Liquid heat-conducting medium injection pipe and heating device

A heat-conducting medium and heating device technology, applied in the direction of injection devices, injection devices, fluid heaters, etc., can solve the problems of easy overheating and uneven heating of heating pipes, and achieve enhanced turbulent flow intensity, elimination of fouling, and elimination of carbonization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

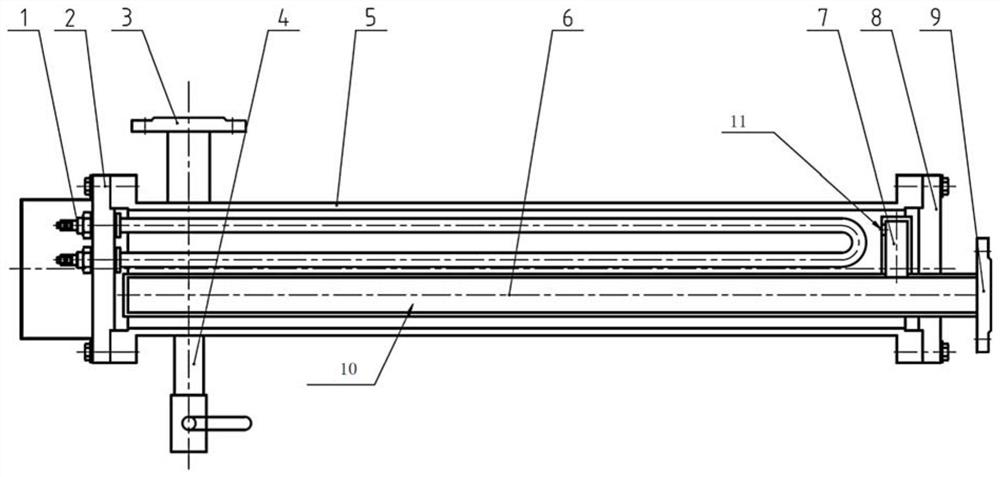

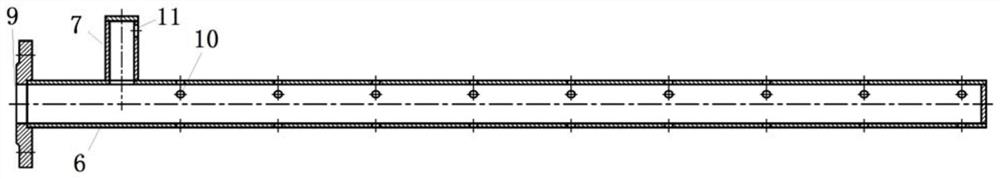

[0025] A liquid heat-conducting medium spray tube and a heating device using the spray tube, the heating device can effectively propagate dry burning. Such as figure 1 As shown, the heating device includes a housing 5, a first heat pipe end flange 2 and a second heat pipe end flange 8 respectively arranged at two ends of the housing 5, a heating pipe 1 installed in the housing 5, and a heat pipe passing through the second heat pipe end flange 8. The heat pipe end flange 8 is installed on the injection pipe in the housing 5; the heating pipe 1 is provided with a thermocouple; There is a liquid outlet 3 for the liquid heat transfer medium to flow out; the spray pipe has a liquid inlet 9, which is the liquid inlet 9 for the heat transfer medium of the entire heating device. The heating pipe 1 is a U-shaped pipe, and the inlet and outlet of the U-shaped pipe are installed on the first heat pipe end flange 2; the heating pipe 1 is located between the liquid outlet 3 and the main l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com