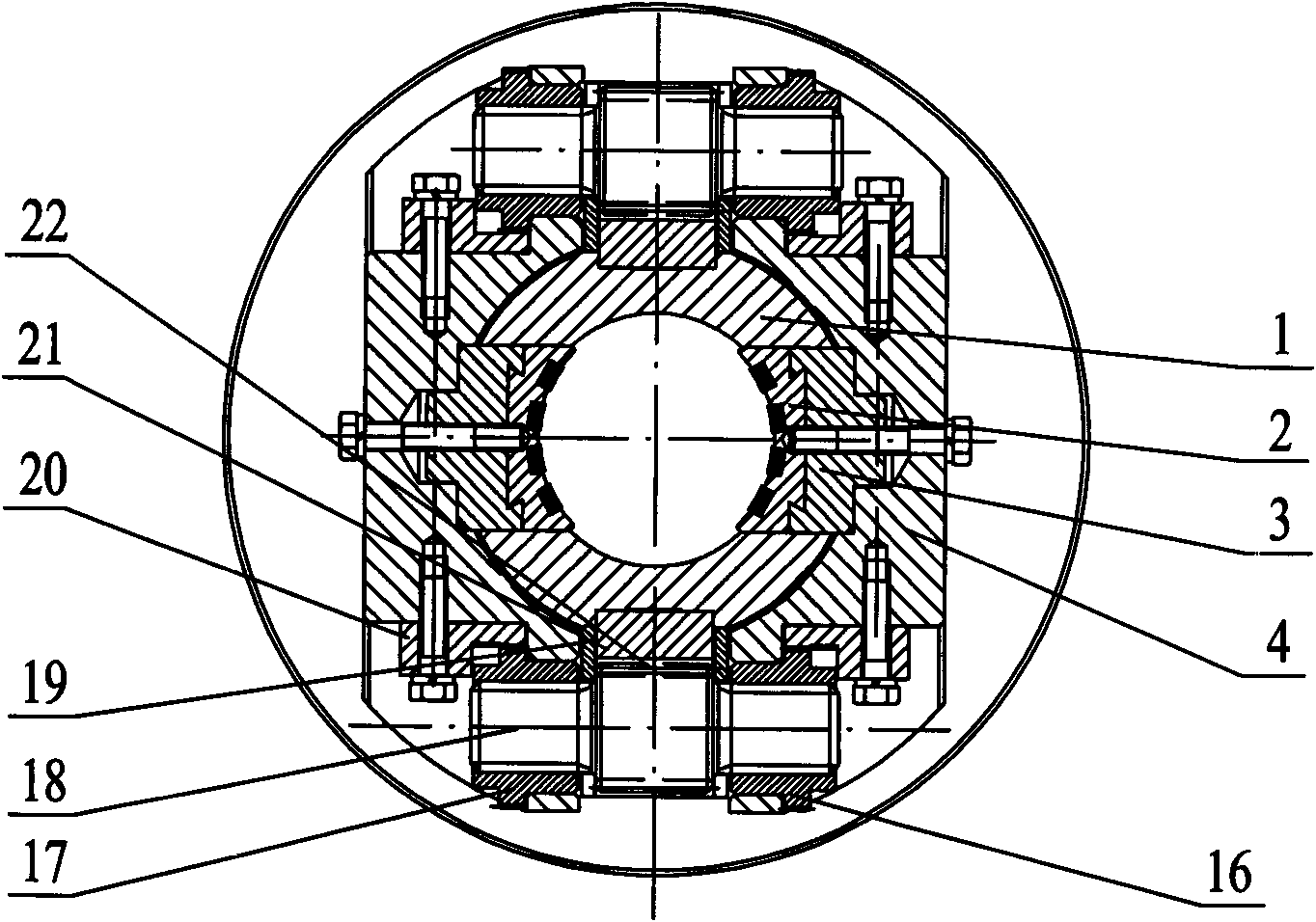

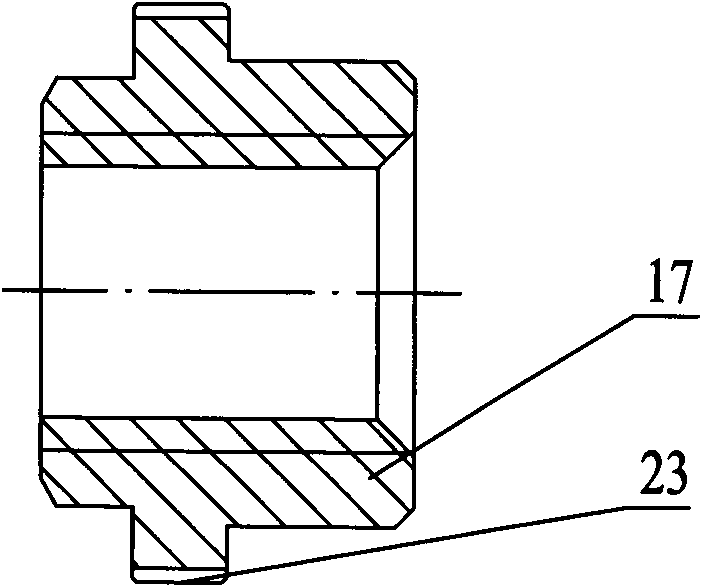

[0019] As shown in the figure, the present invention mainly includes clamping parts, transmission parts and power parts installed on the chuck seat 1, mainly consisting of the chuck seat 1, slips 2, slip pads 3, slip seats 4, chuck Tile cover 5, upper cover of chuck seat 6, rack seat 7, oil cup 8, bracket 9, bearing 10, oil seal 11, cover 12, lock nut 13, back nut 14, chuck oil cylinder 15, right-handed belt teeth Nut 16, left-handed toothed nut 17, chuck gear rod 18, positioning card 19, stop block 20, tooth bar 21 and fasteners and other components are assembled; fasteners are mainly made up of bolts and washers.

[0020] Such as figure 1 Shown, power part among the present invention is chuck oil cylinder 15, and chuck oil cylinder 15 is installed on the pressure beam of drilling rig by bolt, washer, and its piston rod end is installed bracket 9 by nut, wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com