A particle type friction stir additive manufacturing device and method

A technology of additive manufacturing and friction stir, which is applied in the direction of manufacturing tools, additive processing, non-electric welding equipment, etc., can solve the problems of easy oxidation of materials to be added, and achieve the effect of less oxides, less impurities, and low storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

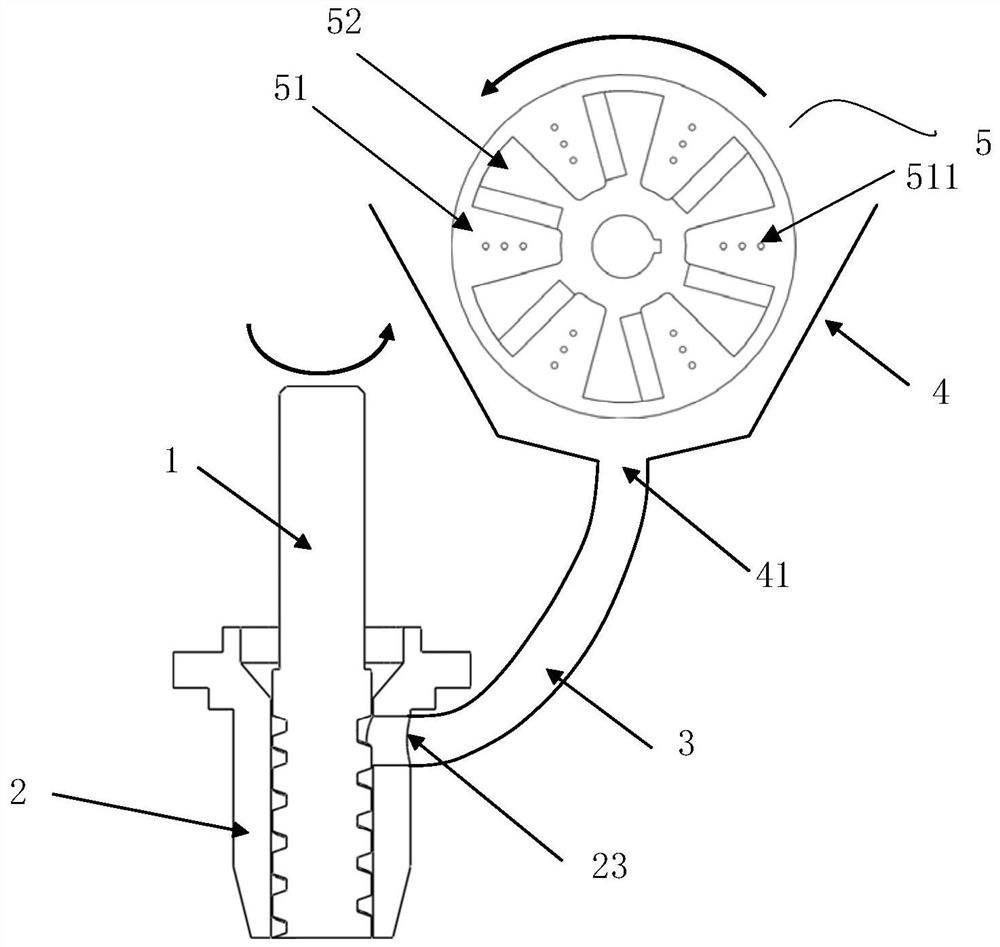

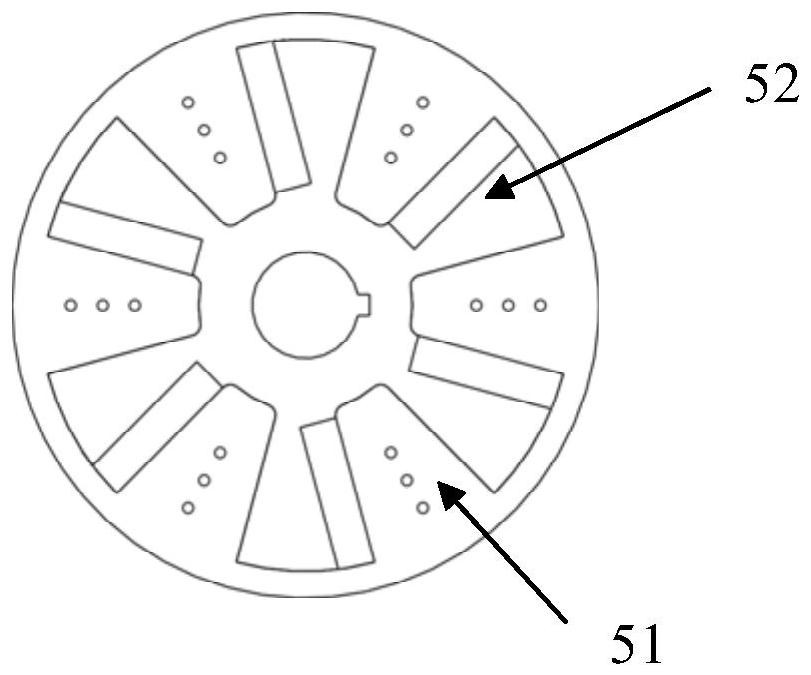

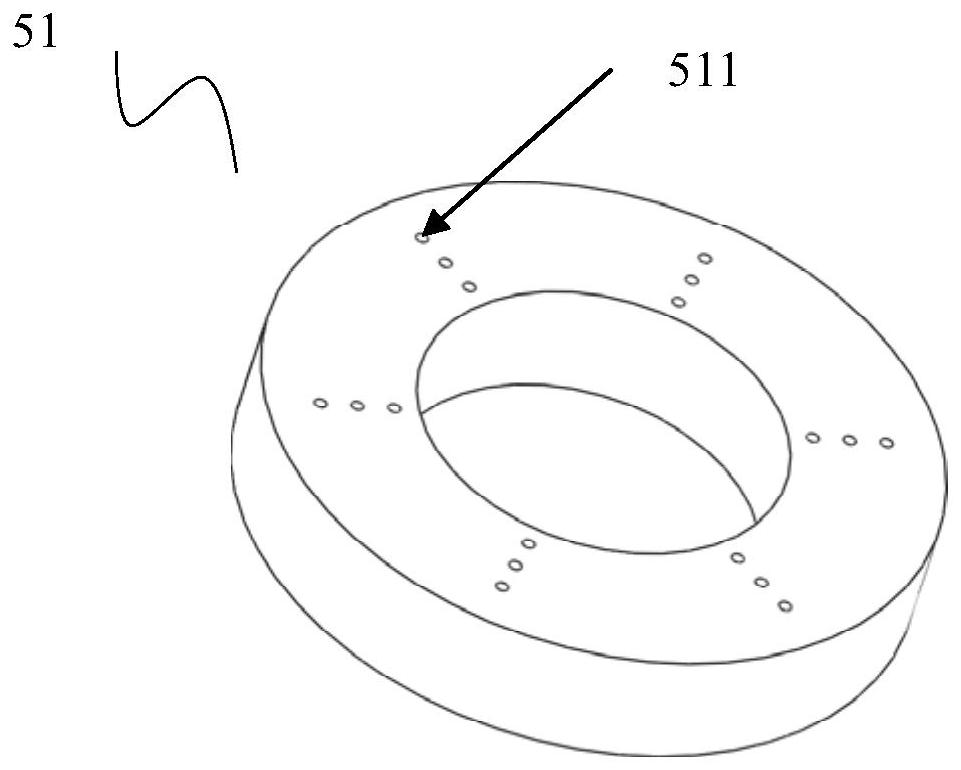

[0060] Figure 1-6 It is an embodiment of a particle type friction stir additive manufacturing device provided by the present invention, wherein, figure 1 Schematic diagram of the additive manufacturing device, figure 2 Schematic diagram of the wire cutting mechanism, image 3 It is a three-dimensional view of the base of the wire cutting mechanism, Figure 4 It is a three-dimensional view of the cutting part of the wire cutting mechanism, Figure 5 is the three-dimensional view of the stirring needle, Image 6 It is a perspective view of the static shaft shoulder.

[0061] like Figure 1-6 As shown, a granular friction stir additive manufacturing device provided by the present invention includes a stirring needle 1 , a static shaft shoulder 2 , a material guiding tube 3 , a collecting device 4 and a wire cutting mechanism 5 . Among them, the wire cutting mechanism 5 includes a base 51 and a cutting part 52. The base 51 is a disc-shaped structure with a hole in the cen...

Embodiment 2

