A marine water divider processing device capable of cleaning pig iron powder powder

A technology of processing device and water separator, applied in the direction of cleaning methods and tools, manufacturing tools, cleaning methods using tools, etc., can solve problems such as labor-consuming and troublesome, and achieve the effect of saving labor and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

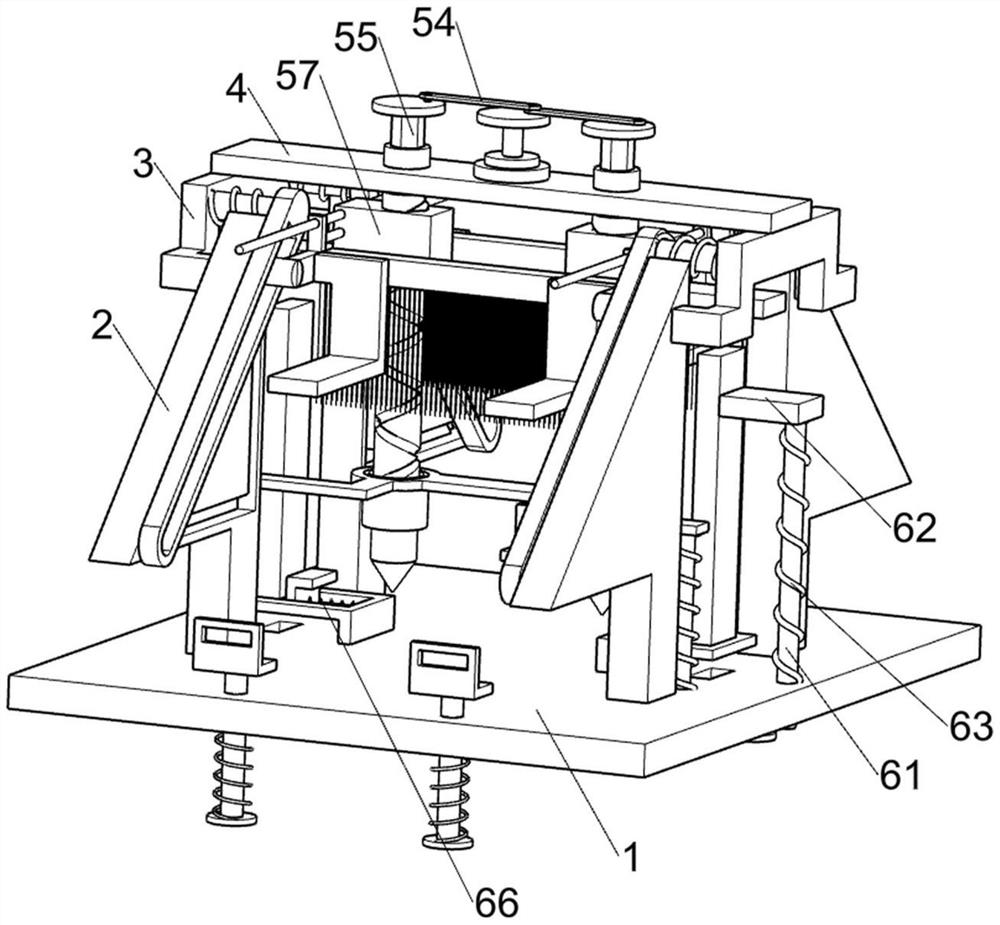

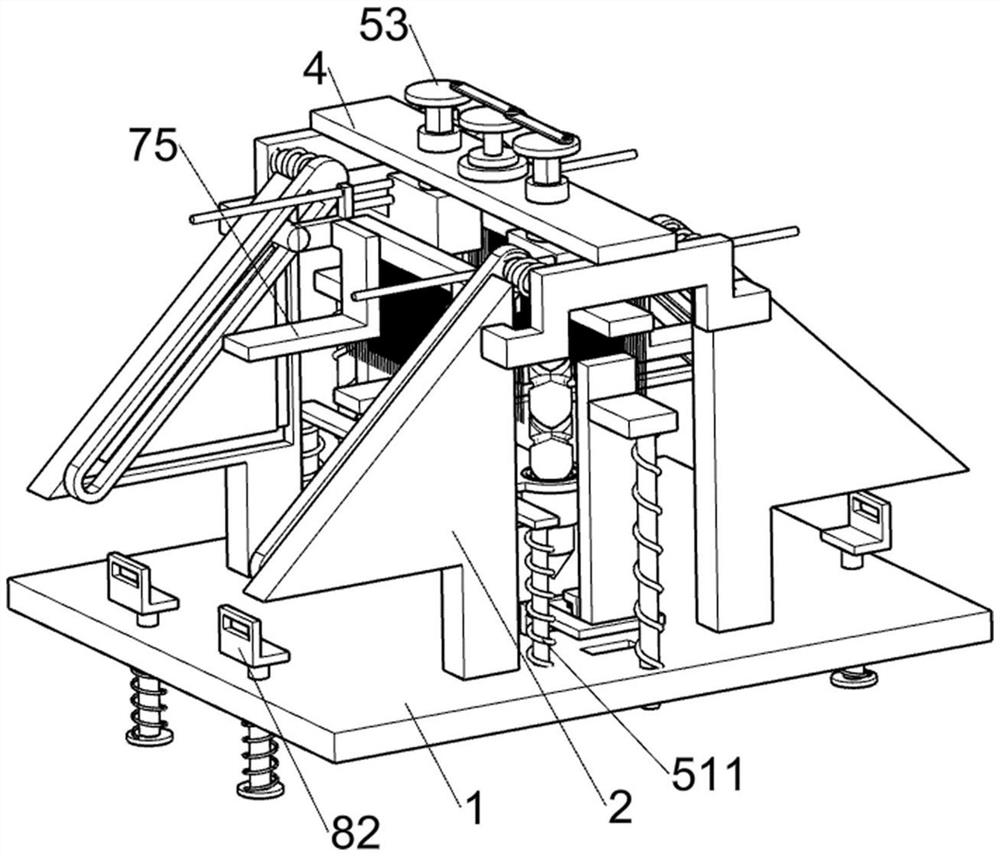

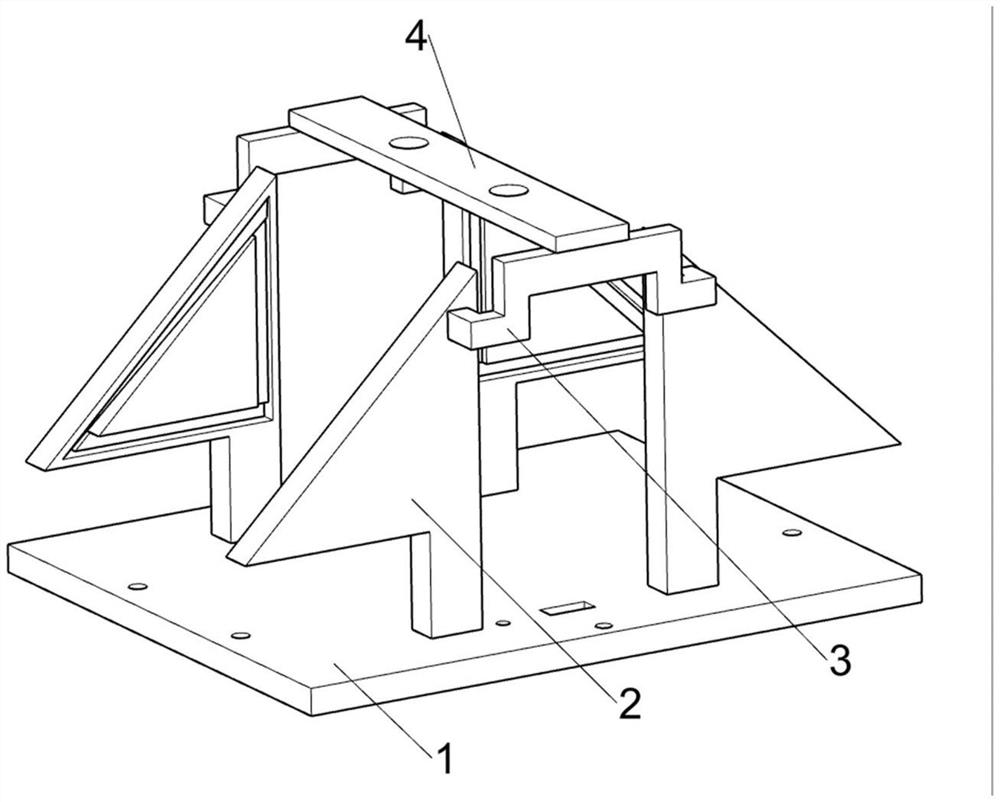

[0026] A marine water divider processing device that can clean pig iron powder powder, such as Figure 1-8 As shown, it includes a perforated slotted bottom plate 1, a triangular guide frame 2, a special-shaped fixed connection frame 3, an open-hole rectangular support frame 4, a reciprocating down-pressing drilling mechanism 5, a pressing mechanism 6, a swing jack mechanism 7 and a pull-up mechanism Bending mechanism 8, a pair of triangular guide frames 2 are symmetrically fixed on both sides of the top of the perforated slotted bottom plate 1, and the triangular guide frames 2 are used to make the sliding round rod 73 and its upper device move along the upper chute, and the two triangular guide frames on the same side are guided A special-shaped fixed connection frame 3 is fixed between the upper part of the frame 2, and the special-shaped fixed connection frame 3 is used to support the open-hole rectangular support frame 4 and the slotted swing rod 71, and the top of the two...

Embodiment 2

[0034] On the basis of Example 1, as Figure 8 As shown, a brush 9 is also included, and the brush 9 is fixedly connected between the two sliding round bars 73 on different sides.

[0035] When the sliding round rod 73 descends to the bottom of the chute on the right-angled side of the triangular guide frame 2, the sliding round rod 73 will drive the brush 9 to move to contact with the top of the iron plate, and then when the sliding round rod 73 slides along the lower part of the triangular guide frame 2 When the groove moves horizontally, the brush 9 will move away from each other along with the sliding round rod 73, and clean up the pig iron scraps left by the holes on the top of the iron plate. When the sliding round rod 73 is reset, the sliding round rod 73 will Drive the brush 9 to reset together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com