Wear-resistant color master batch with antibacterial and anti-mite functions and preparation method of game pad by wear-resistant color master batch

A color masterbatch and functional technology, applied in the field of plastic coloring, can solve the problems of endangering the physical and mental health of infants and children, and children are prone to drooling, so as to inhibit the breeding of bacteria and mites, reduce the chance of infection and avoid mosquito bites Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Under normal temperature and pressure, send 0.5kg of pigment red, 8kg of titanium dioxide, 0.2kg of antibacterial agent, 0.5kg of citronella essential oil, 25kg of ultra-high molecular weight polyethylene, and 20kg of polyethylene resin to the stirrer, and the stirring speed is 100-120r / min. For 30 minutes, stir to mix evenly into a mixture. The mixture is put into a twin-screw extruder for extrusion granulation, the extrusion temperature is controlled at 190-210°C, extruded to form a strand, and then the strand is cooled by a water tank and then enters a pelletizer for granulation to obtain Wear-resistant masterbatch with antibacterial and anti-mite function.

Embodiment 2

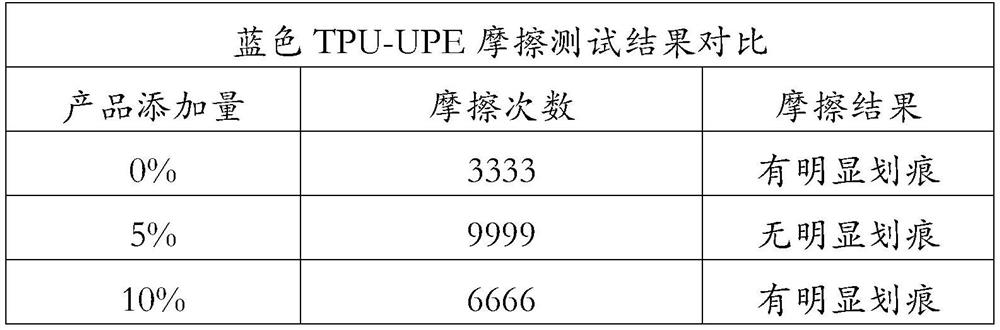

[0024] Under normal temperature and pressure, send 10kg of pigment blue, 1kg of pigment red, 12kg of titanium dioxide, 0.4kg of antibacterial agent, 1.5kg of citronella essential oil, 55kg of ultra-high molecular weight polyethylene, and 30kg of polyethylene resin to the mixer, and the stirring speed is 100-120r / min, 30 minutes, stirring and mixing evenly into a mixture. The mixture is put into a twin-screw extruder for extrusion granulation, the extrusion temperature is controlled at 190-210°C, extruded to form a strand, and then the strand is cooled by a water tank and then enters a pelletizer for granulation to obtain Wear-resistant masterbatch with antibacterial and anti-mite function.

Embodiment 3

[0026] Under normal temperature and pressure, send 9kg of pigment blue, 0.9kg of pigment red, 11kg of titanium dioxide, 0.3kg of antibacterial agent, 1.4kg of citronella essential oil, 53kg of ultra-high molecular weight polyethylene, and 28kg of polyethylene resin to the stirrer, and the stirring speed is 100~ 120r / min, 30 minutes, stirring and mixing evenly into a mixture. The mixture is put into a twin-screw extruder for extrusion granulation, the extrusion temperature is controlled at 190-210°C, extruded to form a strand, and then the strand is cooled by a water tank and then enters a pelletizer for granulation to obtain Wear-resistant masterbatch with antibacterial and anti-mite function.

[0027] Among the above, the antibacterial agent is formed by mixing isothiazolinones and silver ions. The isothiazolinones have a heterocyclic structure, and can rely on the active part on the heterocycle to destroy the DNA molecules in the bacterial cells, so that the bacteria lose a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com