[0068] Figure 8-9 The second preferred additive manufacturing device provided by the present invention, such as Figure 8-9 As shown, the difference from Embodiment 1 is that the static shaft shoulder 2 is divided into an upper part 21 and a lower part 22, and a bearing 6 is nested between the upper part and the lower part. Wherein, the upper part 21 of the shaft shoulder is fixed with the outer ring of the bearing 6 by means of a jack screw, and the lower part 22 of the shaft shoulder is fixed with the inner ring of the bearing 6 by means of a jack screw. In order to achieve a better sealing effect and prevent air from entering the static shaft shoulder, the bearing 6 is preferably a sealed bearing. At the same time, in order to make the bearing bear the downward pressure of the shaft shoulder, angular contact bearings, thrust ball bearings and thrust roller bearings are preferentially used. In order to realize the relative rotation between the lower part 22 of the shaft s...

Embodiment 3

[0071]This embodiment provides a particle-type friction stir additive manufacturing device, which includes the device described in Embodiment 1 or 2, as well as a spindle and a spindle drive motor. The main shaft includes a rotating shaft center and a stationary sleeve, the stirring needle 1 is fixed on the rotating shaft center, and the static shaft shoulder 2 is fixed on the stationary sleeve. The granular friction stir additive manufacturing equipment provided in this embodiment can adjust the wire material and diameter, wire feeding speed and wire cutting speed at any time during the additive manufacturing process, and automatically provide continuous and stable additive particles. . It avoids the problem of poor stability when the wire is directly fed for friction stir additive, and also avoids the problem of using powder or small particles for additive, which is easy to be oxidized, and the obtained additive parts have less internal impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com