New energy automobile battery recycling device

A new energy vehicle and battery recycling technology, applied in the direction of transportation and packaging, rotary conveyors, conveyor objects, etc., can solve the problems of wasting time, inconvenient recycling, easy missorting of energy, etc., to prevent the arrangement from getting stuck, Time-saving, convenient recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

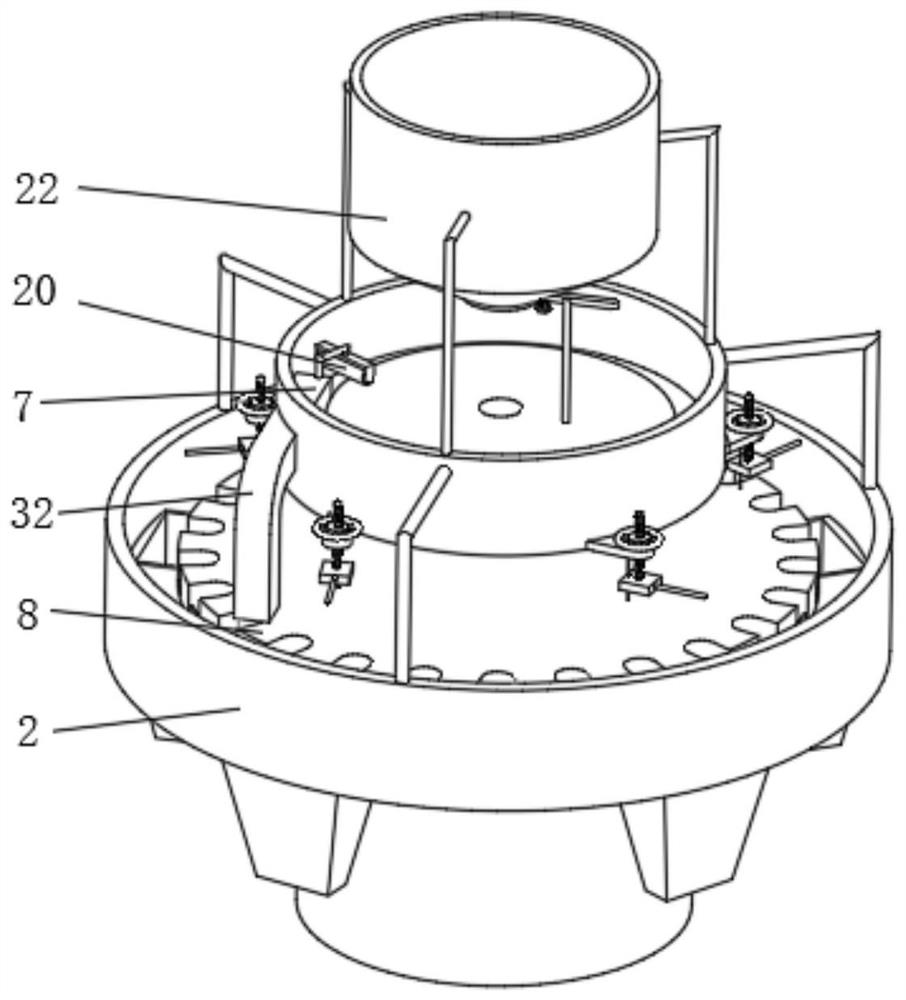

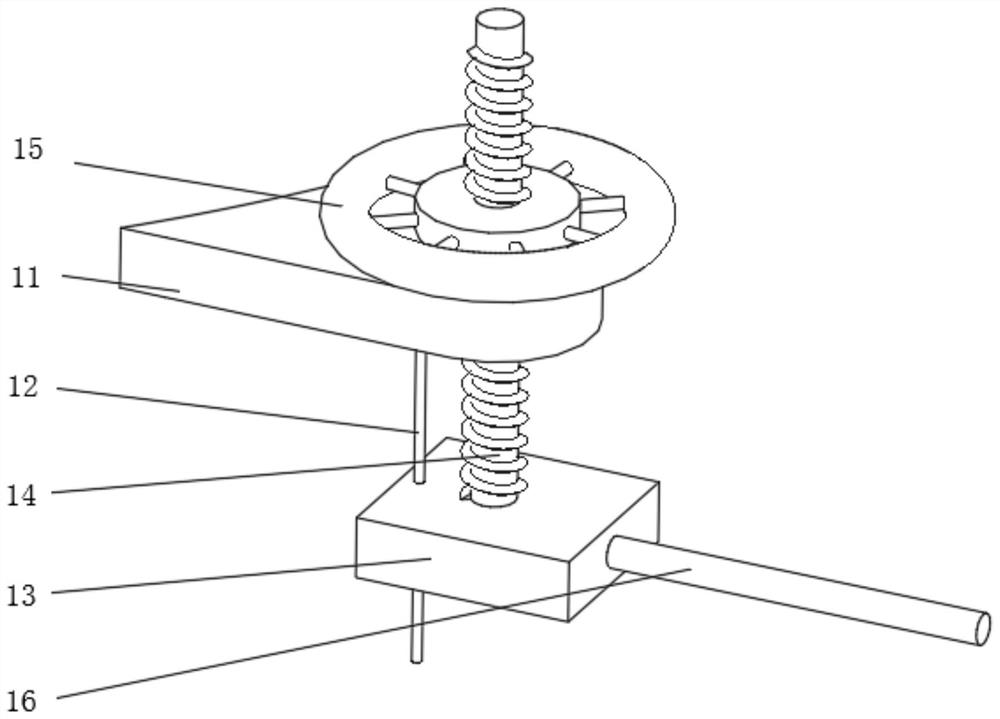

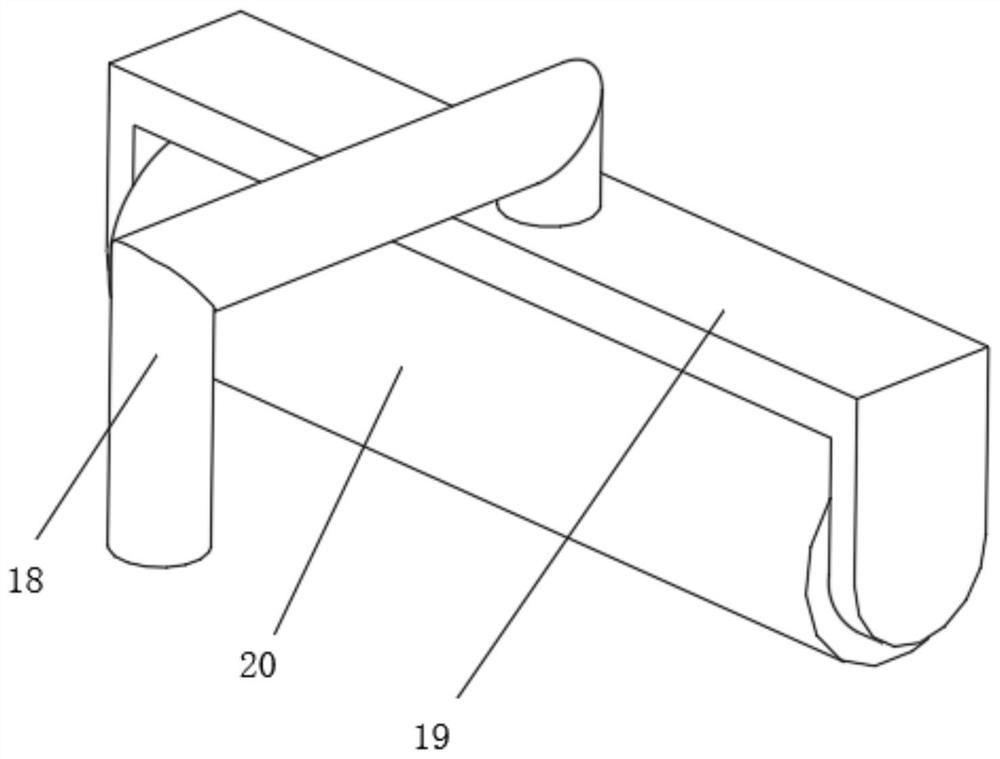

[0042] Example: Reference Figure 1-8 A battery recycling device for new energy vehicles shown includes a bottom platform 1, a sorting cylinder 2 is fixedly installed on the top side of the bottom platform 1, and the top side of the sorting cylinder 2 is fixedly installed with the same arrangement through a plurality of support frames 3. cylinder 4, the inner wall of the bottom side of the arrangement cylinder 4 is rotatably mounted with a rotating disk 5, and the top side of the rotation disk 5 is fixedly mounted with a ramp disk 6, and one side of the arrangement cylinder 4 is provided with a square hole. A slot frame 7 is fixedly sleeved in the square hole, and a conveying pipe 32 is fixedly installed on one side of the slot frame 7. A sorting disc 8 is arranged in the sorting cylinder 2, and multiple An adjustable separation mechanism.

[0043] By means of the above mechanism, when the individual battery falls onto the ramp plate 6, under the action of the ramp plate 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com