Planar nano gas sensor, array and preparation method thereof

A gas sensor, planar technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems that hinder the development of intelligent sensing of gas sensors, precise detection of difficult target gases, poor selectivity, etc., achieve low power consumption, reduce Effect of operating temperature, full exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

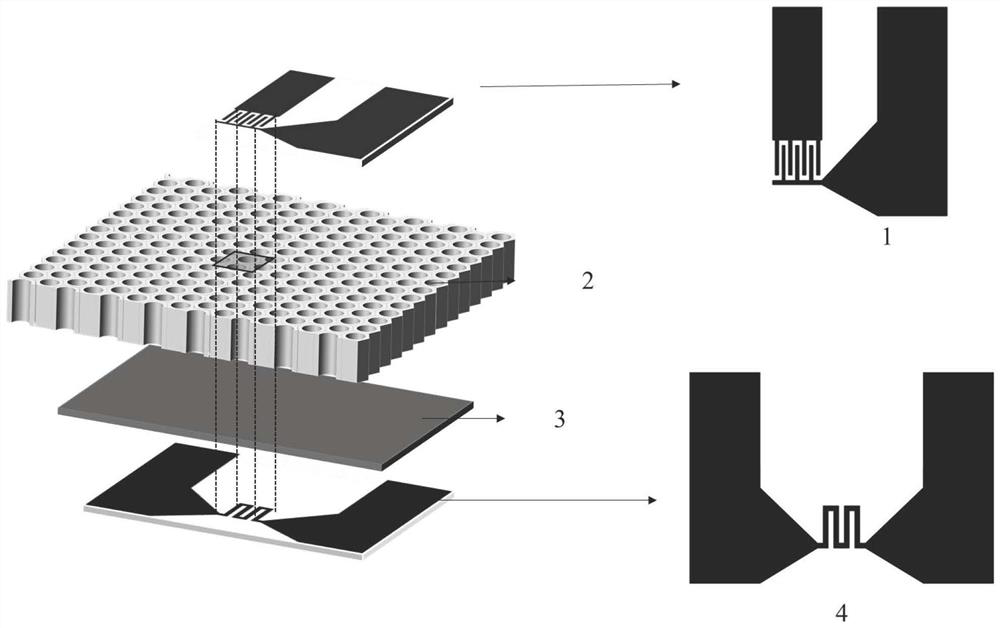

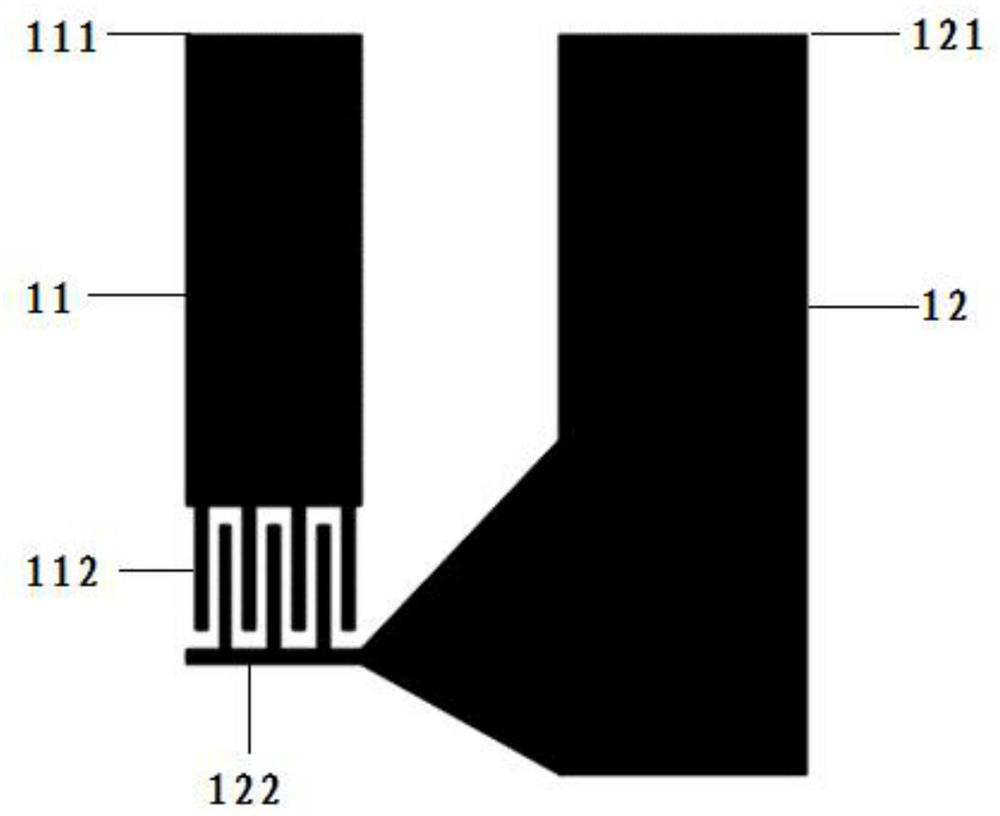

[0055] Such as figure 1 As shown, a double-hole planar nano gas sensor provided in this embodiment includes a planar sensing electrode 1 , a sensing layer, an electrical insulating layer 3 and a micro heater 4 in order from top to bottom.

