Paper pulp extrusion auxiliary equipment capable of automatically adjusting height according to amount of paper pulp

A technology of automatic adjustment and auxiliary equipment, applied in the direction of papermaking, papermaking machines, pressing parts, etc., can solve the problems of non-separation, pulp damage, affecting paper quality, etc., and achieve the effect of accelerating water evaporation, speeding up pulp air drying, and improving dehydration efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

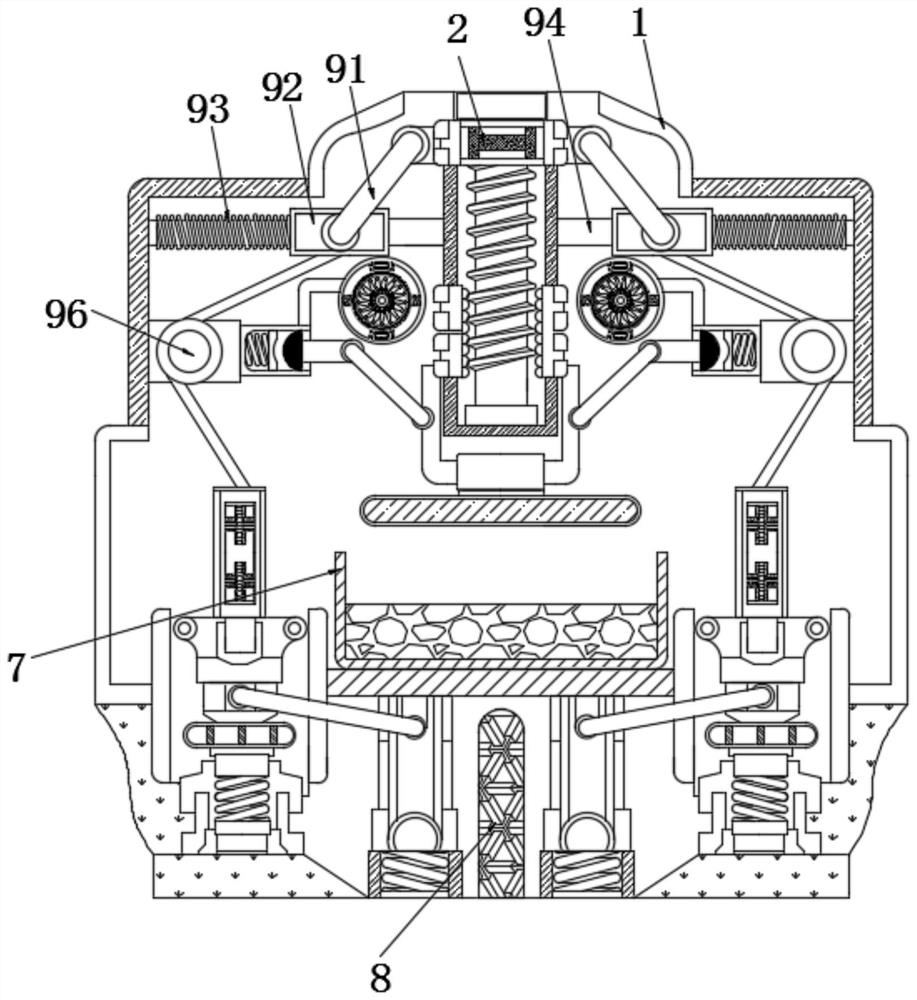

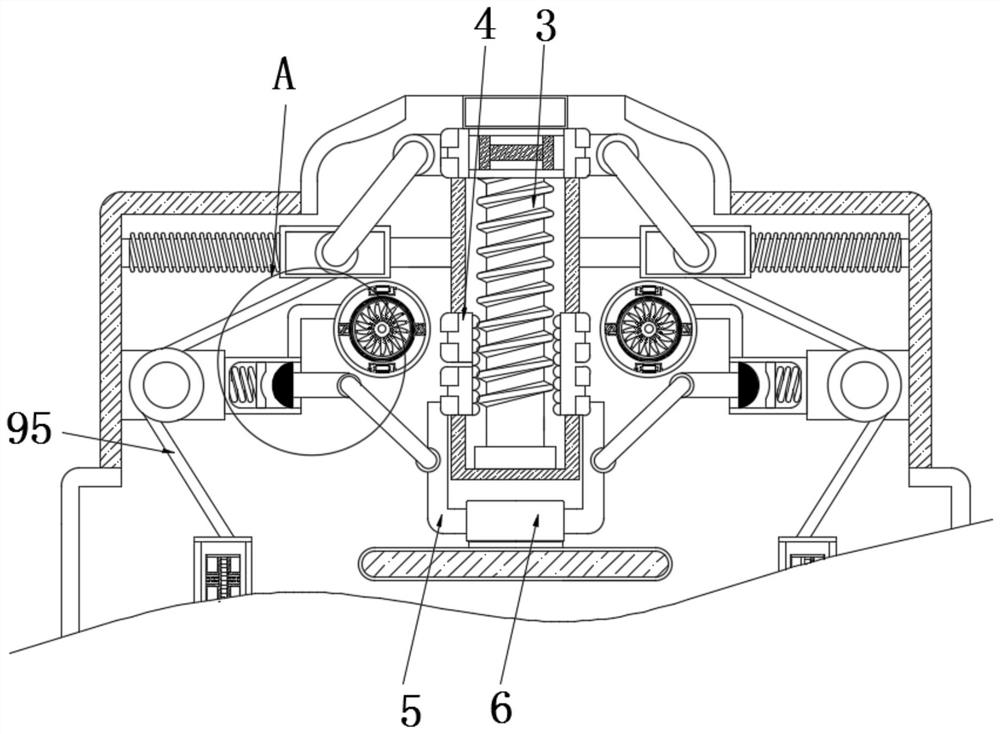

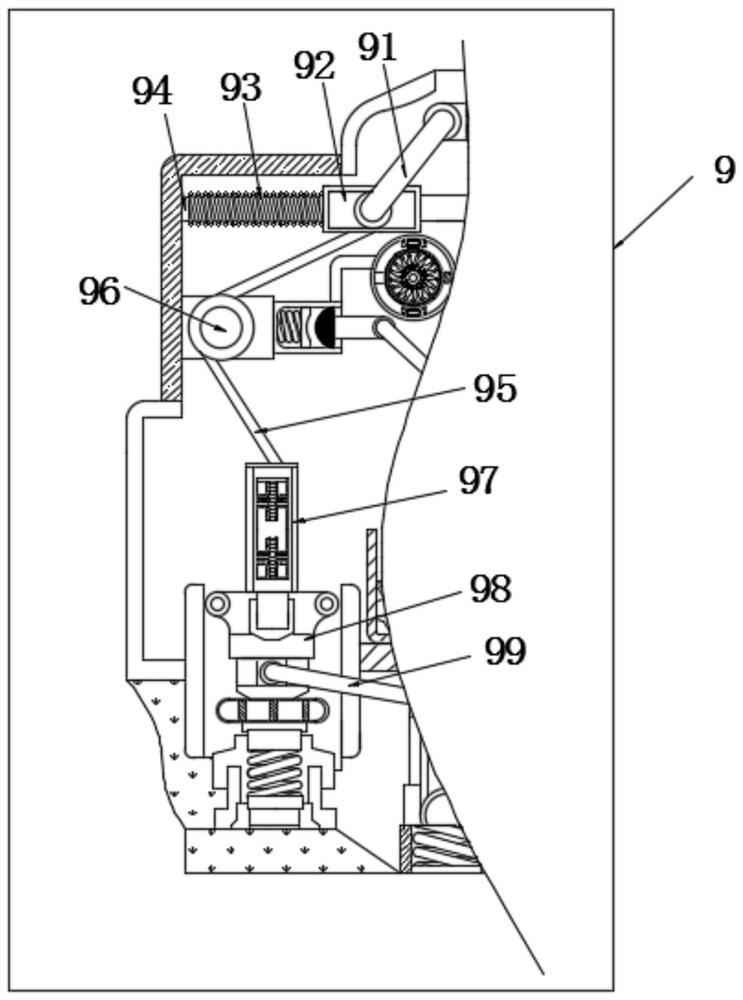

[0026] A pulp extrusion auxiliary equipment that automatically adjusts the height according to the amount of pulp, including a processing table 1, the inner top surface of the processing table 1 is fixedly connected with a telescopic rod 2, and the lower surface of the telescopic rod 2 is fixedly connected with an adjusting screw 3, and the adjusting screw 3 The left and right sides of the lower end of the telescopic rod 2 are meshed with a slider plate 4, and the left side of the telescopic rod 2 is movably connected with an adjustment assembly 9. The adjustment assembly 9 includes a pull rod 91, and the lower end of the pull rod 91 is movably connected with a positioning slide plate 92, and the positioning slide plate 92 The lower surface is fixedly connected with a steel wire rope 95, the left side of the positioning slide plate 92 is fixedly connected with a support spring 93, the inside of the positioning slide plate 92 is plugged with a rectangular cross bar 94, and the in...

specific Embodiment approach 2

[0028] A pulp extrusion auxiliary equipment that automatically adjusts the height according to the amount of pulp, including a processing table 1, the inner top surface of the processing table 1 is fixedly connected with a telescopic rod 2, and the lower surface of the telescopic rod 2 is fixedly connected with an adjusting screw 3, and the adjusting screw 3 The left and right sides of the lower end of the telescopic rod 2 are meshed with a slider plate 4, the left side of the telescopic rod 2 is movably connected with an adjustment assembly 9, the lower surface of the adjustment screw 3 is fixedly connected with an L-shaped connecting rod 5, and the lower end of the L-shaped connecting rod 5 The extruding dewatering plate 6 is fixedly connected, and the inside of the processing table 1 is located below the extruding dewatering plate 6 and is slidably connected with a storage tank 7. At the midpoint between the two support frames 991, the inner bottom surface of the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com