Numerical simulation simplification method for resistance reduction performance of surface microstructure of rotating blade

A numerical simulation and rotating blade technology, applied in the field of computer simulation, can solve the problems of increasing the difficulty of simulation, the complexity of the impeller surface, and the high cost of calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

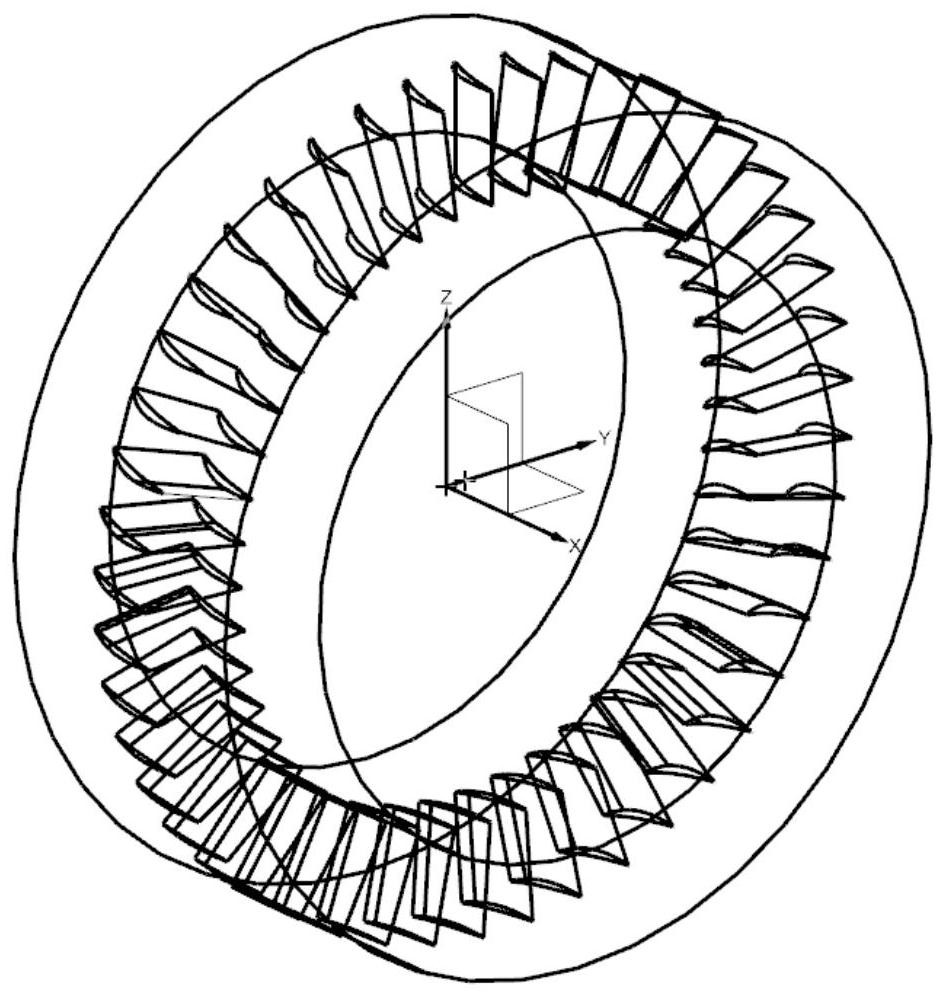

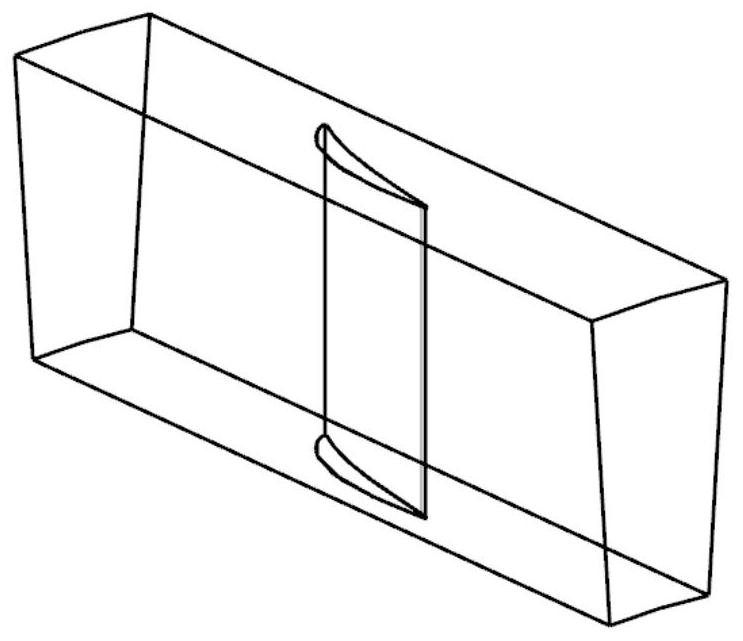

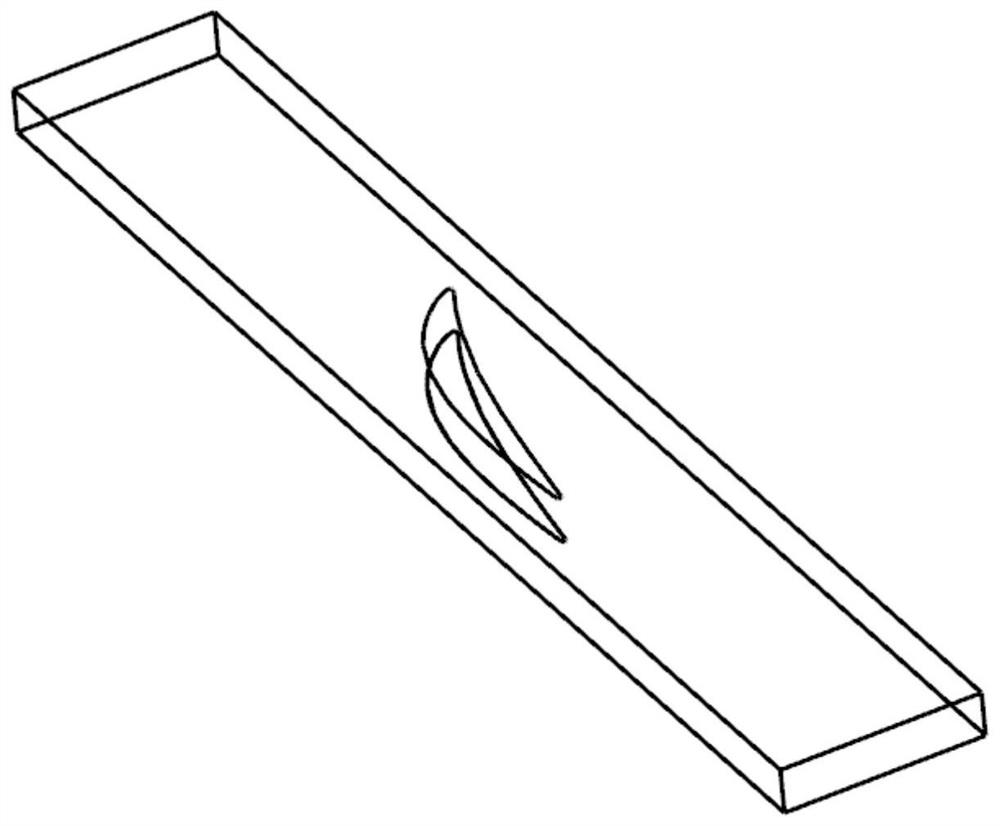

[0025] Simplify the numerical simulation method for the surface micro-texture of the rotating blade. Firstly, the calculation domain of the overall smooth impeller is established according to the overall smooth impeller model, and the numerical simulation of the whole ring of the smooth impeller is carried out. A single blade is selected for analysis to determine the flow field around the single blade. Angle of attack, velocity parameters. Secondly, the calculation domain of the overall smooth impeller is segmented, and the calculation domain of a single smooth blade is established, and the single-ring periodic numerical simulation of a single smooth blade is performed to extract the parameters of the angle of attack and flow velocity of the flow field around the blade. Compare with the results of full-ring simulation to ensure the rationality of the simulation from full-ring to single-ring. Then, the airfoil at a certain blade height position is selected, and the computationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com