Three-dimensional integrated anaerobic fermentation equipment

An anaerobic fermentation, integrated technology, applied in the direction of organic fertilizer equipment, preparation and application of organic fertilizer, can solve the problem of inability to discharge, avoid accumulation and blockage, and ensure the effect of closure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

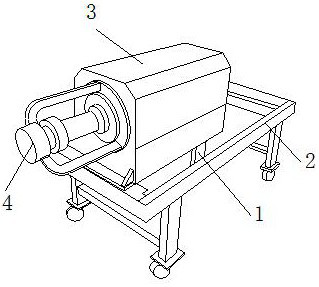

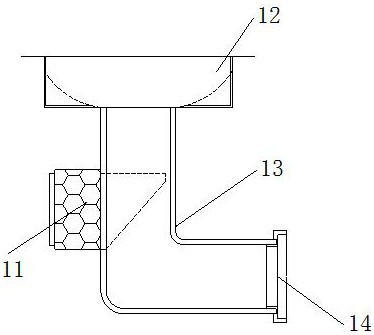

[0029] as attached figure 1 to attach Image 6 Shown:

[0030] The present invention provides a three-dimensional integrated anaerobic fermentation equipment, the structure of which includes a drainage pipe 1, a bracket 2, a fermentation tank 3, and a heating rotating rod 4, the drainage pipe 1 is embedded and installed on the lower surface of the fermentation tank 3, The bracket 2 is inlaid and engaged with the fermenter 3, and the left end surface of the fermenter 3 is inlaid and engaged with a heating rotating rod 4, and the heating rotating rod 4 is located above the left side of the drain pipe 1; The drainage pipe 1 includes a collection device 11, a collection pool 12, a hollow pipe 13, and a nozzle cover 14. The collection device 11 is inlaid and fitted on the inner end surface of the hollow pipe 13, and the collection pool 12 is located on the front side of the collection device 11. Above, the inner end surface on the right side of the hollow tube 13 is nested with a...

Embodiment 2

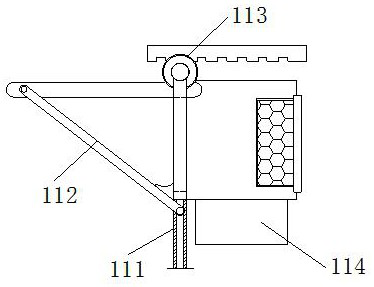

[0038] as attached Figure 7 To attach Figure 9 Shown:

[0039] Wherein, the linkage device 113 includes a latching rod 131, a closing plate 132, and a latching gear 133. The latching rod 131 is inlaid and fitted directly below the latching gear 133, and the closing plate 132 is located on the latching rod 131. Directly above, the outer end surface of the locking gear 133 is inlaid and engaged with the closing plate 132. The left end surface of the closing plate 132 is made of rubber. When the locking gear 131 and the locking gear 133 are driven to the left , the closing plate 132 can be pressed against the inner wall of the hollow tube 13 to close the end surface.

[0040] Wherein, the closing plate 132 includes an inlaid plate 321, an embedding block 322, an extruding plate 323, and a wrapping ring 324. The lower end surface on the left side of the inlaying plate 321 is embedded with an embedding block 322, and the embedding block 322 The inlay is arranged directly below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com