[0056] The sensing layer is formed after depositing nano-scale sensing materials in a double-hole substrate; the double-hole substrate is composed of a plurality of double-hole nanotubes; the double-hole nanotubes The tube is a nanotube with one end and the other open, and one end communicates with the other end; wherein, the nanoscale sensing material is deposited on the tube wall of the double-through-hole nanotube.

[0057] The heating area of the micro-heater overlaps with the sensing area of the planar sensing electrode in the vertical direction.

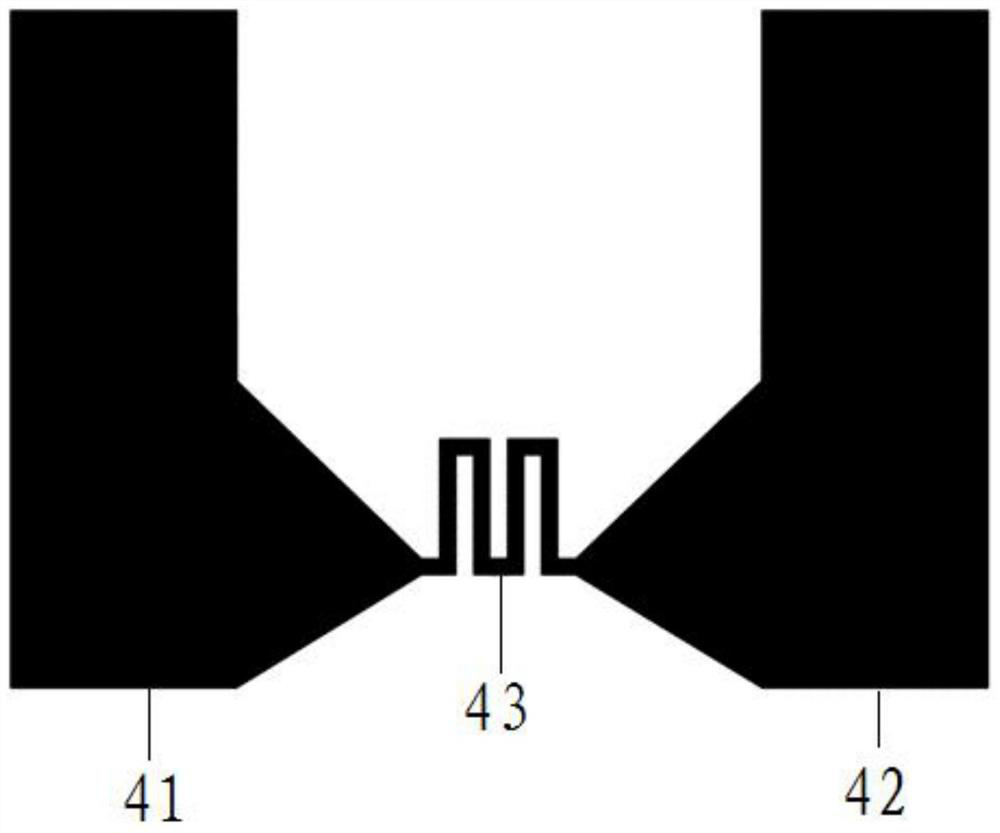

[0058] As a preferred specific implementation, the micro heater 4 provided in this embodiment is as figure 2 As shown, it includes a heating wire 43 and a first heating electrode 41 a...

Embodiment 2

[0068] This embodiment provides a method for preparing a double-through-hole planar nano-gas sensor described in Embodiment 1. The structure of the double-through-hole planar nano-gas sensor is as described in Embodiment 1, but here More description. Its preparation method is as Figure 8 shown, including the following steps.

[0069] Step S11: Deposit nanoscale sensing materials in the double-through-hole substrate to form a sensing layer, that is, after the deposition is completed, there will be nano-scale sensing materials on the upper and lower surfaces of the double-through-hole substrate and the inner walls of the nanotubes.

[0070] Preferably, the sensing material provided in this embodiment is SnO 2 、TiO 2 , ZnO or other metal oxide materials, the double-through-hole substrate provided in this embodiment is a double-through-hole 3D anodized aluminum template; the thickness of the double-through-hole anodized aluminum (AAO) template provided by this embodiment It i...

Embodiment 3

[0086] Such as Figure 5 As shown, a single through-hole planar nano gas sensor provided in this embodiment includes a planar sensing electrode 1 , a sensing layer and a micro heater 4 in order from top to bottom.

[0087] The sensing layer is formed after depositing nanoscale sensing materials in a single-hole substrate; the single-hole substrate is composed of a plurality of single-hole nanotubes; the single-hole nanotube The tube is a nanotube with one end open, the other end sealed, and one end connected to the other end; wherein, the nanoscale sensing material is deposited on the tube wall of the single through-hole nanotube.

[0088] The heating area of the micro heater 4 overlaps with the sensing area of the planar sensing electrode 1 in the vertical direction.

[0089] As a preferred specific implementation, the micro heater 4 provided in this embodiment is as figure 2 As shown, its micro-heater 4 is the same as the micro-heater described in Embodiment 1, and wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com