Automatic conveying and stamping device for high-strength bolts after normal-position arrangement

A technology of high-strength bolts and stamping devices, applied in forging/pressing/hammer devices, bolts, operating devices, etc., can solve problems such as scalding oneself, threatening personal safety, and high bolt temperature, so as to avoid injuries, ensure personal safety, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

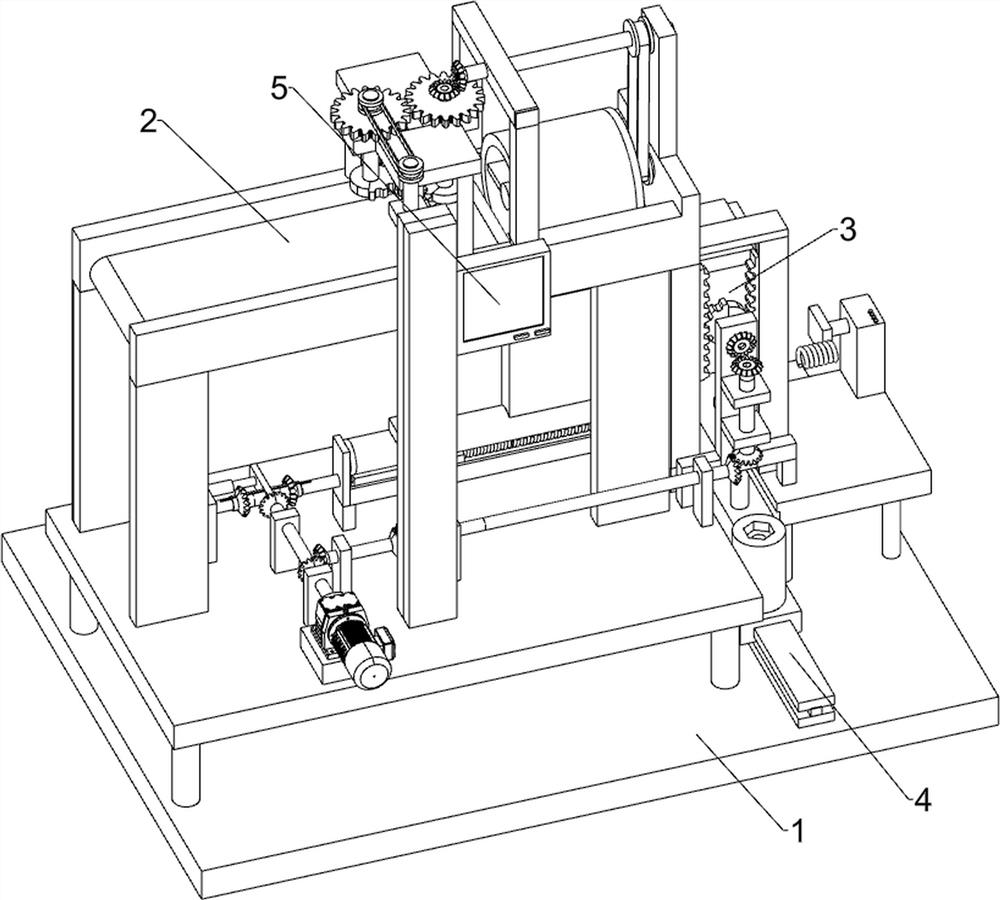

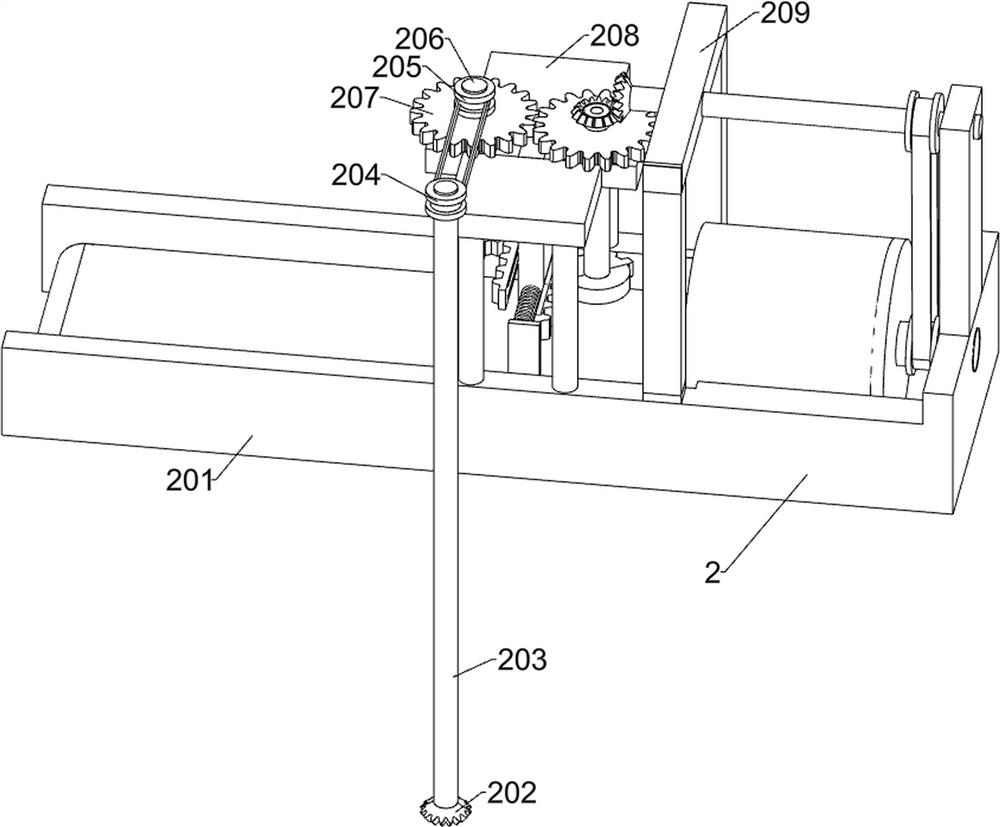

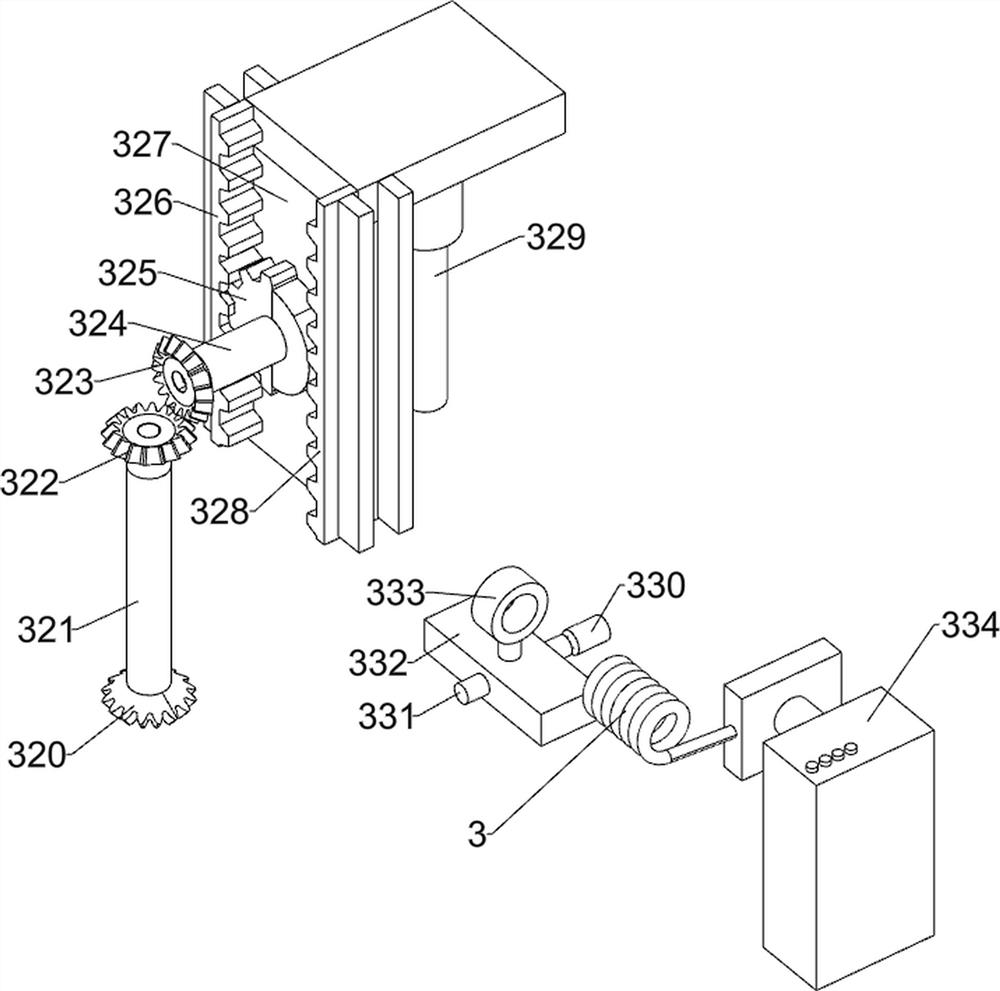

[0030] A stamping device for automatic transmission after high-strength bolts are aligned, such as Figure 1-10 As shown, it includes a bottom plate assembly 1, an arrangement transfer unit 2, a heating and softening unit 3, a stamping forging unit 4 and a control panel 5; the bottom plate assembly 1 is connected to the arrangement transfer unit 2; the bottom plate assembly 1 is connected to the heating and softening unit 3; The bottom plate assembly 1 is connected with the stamping and forging unit 4 ; the bottom plate assembly 1 is connected with the control panel 5 ; the arrangement transfer unit 2 is connected with the heating and softening unit 3 .

[0031] When using, first arrange a high-strength bolt in the right position, then automatically transfer the stamping device to the position to be used, then connect the external power supply, and start it through the control panel 5; The arrangement and transfer unit 2 in the bottom plate assembly 1 then uses the arrangement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com